With thanks and apologies to Mr. Schwarzenegger. Another highly useful and demonstrative SwEm graphic (maybe!).

TORQUE

11/2015-2024 R. Kwas

Revisions On-Going. [Comments Added]

The Incorrect Term:

Torque Wrench

Run-In Torque

(subsection of Anti-Seize Notes)

Non-specified Torque of

Fasteners

Mechanical Fuel

Pump Fasteners

General Torque

Specifications for Fasteners

More good info...

Other Forms of Torque

----------------------------------

Background: Torque occurs (and is used) in numerous places in our cars. The driving force by which an engine works against the road, driving the tires, is more specifically called Dynamic Torque. When we turn threaded fasteners to hold assemblies together with Static Torque, applying clamping force, we often simply use judgment for how much Torque we apply, but in more important places, we'll use a Gauge to measure this force for critical fasteners...we need them tight enough, and within their usable range...but not too tight or they might break, allowing those assemblies to come apart, ruining our day.

While there are lots of theoretical explanations of torque out there...these notes will repeat some of that theoretical information in support of our practical applications, hopefully useful to the hands-on vintage Volvo mechanic.

Torque = Force x Moment

Definitions and Clarifications:

Torque = Force at a Moment (or distance from the Pivot Point). Europeans measure this in Newton/Meters (maybe because they are communists and weird)...normal Americans measure it in Foot/Pounds (Americans and tech writers in some car magazines who want to elevate themselves from the masses and further impress, might say Pound/Feet), but what's the difference? Since the resulting number is a mathematical Product, why make a big deal of the order...maybe they pour their coffee into their cream, I pour my cream into my coffee...in the end, we both drink the same thing!

Torque Wrench - is an incorrectly used term (you

might have heard it here first!) to describe a tool that measures

Torque. I do not use it! Why?...because ANY wrench is a

Torque Wrench! ...because ANY wrench applies Torque! So more correctly, a

Torque Gauge is an instrument which measures the magnitude of the

Torque applied. I use the term Torque Gauge instead of

Torque Wrench, because it more accurately describes what this tool

does, instead of perpetuating confusing and incorrect terminology...again, ANY

wrench is a torque wrench because ANY wrench applies torque...a Torque Gauge

measures it!

-------------------------

Practical Consideration: To apply a Torque to a point of turning (or Pivot), Force is applied at some distance from that Pivot (or Moment). Since it can be taken from the basic formula, that this resultant is a Product of Force and Moment, the two have an inverse relationship. This means that in order to get some fixed amount of Torque, we can make one bigger if we made the other smaller, and still get the same resulting Torque. In other words, to apply a given Torque, the closer Force is applied to Pivot (shorter Moment), the more Force must be applied. Conversely, the further Force is applied from Pivot point (longer Moment), the less Force may be applied.

Here is a graphic to demonstrate this. Notice points where Force is applied below: A - for Arnold Force point, B, and C - for normal mechanics, and M - for Mosquito Force point!

With thanks and apologies to Mr. Schwarzenegger. Another highly useful and

demonstrative SwEm graphic (maybe!).

Conversely, if it's not so important to apply a constant measured Torque, but rather as much force as possible to help with removal of a stubborn fastener, we can increase the Torque applied by our limited "puny human" Force by applying it to the MFP...it's just simple math!

Source:

https://youtu.be/Bnh2AplyKi4?t=23s

In extreme cases, we can further increase it to Impact Torque, by employing a hammer on a wrench (but please not on a Torque Gauge). A good example of this on a vintage Volvo is the Brakedrum removal with a puller. Link: http://www.sw-em.com/Brake_Drum_Notes.htm#Removing_a_Difficult_One To exert the Mega-pulling force required we first install puller, then apply torque to some threaded part of the puller, which is translated to pulling force, finally we might need to apply impact Torque to make the last bit of pulling force necessary...thankfully, we don't need to measure this Torque...only apply it...I expect it would be in the thousands of Ft/Lbs!

Another case of where serious Torque is needed, is when using Trick 17 to remove seized bolts.

---------------------

Common Styles of Torque Gauges:

Beam Type Torque Gauges have been around for a long time. Honest and without magic, they are simple and (almost) fool proof in that these wrenches are based on them bending of a Beam which makes up the tool. Everything is right there to see, so its tough to mess up...even IF the Beam had somehow taken a minor set in one direction and pointer was off zero a bit, I would simply add this difference to the target Torque and use the tool with confidence!

These (and ALL) Torque Gauges can be used with an extension (more on this below) at the socket (not handle!) end, to bring the wrench up and away from the work piece, but their socket drive is fixed at one angle and typically they do not ratchet, so this might present an access difficulty in some cases (a twelve point socket may help by giving more angular opportunities than a six point socket in that case).

A common Beam Type Torque Gauge by Craftsman. Torque is directly

read from scale. Notice the

HANDLE PIVOT, central to the operator handle

(and more importantly, at a very specific distance [Moment] from the tool pivot). This assures

that operator applied force is at a precise and unvarying distance

(Moment) from the Pivot, an

important factor in assuring accuracy and repeatability!

-------------------

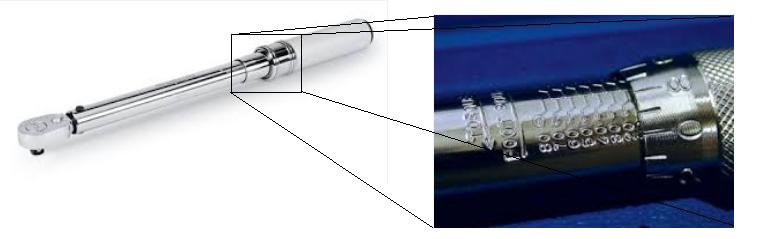

Click Type Torque Wrench...this is a

doubly wrong and a poor name because of (1.) ...the nomenclature issue

mentioned above. At the very least, it would be a Click Type Torque Gauge

...but wait... (2.) ...in fact, this tool doesn't even measure and

indicate Torque...it LIMITS Torque to some preset value! That is why I

will refer to this tool as a Click Type Torque Limiting Wrench.

(Sorry for the mouthful, but rather a mouthful and correct, than quick and

wrong!) Does the reader get the feeling that as many inconsistencies in

terminology there are, it's easy for misunderstandings and mistakes to occur?

Click Type Torque Limiting Wrenches have a torque limiting feature in that they click, as well as giving the operator a tactile feedback as an internal spring loaded mechanism releases from a previous setting, preventing operator from applying more Torque. They are nice in that once set, they don't require operator judgment (or even that operator watch them as they use them). This is why they are preferred in a production setting where speed of the work process is important. Also, employers want to take any operator judgment out of the process, and hire cheap labor...a different issue!

The down-side here is that one must trust this tool blindly, presuming it to be accurate (and I feel the same way about this as I do about blindly following a GPS!...so I don't!)...how does one really know if they are accurate and calibrated (or if they may have been dropped and should be checked before being trusted)? Luckily, checking accuracy of these tools periodically to build confidence is fairly simple and can also be performed in the home shop! See: Reference Information: Checking Calibration

A Click Type Torque Limiting Wrench. Expanded is the setting area

where operator sets Torque at which to limit.

---------------------------

Other Torque Gauge Variations. Dial and digitally indicating Torque Gauges are also available. These are (if calibrated and to be trusted, presumably more accurate. I might elaborate further on these in the future. For now, coverage of the Beam Type and Click/Limiting types should help the reader to understand the simple principles...after that, it's all easy!

--------------------------------------------

Beam Type Torque Gauge:

More useful information from: http://www.garagejournal.com/forum/showthread.php?t=28685

Note the useful Torque-chart!

-------------------------------

Checking Calibration of a Beam Type Torque Gauge: Good info: http://home.jtan.com/~joe/KIAT/kiat_3.htm also source of graphic.

OR...one could secure wrench drive point in a vice (with Beam horizontal!),

measure the Moment (distance between Drive Point and Force Pivot...if this is

not one foot, an adjustment calculation [see Note 1] must be made),

hang a known Mass (in lbs.) from the Force Point and observe indicated Torque.

Indicated Torque should be consistent with expected!

If it was my graphic, I would have shown it with a Mass hanging down from the Force (Pivot) point. Beam would then obviously be bending downward.

Note 1. If Beam length of a particular Torque Gauge being tested is one foot...Great!...Torque indicated would be exactly that which is hung on Force Pivot point. Hanging 20lbs. should indicate 20Ft/Lbs. But more realistically, and commonly, Beam length longer For instance 18inches...this is a 1.5 relationship to a foot...so this becomes the Correction Factor. Hanging 20Lbs on that Gauge will indicate 30Ft/Lbs. ...refer back to Arnold and the mosquito!

Torque (Indicated) = Test Mass x Beam Length x Correction Factor

---------------------

Improvised Torque Gauge:

Since we understand the simple math of Force applied at a Moment, there is nothing keeping us from improvising such an arrangement and knowing/calculating fairly precisely (within the accuracy of out luggage scale anyway!), what the applied Torque is! I found this at: https://www.engineeringtoolbox.com/torque-wrench-luggage-scale-d_1909.html [...my correction added!]

---------------------

Additional:

Checking Calibration of Click Type Torque Limiting Wrench: [I also ran across this procedure while surfing]. Set your own weight on Wrench. Secure Wrench drive into a bench-vice (which is solidly mounted, and which will allow you to apply that amount of force down onto wrench). If wrench is accurate, it should click just as you feet become unweighted. Done!

Well...not really...this is oversimplified! After thinking about it, this technique sounds almost useful, but what if you weigh more than maximum setting of wrench...and what if wrench length is something other than one foot? ...or what if you wish to check wrench accuracy down to Torque values in the more typical range of where it will be used, not at 300FtLbs?

I checked and found that my Click Type Torque Limiting Wrench goes up to 200Ft/Lbs, and that it's 20" long, so my weight would easily apply over that torque (not that I'm a XXXL or anything, but just like with the Beam Type Torque Gauge, an adjustment calculation and Correction Factor are also necessary here). So in addition to coming up with, and applying the Correction Factor, I would change that procedure by hanging a known test-weight on the tool handle...unless you have a short guy of known weight available to help!

Image source: Also

http://home.jtan.com/~joe/KIAT/kiat_3.htm

--------------------------------------------

Links:

Discussion Thread: Torque wrenches + extensions = reading corrections? http://forums.turbobricks.com/showthread.php?t=219974

I do agree with Mr. Allen that Beam Type Torque Gauges are more accurate in part because they are simpler(!), and although he tries to establish his high qualification ("...I was managing an aircraft accessory shop..."), I still have to disagree with his assertion that using an extension would give a less-than-accurate torque indication ("...false readings due to the twist of the extension"). This is just not true...an extension may very well twist, but that doesn't mean it affects the reading! Remember, when torqueing fasteners, we are dealing with Static Torque!

The condition is analogous to having a non-solid (flexing material) in-line with the force...like weighing yourself on a scale but putting a piece of foam on the scale before stepping on it ...the flexible material may have deformed while things were dynamic (right after you stepped on the foam and scale and it was moving to its' new position), but once everything is static and the material is deformed, and remains that way (Equilibrium is reached!), it does not add or subtract ANYTHING from the force. Using an extension with a Torque Gauge does NOT decrease its' accuracy!

...it's called getting distracted (and fooled) by something which doesn't matter (or maybe not having paid attention in Physics Class)!

--------------------------------------------

Non-specified Torque of Fasteners:

Mechanical Fuel Pump Fasteners:

My response to a Faceplant

![]() thread asking

about torque on fasteners which is not specified in the manuals...specifically,

the mechanical Fuel Pump bolts, which pass through the

[brittle] bakelite spacer and into

the engine block.:

thread asking

about torque on fasteners which is not specified in the manuals...specifically,

the mechanical Fuel Pump bolts, which pass through the

[brittle] bakelite spacer and into

the engine block.:

"Torque is not specified for

these bolts** as it is not critical...use the judgment which comes from years of

wrenching (including what is learned, when leaks or self-loosening occur when

fasteners are not tight enough, or having broken some off, when they are too

tight!)...what is critical here is not to unevenly or over-torque them, which

will fracture the brittle spacer, and cause oil leakage.

** Fastening torque for MANY bolts on cars is not

specified, because it is not critical, and mechanics develop a "feel" and

judgment for this after a while...in the case of the FuPu mount, it is not metal

on metal, but a metal/Bakelite/metal sandwich in compression, so a bit LESS

torque should be used than typical...when

there is not a brittle material in line with the clamping force"

Note also that when torque is specified, it will take into account an unusual situation, such as the fasteners compressing stack of material other than metal, for example, as discussed here, the Fuel Pump securing fasteners which also pass through the brittle Bakelite spacer. In this case, the torque must be reduced further, and special care must be observed when securing these, to prevent fracturing the Spacer.

Another Response to a Faceplant

![]() thread asking

about torque on fasteners which is not specified in the manuals:

thread asking

about torque on fasteners which is not specified in the manuals:

"...[no] Torque is specified for these [important, but non-critical] fasteners, so it is another situation of using judgment when operating the wrench! ...OR: Keep tightening until it gets really loose, then back off a quarter turn...not! "

--------------------------------------------

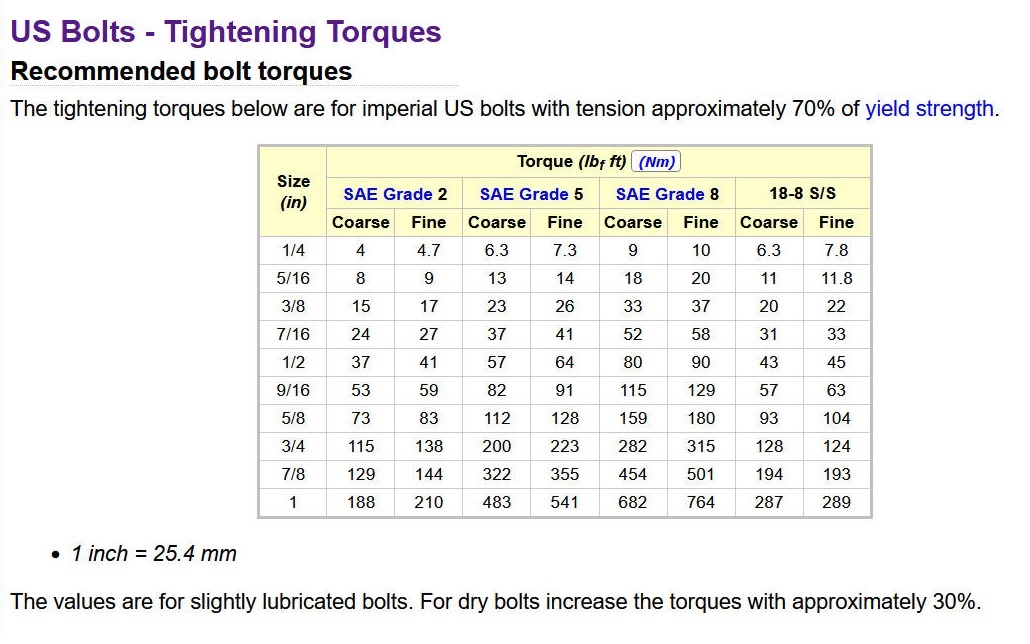

General Torque Specifications for Fasteners:

For fasteners where no Torque is specified, or if an occasional mechanic is unsure of their strength, and still growing their experience-base, so would prefer to work to a specified number, the charts below gives recommended tightening Torques for typical fastener sizes. Notice the number given vary by bolt grade, and are to 70% of yield strength, so with a good margin to the breaking point! [Although I do find it somewhat unlikely that anyone owning a Torque Gauge would not be in a position to have developed the "feeling, judgment and confidence" of not needing one for general fasteners...most mechanics engaged enough to own a Torque Gauge have developed the judgment for non-critical fasteners, and only use the Torque Gauge for when a fastening Torque is specified.]

Source: https://www.engineeringtoolbox.com/us-bolts-torques-d_2055.html

Notice also the K-Factor of 30%. This is given as 10-15% for Anti-Seize

lubricated fasteners, so one can see a fair variation.

Link to: K-Factor under Anti-Seize Notes

Just in case you're interested in Metric fasteners, or working on a post '75 Volvo:

Source: https://www.engineeringtoolbox.com/metric-bolts-maximum-torque-d_2054.html

And here is a handy chart comparing the two, including the Fastener-head markings:

Fastener Application Information:

US Grade 5 (three lines on

head, Tensile: 120,00PSI) = approx. metric property class 8.8 Regular (nothin' fancy...quality, general

purpose fasteners).

US Grade 8 (six lines on head, Tensile: 150,00PSI) = approx. metric property class 10.9

Better (the good stuff...for your Brakes!).

US Grade 2 (no lines on head, Tensile: 60,00PSI...maybe!) = Junk low carbon bolts...china's finest!...good for holding together lawn furniture!...well...not really, because the only way you could get this trash metal to rust any faster than leaving it in the back yard is by dropping them in the ocean! ...never to be used on your Volvo! ...but nice because you can buy them long, and easily cut them to length (with a butter knife).

ASTM-A574 (Socket Head Capscrew, even better than grade 8!) As specified and used as the important Pivot Bolt in the SW-EM Alt Kit.

--------------------------------------------

More good info in the form of a YT video:

If the reader hasn't had enough on Torque, I ran across this very good YT video in my travels...where they test several click-type Torque Gauges, and techniques and accessories to compare and in some cases dispel misinformation and myths out there. They do call them Torque Wrenches [I'll get over it!], but I'm happy to see that they confirm the K-factor for lubricated threads, and also irrelevance to torque setting, of using a socket extension!

https://www.youtube.com/watch?v=-hSmtLVESSM

Using solid science and a little math to confirm that T = Force X Moment thing!

-----------------------------------

--------------------------------------------

Finally:

Another form of Torque can occur, when on an otherwise open two lane highway, some SOB in the left lane paces the truck in the right lane at 50mph, effectively creating a rolling roadblock.

State Law (in Connecticut, and left-Hand Drive countries that is):

---------------------------------

External material sources are attributed. Otherwise, this article is Copyright © 2015-2024. Ronald Kwas. The terms Volvo and Craftsman are used for reference only. I have no affiliation with either of these companies other than to try to keep their products working for me, help other enthusiasts do the same, and also present my highly opinionated results of the use of their products here. The information presented comes from my own experience and carefully considered opinion, and can be used (or not!), or ridiculed and laughed at, or worshipped, at the readers discretion! As with any recipe, your results may vary, and you are, and will always be, in charge of your own knuckles!

You are welcome to use the information here in good health, and for your own non-commercial purposes, but if you reprint or otherwise republish this article, you must give credit to the author or link back to the SwEm site as the source. If you donít, youíre just a lazy, scum sucking plagiarist, and the Boston Globe wants you! As always, if you can supply corrections, or additional objective information or experience, I will always consider it, and consider working it into the next revision of this article...along with possibly a unique metaphor and probably wise-a** comment.