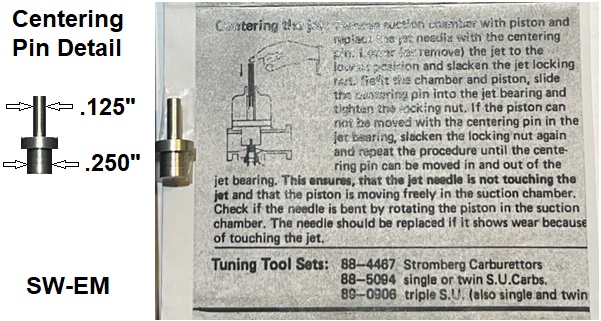

What's going on here? The Jet is shown lowered into the Choked position...besides the fact that the brass Jet Tube

is not brass colored, but silver, (from a previous application of Graphite grease on my part!...I just can't help myself!)

SU Jet Bearing and Supply Tube Notes

May 2017, R. Kwas, updates on-going [Comments Added]

------------------------------------

Initial Mixture Setting and

Adjustment

Considering the Jet Bearing

Centering the Jet

Procedure for Centering SU Jet

Final Check of Jet

Alignment

Reference Information

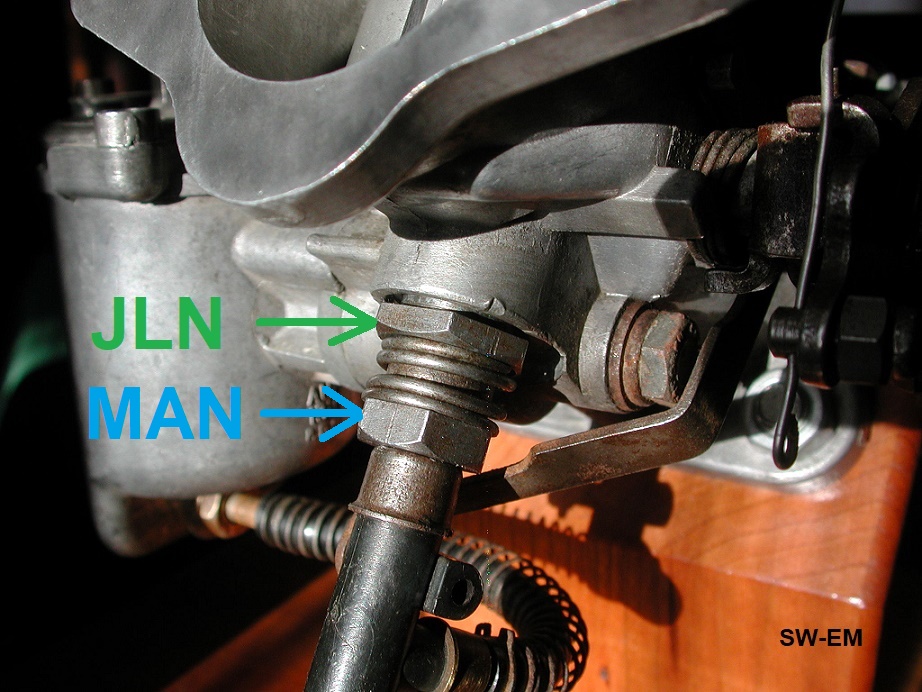

Centering Pin Detail

------------------------------------

Recent questions caused me to look in some detail further into the Jet Supply Tube and associated components. These components and their adjustment are what determines Fuel-Air Mixture, so are pretty critical. This is a compilation of what I found, and was able to put together.

What's going on here? The Jet is shown lowered into the Choked

position...besides the fact that the brass Jet Tube

is

not brass colored, but silver, (from a previous application of Graphite grease on

my part!...I just can't help myself!)

Jet Bearing Assembly, Exploded Detail:

Exploded assembly diagram showing Jet and Jet Bearing Assembly installation into carb body. Jet

Holding Screw(28) secures Jet Bearing(26) into carb body (with lateral

clearance, allowing the ever-important Jet Centering), and Mixture Adjustment Nut(30) varies

the depth of Jet itself into the Bearing allowing setting of initial

mixture, as well as fine adjustment of mixture, as detailed below.

The observant reader will notice there is no provision present for holding the Jet preloaded into Bearing! It is actually held there strictly by way of the return spring of the Choke Linkage (not shown in the diagram). The Adjustment Nut Spring(29) strictly preloads against the Mixture Adjustment Nut(30), and secures it in-place and from moving on its own!

Initial Mixture Setting and Adjustment: When replacing a Jet with new, or just reassembling after a major service where the locations of these components may have been changed, initial set-up (for mixture) should start from: Jet flush with Jet Bearing surface, then lowered 2 full turns (or "12 flats" of the Mixture Adjustment Nut(30)). This will allow engine to start...then one can proceed with fine-tuning of the mixture. According to my careful calculations, the 12 flats of adjustment are 0.0769" down from flush...detailed here:

Here are pictures of a Jet Bearing removed from Carb Housing and by itself for clarity, with Mixture Adjustment Nut(30) and Jet, but no Adjusting Nut Spring(29) or Jet Holding Screw(28) installed, to allow seeing the Jet Bearing threads.

|

|

| MAN is adjusted such that Jet is level/flush with Jet Bearing surface at venturi (Yellow). Note number of Threads visible above JAN (Blue). | MAN is adjusted two turns (12 flats CCW) such that Jet is below with Jet Bearing surface at venturi (Green). Note number of Threads visible above MAN (Blue). This is 0.0769" down according to calculations below. |

Threadcount of Jet Bearing over 1/2" is 13, so

Threadpitch of MAN is 26.

1/26 works out to 0.0385" per rotation of Jet (0.0063 per flat), or face will be 0.0769" down from level/flush with two turns/12 Flats.

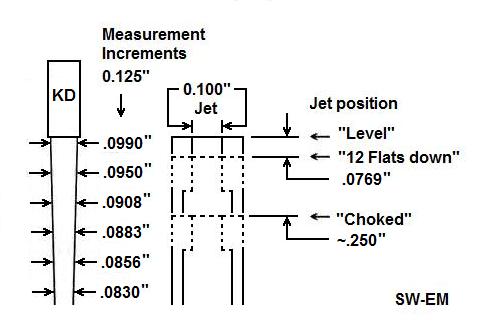

To better picture this, here is a little dimensional study to show approximate Metering Needle to Jet orifice clearance, at three key operating conditions: Flush or Level with top of Tube, 12 Flats down, and Choked. It should be noted that this calculation does not take into account the amount Dashpot rises (typically around another 0.125", depending on Idle) as a result of ingested Air.

Clearance between NM and Jet at Flush (or "Level") is a only 0.001" =(0.100" - 0.099"),

so one can see that concentricity is pretty important, lest they interfere and

jam...!

At 12 Flats down is approx

0.003" =(0.100" - 0.097"), and at Choked approx. 0.0092 =(0.100" - 0.908").

The point of this is to shown how literally a few thousands of an inch make all the difference between lean and "rich as hell", and how adjusting the mixture "one Flat" richer for winter operation is a change of mere ten-thousands of an inch!!!

------------------------------------------------------

Occasionally, and typically only after major carburetor work (with disassembly/removing/replacing the Jet Assembly) has been done, the dashpots do not fall completely to the Venturi. This is caused by a misalignment of the two, a situation must be corrected before returning the car into service(!), as it may be caused by the Metering Needle making contact with the Jet (...and they should never!...both are of soft brass, and contact will cause wear and changing the critical dimensions of the needle, affecting the mixture...clearly quite undesirable!).

The reader will notice that there is only a single thousandths of an inch dimensionally between the 0.100" Jet and the last station of the MN at 0.099", so there is only a small window in which the alignment is right!

The Jet Bearing seen here is nearly perfectly centered in the carb housing when

the Metering Needle...

but that does not necessarily mean the Jet is concentric with the MN in the Dashpot,

and that is the target here!

Jets need to be "centered", and NOT (necessarily) in their clearance hole in the carb housing/body as seen above, but with respect to the Metering Needle, which is secured into the Dashpot, which is in-turn riding in an oil film in the guide-tube of the Dome, which is in-turn secured to the carb housing, so the overall alignment is a combination of several clearances and alignments!. These critical components (Carb Housing, Dashpot, Dome) were precision machined, selected and paired at the time of manufacture, with the final adjustment being the slightly variable position of the Jet Bearing, so it stands to reason that if a Jet Assembly is moved for any reason, Jet MN alignment must be checked and OK before carb will operate properly in service.

Alignment can actually be simply checked, any time Air-Filter is removed so that Dashpot is visible, and also the MN and Jet interface, when Dashpot is lifted and allowed to drop back down. It should drop back down with a bit of a thunk completely closing the airflow path past Venturi (thunk indicating an abrupt contact), opposed to a silent stopping, and that before closing Venturi completely, as MN jams into Jet. If Dashpot does not fully drop closed audibly, determining the cause, and likely alignment and centering of the Jet will be necessary!

Adjusting Jet centering can be done by trial and error, and this is probably simple for those with lots of experience performing the operation, but those of us who only find we need to center a Jet Assy once in a blue moon, using a Centering Pin (a tiny tuning aid tool from one of those cute little SU Tuning Tool Kits) can really be helpful in achieving success without having to repeat the operation multiple times. By replacing the MN with the CP, then replacing dashpot, the alignment can quickly be checked, and that without risking damage to the NM. [...under the principle of: You can't hurt that which is not present! (Corollary to the saying: That which is not present can't hurt you! ...as applied to the Throttle Overrun Valve, also found on the SU!)]

See Reference info: Centering Pin Detail.

Suggested Procedure for Centering SU Jet (Note: Mixture Adjustment Nut is not involved in this procedure!):

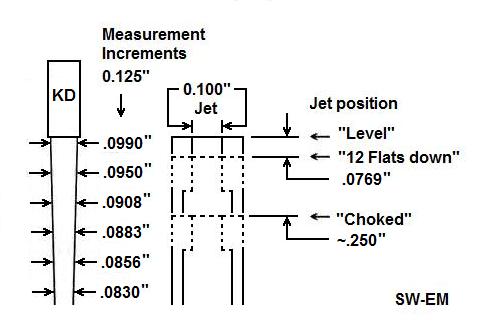

SU HS6 showing Jet

Locking Nut (11/16", 18mm), and Mixture Adjustment Nut (9/16", 15mm)

below.

Pre-Checking and Adjustment using a Centering Pin:

Prepare: Replace Metering Needle with CP, and replace normally (lightly lubed) Dashpot and Spring into Dome, then (after assuring interfacing surfaces of Dome and carb body are clean and free of debris with some carb cleaner and a rag) mount Dome Assembly normally on carb body. Snug three securing screws. Then, while supporting Dashpot with a finger or nonmetallic/non-damaging tool (like a wooden chopstick), lowering the Jet using Choke linkage, allowing Dashpot Spring to gently lower Dashpot and gently drop CP, to make either gentle contact with Jet, possibly falling into it (if it can...if these two are concentric ["Jet is centered"...great!], OR resting on side of Jet (if the two are not yet concentrically/perfectly aligned).

Check Alignment: If CP drops into Jet, repeat lifting and allowing the Dashpot to gently drop several times to verify concentricity.

Make Adjustment: If CP does not drop in or repeatedly, observe their interface with a good light source (and your close-in reading glasses!), to determine in which direction the Jet needs to move for alignment, loosen JLN just enough after lubing it with a drop of light oil (like Tri-Flow or even engine oil), to allow the slightest adjustment to be made in the desired direction, snug the JLN and recheck. Repeat this until CP drops into Jet...every time!

View of Metering Needle replaced with a

Centering Pin for the

Pre-Check and Alignment Process.

Centering Pin has fallen into a nicely aligned Jet!...actually into Jet Bearing

as Jet is down and in the chocked position...and will/should, every time when

test is repeated multiple times!

All is well, and the MN can now take its rightful place and Final Check of Alignment can be

verified with the actual MN.

If CP does not align with Jet perfectly and doesn't drop in, the Jet Bearing must be moved slightly and adjusted so that it perfectly aligns with CP, allowing it to drop in. The Jet Locking Nut (18mm/11/16") must be loosened, and a slight adjustment (we're talking in increments of thousandths here, so a fine hand is called for!) in the correct direction must be made...so the reader might ask: Just what is the correct direction? Answer: Only careful inspection of the misalignment with a good lightsource (and maybe a little luck) will tell!

Replacing Centering Pin with Metering Needle and rechecking concentricity: When Alignment looks good in the Pre-Check and adjustment, with CP installed, Final Check of Jet adjustment and position is performed with the actual Metering Needle installed once again into Dashpot.

Carefully disassemble the Dome and Dashpot assembly with CP from carb body, install the MN (correctly, with shoulder of MN flush with bottom surface of Dashpot, and MN identification preferably not at position where it will be scarred and possibly obliterated by the Setscrew!)...

Metering Needle shoulder is flush with bottom of Dashpot...checked with a

straightedge.

Final Check of Jet Alignment before declaring the Jet "Centered!", and ready for service: Dome/Dashpot Assembly can now be reassembled onto the Carb body and the check repeated for the installed NM. Normally this test will have results similar to a good alignment as when CP replaced the MN, but on the off-chance that NM does not fall nicely and repeatedly into the Jet, the reason should be determined (worse one being a bent MN, which would call for replacement of the NM!) and the adjustment procedure must be repeated until it does.

Tip: Inconsistency in results is (for instance) a sign of debris causing the Dome not to seat the same way each time it is removed...remember: Although a simple carb, SUs are precision components, so cleanliness is important!

----------------

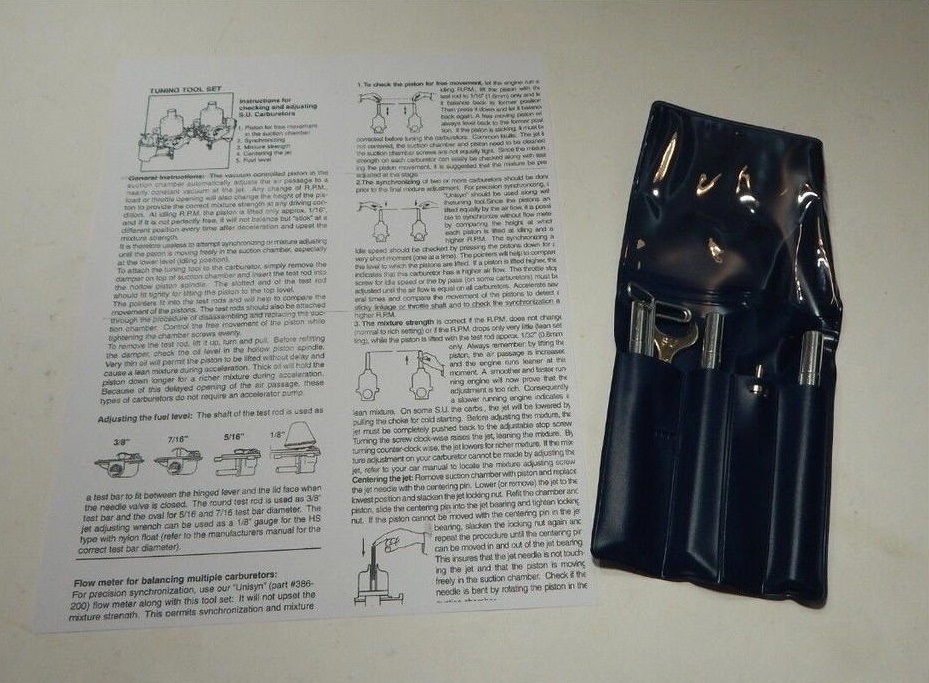

Centering Pin Detail from the little SU Tuning Tool Kit:

"SU Tuning Tool Kit" which include the Centering Pin Tool, are often available on the popular on-line auction site at a modest cost.

Screenshot from an ebay offering: Price $34.00

---------------------------

My SU expert reference Tom Bryant chimes in with his technique for Jet Centering:

I like to run anything having to do with SUs by Tom as a sanity check...here is what he thought of this write-up:

"My own practice is to simply

jump right to the final step, and that's to center the jet to the needle, in

situ. I do that by removing the adjustment nut and locking spring from the jet;

that permits the jet to move freely in the carburetor body (after the jet

bearing nut is loosened, that is). First, I test the centering, and if it's

already good, I don't even bother to do anything, other than to make sure the

jet bearing nut is gutentite, that is.

But, if I detect misalignment, then I loosen the jet bearing nut and tighten it

finger tight, then I center the jet, then I slightly tighten the bearing nut and

check the centering, if good, the I make it gutentite, and check again;

otherwise, I go back to finger tight an try again. It's usually quick and

painless, and I end up with a jet that's centered to that needle, in that jet

bearing, no CP required.

And as I indicated earlier, if I then rotate that jet one direction or the

other, it's quite common for it to be no longer centered.

BTW, when I receive a customer's carbs for rebuild, I usually remove everything

except for:

1. The lift pin, which I absolutely detest, never use myself, and usually have a

helluva time reinstalling, so I don't take it out.

2. The jet bearing and nut. I leave those in place in the hope that the jet

will be properly centered when I reassemble the carbs. Most of the time it is,

so I don't have to center it, but when it isn't centered, I proceed as described

above.

Regards,

Tom "

---------------------------

Links:

Link to full SW-EM Tech Article: SW-EM SU carburetors

------------------------------------------------------

External material sources are attributed. Otherwise, this article is Copyright © 2017-2023. Ronald Kwas. The terms Volvo and SU are used for reference only. I have no affiliation with either company other than to try to keep their products working for me, help other enthusiasts do the same, and also present my highly opinionated results of the use of their products here. The information presented comes from my own experience and carefully considered opinion, and can be used (or not!), or ridiculed and laughed at, or worshipped, at the readers discretion. As with any recipe, your results may vary, and you are, and will always be, in charge of your own knuckles, and future!

You are welcome to use the information here in good health, and for your own non-commercial purposes, but if you reprint or otherwise republish this article, you must give credit to the author or link back to the SwEm site as the source. If you donít, youíre just a lazy, scum sucking plagiarist, and the Boston Globe wants you! As always, if you can supply corrections, or additional objective information or experience, I will always consider it, and consider working it into the next revision of this article...along with likely the odd metaphor and probably wise-a** comment.