544 Wiper Info

First Published Apr2016, R. Kwas, updates on-going [comments added]

Improved 544 Wiper Wiring Diagram

Component between Terms 53 and 31b

Park Function with Dynamic Braking

Reference information

544 Wiper Switch Information

-------------------------------------------------------------------------

I have have never owned one of these fine vehicles, but thought it was time to collect what info I have been able to research and deduce on this page, to help my 544 owning friends.

Wiper Systems installed on the 544 have less variations than those of the 122 and later models, but they are very different, as they use a Permanent Magnet Motor requiring Dynamic Braking. This also makes them a bit more complex, to make things pretty interesting when servicing or troubleshooting. Only single speed motors were ever fitted, (Reference: Single Speed Wiper Motors) and although the four wires running between Switch and Motor Assy might suggest that a dual speed motor was installed...it wasn't!...and the electrically powered Windshield Wiper Pump shown on factory Wiring Diagram is quite rare.

Picture of an SWF Wiper Motor Assembly. Cover is held in place with a wire

bale, and when removed, allows inspection/

replacement

of Motor Brushes. Gears and Park Switch mechanism is contained within die

cast base of the assembly.

The 544 Wiper Motor Assembly is a two stage Spur Gear design with Dynamic Braking. It is a SWF (confirmed, or Bosch, this is not confirmed) supplied unit, very similar to those fitted to Volkswagens of the era (Reference: Thread at The Samba), or even SAABs. The spur gear with Field Motor and Dynamic Braking design is quite different from later mechanisms fitted to 122s which had Field Motors and Worm Gear Mechanisms with no Dynamic Braking. Later models after the 122 and early 1800s again had Permanent Magnet Motors requiring Dy Br (more on that in the Wiper Systems Tech Article: Dynamic Braking). Important point to note is that 122 Wiper Motors and mechanisms cannot be fitted in a 444/544, although through an odd sizing coincidence, the rear window wiper mechanism of a 245 apparently can be!

Wipers for 12V sys are an Ignition Powered, Fuse 1 Circuit load, as the following Wiring Diagram excerpt shows. Switch and Motor Assy are shown simplified in the factory manuals and without internal details. Although four wires run between Switch and Motor, this does not mean Wiper Motor has two speeds. It confirms that Motor is a PM type requiring Dy Br, and this is done with the Green wire. This diagram also doesn't show the sequential nature of a multi-position pull-switch or Dynamic Braking contacts. I will add further details on internals of switch and Motor Assy as I develop them.

Excerpt of 12V Wiper System from 544 Wiring Diagrams showing Wipers and little detail (three Position Switch):

Extract from 12V 544

Wiring Diagram, showing Wiper related components and

connections. Four wires connect switch to Motor Assy to allow Dynamic

Braking, and a three position switch is shown (OFF, Wipe, Wipe & Wash) with P

terminal for the Electric Washer Pump, but this

arrangement is rare. The switch in this shop manual wiring diagram is also

shown in an in-between position with terminals 31 and 54 not connected to other

terminals of the switch...this is not correct. When in the OFF position,

terminals 31 and 31b should be shown connected!

6v Wiper System looks similar to the 12V sys, but it is powered by Fuse 4 (Two Position Switch):

Extract from 6V 544/210 Wiring

Diagram , showing Wiper related components and

connections. Wire colors, terminals and connections between Switch and

Motor Assy are similar (but not identical!) to the 12V version (some

terminal numbers change and Red and Blue wires are reversed to keep it

interesting...!), and wire

gauge/cross-sectional area, is unsurprisingly double that of 12V sys. Supply is also Ignition

Power, but by way of Fuse 4 (...oh goody!...you get to have

two 25A shorties!). A two position switch is shown correctly in the OFF position, with term 31 connected to 31b.

Picture of SWF Assy, posted in a response by Eric H. on Brickboard thread:

https://www.brickboard.com/RWD/volvo/1630843/444-544/wiper_motor_wiring_q.html

.

After some research and input from experienced experts like Jack A. from the vintage SAAB world (...and we wont hold that against him!...they apparently also used a version of this Assy), the internal details become clear:

From some SAAB manual (kindly provided by Jackson

Ashcraft)

Wiper Switch shown in the OFF position. Note closed 31 to 13b contact in this Switch

position,

which routes chassis return path to

Motor Assy (for Dy Br). Note also, that Cam (3) which actuates

Transfer Pin (4) and which operates the Dy Br contact, is shown in the

mid-travel (not Park!) position, so terminals 53 and 53a are making contact and

power would be routed to Motor to complete one wiping cycle.

Disassembled Wiper Motor Assembly, showing major subcomponents. The

Yellow Eccentric (Cam, 3) which

actuates the Park Switch is apparent, as is the Park Switch Assembly at

Red. PSA is

removable after first removing its cover. If this is possible (at

all) with Motor Assy installed, and how difficult it is, an owner who has done

this operation might send the author some feedback on it. Only three terminals are

apparent on this particular PSA (possibly a SAAB or VW version, where negative connections are likely

being made through chassis, because the assembly is hard mounted. On the

Volvo vehicles, the assy is soft mounted on rubber sound isolators, so these

also electrical insulating mounts need to be jumped with a discrete wire.).

Incorporating this information gives this Improved 544 Wiper Wiring Diagram showing internal detail:

Detailed 544 Wiper Wiring Diagram, contacts shown in the OFF and Parked

condition

(Terminal 53 is connected to 31b and Chassis (31) by way of Park Switch contacts.)

Added Snubber Diode (green) found

on later Motors*.

* Snubber diode is effectively across the closing contact of "Parkswitch", and minimizes its erosion when it open, stopping the inductive motor current (see also: Hot Switching vs. Cold-Switching a Contact ) . See below: Component between Terms 53 and 31b.

Switch position and function in original unchanged configuration:

1. OFF (Motor is powered by Park Switch and runs until Park Switch

transfers to Dynamic Braking to aid Motor stopping).

2. Wipe

3. Wipe & Washer Motor power

-----------------------------------

Park Function explanation for Motors with Dynamic Braking:

In the 544 (similar to later 1800) vehicles, where Dy Br is required, action of Park Switch is more complicated than in the 122, as not only does the Park Switch cut power when Wiper Motor / Wipers are at the Park position, but it subsequently (and immediately after that) connects the motor terminals to chassis (effectively shorting them) and this brings to motor to a fast stop. It does this in conjunction with the Wiper Switch. Wiper Switch of the these systems is also more complicated in that it not only applies power to the motor, but it also applies a negative chassis connection (only) in the OFF position.

-----------------------------------

Intermittent Wiper Control added. It must be of the type having both a closing and an opening contact. It cannot be the simple type having only a closing contact! Understand, the author has spend significant effort considering the details of this, so this information will be forwarded only against an engineering charge. Please contact SW-EM if interested in installing this feature.

The 544 Wiper Motor design is a Permanent Magnet Motor with Dynamic Braking (unlike a 122 or 1800 which use Field Motors with no Dy Br)...this makes adding an Int Wip Cont more difficult, but not impossible, because with Dy Br, a chassis connection is made by way of the Wiper Switch in the OFF position, and this connection MUST be opened by Int Wip Cont when activated (otherwise there would be an inadvertent short to chassis on the incoming power). This means that a typical Int Wip Cont with a simple closing contact is not suitable, but the Bosch 0 336 920 004 or Hella 5WA 001 871 04, which have separate closing and opening contacts, will play successfully with this system. These are hard to find, and expensive, so SW-EM does not supply these Int Wip Conts...customer must source these or a functional equivalent. UPDATE: I have recently located a suitable, reasonably priced, Int Wip Cont which would be a good option. Please e-mail for info.

Switch positions and function with Int Wip Cont wired:

1. OFF (If not in Park Position, Motor is powered by Park Switch and runs until Park Switch

transfers from applying power, to Dynamic Braking and Motor stops. After variable delay of Int Wip

Cont, chassis connection is removed by opening contact, and closing contact

applies power momentarily to Motor to move it away from Park position.

Park Switch then applies power to complete one cycle and Park it again.

Cycle repeats as long as Int Wip Cont is powered and cycling).

2. Wipe (Normally, takes precedence even with Int Wip Cont powered and

cycling in the background).

3. Wipe & Washer Motor power.

--------------------------------------

Service Note:

The Motor Assy is difficult to remove from the Wiper mechanism while installed in

vehicle! It is

simpler to remove the entire mechanism, then separate the Motor from the assembly.

Installing a two-Speed Motor:

Only single speed Motors were installed by Volvo (Reference:

Single Speed Wiper Motors), but

there is first hand account of a two speed Motor from a 140 being adapted and

mounted on a 544 mechanism (Reference:

#Krarup_two_speed_140_wiper_motor_into_a_544). An adapter mounting plate

was necessary for the Motor Assy, shortening the

bell-crank was necessary, and the Two-speed (plus Wash) Switch (Four Position?) obviously needed to come

along also, but apparently it can be done! The developer, Michael Krarup

of Switzerland, has sent pictures and details,

and I have collected them in a separate page, linked at Reference.

--------------------------------

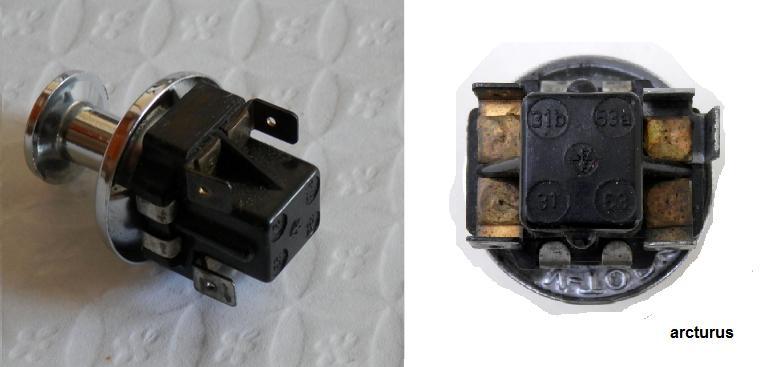

444/544 two-position Wiper Switch (OFF, Wipe) with no P terminal for Windscreen

Washer Motor. Single Speed, and used on 6 and 12V models.

Thanks to arcturus of the VOC Forum for supplying pix!

544 -122 Switch incompatibility: Again, an Amazon switch will not functionally replace this switch because it does not have the 31 and 31b terminals, (closed and connected when switch is in OFF position), which play with Park Switch in the Motor Assy. ...but if someone insists, or can't resist, and installs the Amazon switch, they can get Wipers to function after a fashion...depending on how they connect it, specifically, Park function might not work and Motor will stop immediately, without returning to Park position, whenever Switch is put to the OFF position.

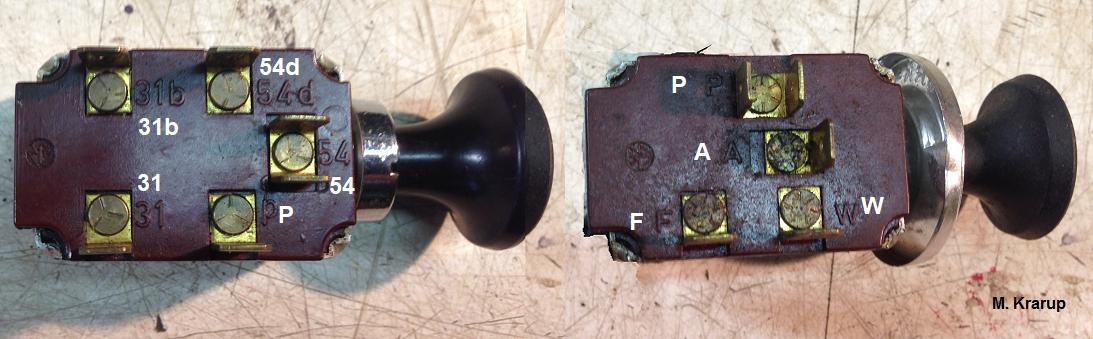

544 three position Wiper Switch on left (used on both 6 and 12V

installations, single speed, with P terminal for powering Windscreen Washer

motor) vs.122

four position switch on right. Thanks to M. Krarup for supplying pix

and application info!

--------------------

Spur Gears, from a popular reference source: https://en.wikipedia.org/wiki/Gear#Spur

From the same popular reference source under Dynamic Braking: "Dynamic braking can also be achieved by shorting the motor terminals, thus bringing the motor to a fast abrupt stop."

Worm Gears, from the same popular reference source: https://en.wikipedia.org/wiki/Gear#Worm

Only Single Speed Wiper Motors

were ever fitted to the 544: From Michael Krarup's posting:

https://www.brickboard.com/RWD/volvo/1631001/444-544/wiper_motor_wiring_q.html

"PV's never had two speed wipermotors, this was one of the reasons why the last

69 Duetts were sold as 68 models, because the law in Sweden was changed per

January 1st 69 that all cars had to have two speed wipers."

Michael Krarup has also adapted a Two-Speed 140 Motor Assy into a 544! I have collected all of this info here (republished with his kind permission), and he has also OK'd being contacted about it at the e-mail given, reader will have to correct his e-mail in the usual manner.

From our VW friends at the Samba:

http://www.thesamba.com/vw/forum/viewtopic.php?t=508707&view=next

"The single speed wiring shows a turning switch and Park Switch I expect would be

similar to the Volvo application."

----------------------------------

Sw-Em Technical Article: Windshield Wiper Systems

Thread from our VW driving friends at the Samba: 64 Wiper motor 6v to 12v build http://www.thesamba.com/vw/forum/viewtopic.php?t=389208

Jack Ashcraft, of the SAAB world looks at an SWF Wiper Motor Assy: http://saabjournal.blogspot.com/2015/01/volvo-544-windshield-wiper-motor-rebuild.html

More here: http://www.thesamba.com/vw/forum/viewtopic.php?t=509371

Brickboard Thread: https://www.brickboard.com/RWD/volvo/1581428/444-544/wiper_motor_issues.html

In scanning for Intermittent Wiper Controls, the inexpensive Velleman K2599 kit would be suitable. Delay timing is steps and not continuously variable. It is a simple kit without an enclosure, but has the requisite opening and closing contacts required (actually two independent relays controlled by the same timer). See: http://www.velleman.eu/products/view/?id=9019 Internal Wiring Diagram at: http://www.velleman.eu/images/tmp/K2599DIA.jpg

Component between Terms 53 and 31b Leads only remains of component between Terms 53 and 31b...what it is (or was), and what is its function [I expect it was a snubbing diode whose glass envelope didn't survive some mechanical insult), but would like independent confirmation...if you can help, or have a Wiper Motor assembly where this component is intact and can make some measurements with a DVM, please contact the author!]: (Link to thread looking for info): https://www.brickboard.com/RWD/volvo/1643299/444-544/component_term_31b_53_544_wiper_motors.html

Picture Credit: (Rainer07): Thread:

http://www.networksvolvoniacs.org/index.php/Spezial:AWCforum/st/id7223/Kohleb%C3%BCrstenhalter_Andruckfedern....html

544 Intermittent Wiper (after 12-6V Conversion) Notes by SW-EM Guest Contributor Richard Allen

------------------------------------------------------

Very good info from a Charles Greenlaw post on an older Brickboard Thread: https://www.brickboard.com/RWD/volvo/690885/444-544/544_wiper_wiring_problem.html

------------------------------------------------------

External material sources are attributed. Otherwise, this article is Copyright © 2016-2024. Ronald Kwas. The terms Volvo, VW, Bosch, SWF and Velleman are used for reference only. I have no affiliation with any of these companies other than to try to keep their products working for me, help other enthusiasts do the same, and also present my highly opinionated results of the use of their products here. The information presented comes from my own experience and carefully considered opinion, and can be used (or not!), or ridiculed and laughed at, or worshipped, at the readers discretion. As with any recipe, your results may vary, and you are, and will always be, in charge of your own knuckles, and future!

You are welcome to use the information here in good health, and for your own non-commercial purposes, but if you reprint or otherwise republish this article, you must give credit to the author or link back to the SwEm site as the source. If you don’t, you’re just a lazy, scum sucking plagiarist, and the Boston Globe wants you! As always, if you can supply corrections, or additional objective information or experience, I will always consider it, and consider working it into the next revision of this article...along with likely the odd metaphor and probably wise-a** comment.