Vintage Volvo 6V to 12V Conversion

originally posted 07/2002 R. Kwas (Updates, Comments, and additional material added continuously.)

AC Delco Alternator installed on a

B16

Dropping Resistors

Reference and

Related Info:

Comments about 6V electrical

systems.

6V PV Electrical

System voltage measurements

6V to 12V Converters

544 Intermittent Wiper (after

6-12V Conversion) Notes by SW-EM Guest Contributor

Richard Allen

Dropping Resistor for 12V operation of Fuel Gauge

6V Delco Alternator

-------------------------

I totally understand there is a certain need to keep your vintage Volvo as it was designed and delivered from the factory. There are value of originality issues and there's always the argument that if Volvo originally designed it that way, it must have been fine...and this is true...6V automotive electrical systems were typical and state of the technological art in their era. However, if we intend to use the vehicle now, decades on, as a "daily driver", when nothing less than absolute reliability will do (including starting, and white headlights, and vigorous windshield wipers), some owners may want consider an upgrade to a 12 Volt electrical system. The conversion work involved is significant, but not so much as to be overwhelming.

Link to Comments about 6V electrical systems.

The practical information here is presented for the benefit of those doing this upgrade, or just those considering it, and is based on an actual conversion performed by Bill Matuscak in Wisconsin, under my guidance (strictly via e-mail and pix...). Taken one item at a time, the article will cover background information and actual steps required, with actual Bill's actual results and notes [in yellow] here and there. As usual, I stand by the info presented here, and will always try to help with questions, but in the end, YOU are the master of YOUR destiny, hence the following disclaimer.

The information here has been compiled and checked with the utmost care, but is strictly a guide to be used in conjunction with normal, cautious shop practice. I cannot be responsible for your specific actions, work safely!

Suggested prerequisite reading, if you need to build up your confidence in tearing into your automotive electrics: An automotive electrical Primer tech article

General: The upgrade will be accomplished by one of the two following manners, with the first being preferred wherever possible:

Circuit modification of non-replaced items. For those items which for cannot be replaced and must therefore remain, Ohms Law, and some mathematical Kung-Fu will be used, to design dropping resistors (DRs) which will allow the existing 6V loads to operate safely on the new 12V system.

Replace Items list:

All lamps...headlights, marker/signal-lights, parking lights, instrument lights, interior and courtesy lights must be replaced with 12V lamps of equal Wattage rating. Lamps rated at 6V do not take kindly to a doubling of the voltage they are subjected to, and would burn out in short order. These are all available with similar lamp bases and mounting so this should be straightforward. It would be a good idea to make right any questionable wiring, and also clean up the lamp socket connections with a tiny wire brush to get rid of any green stuff which may have grown over the years, and finally install the new lamps with a dab of anti-corrosive paste. This will ensure a clean, and trouble-free electrical connection for probably the next forty years. Flasher element? (see below!).

Ignition system. Replace ignition switch / armored cable / coil assembly with a 12V unit from a later 544 or 122. PN? Components of the distributor do not require replacement.

Charging and Energy Storage System. Replace Generator and Regulator with a modern internally regulated Delco alternator mounted on a custom bracket. A SwEm upgrade kit is in the works! * Replace battery (see below!), with a 12V type.

AC Delco Alternator installed on a B16: (previously 6V PV444) . Visible is the slight "S" bend required in belt tensioning bar to accommodate differences in o.e. generator and upgrade alternator housings and mountings to keep Fanbelt in one plane.

Pictures credits to Bill Matuscak.

Control Devices. Any 6V relays present, including starter solenoid,

and M31 overdrive solenoid (rare as they may be), see also details below).

Since the original fuses were rated for current drawn in 6V service, they will need to be replaced with fuses of half their current rating. Obviously, if we have added or changed loads on a particular circuit, this needs to be taken into account also, in determining a new current rating of the replacement fuses.

Note: It is not necessary to replace any wiring as a part of the conversion, but it is a great time to check, clean, refurbish, and prep with Anti-Corrosive Zinc Paste, all connections on the vehicle which you will be working with as part of the conversion work (preventative maintenance is always more fun than post-failure maintenance).

Non-replace Items list:

Heater blower motor. A DR (see below) may be calculated and installed.

Wiper motor. A DR (see below) may be calculated and installed.

Pictures of bench tests of 12V fuel gauge, as used in Volvo applications. For more info on the balanced magnetic "Drehspulinstrument" Moving Coil Indicator which is the heart of the fuel gauge, see also: Drehspulinstrument Data originally posted on the German Volvoniacs Forum.

|

|

|

Fuel gauge from a 6V1961 PV544 fuel gauge.

Unfortunately the gauge face and pointer were lost forever...but it clearly also uses the VDO supplied balanced magnetic "Drehspulinstrument", but NO internal dropping resistor.

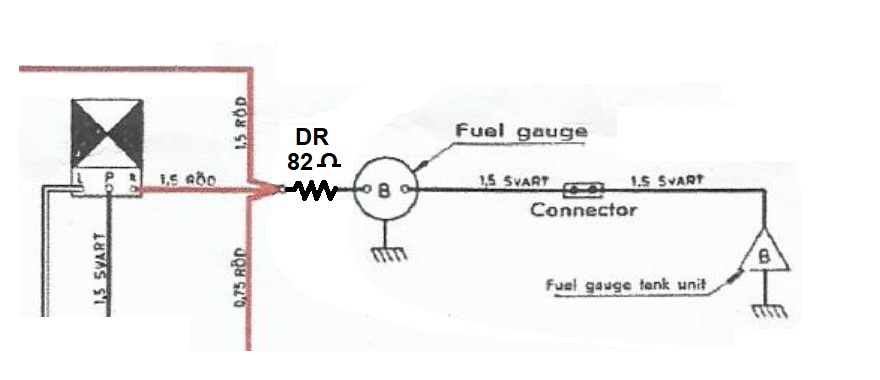

Physical comparison, passive checks and power up performance tests confirm, that the VDO magnetic indicator movement used in the 6V and 12V instruments are the same, with the only difference being the addition of the 82 Ohm resistor in series with the power input lead in the 12V version. This is great news because it means that when you upgrade your originally 6V 444/544 vehicle, you can effectively and simply add this resistance externally to the instrument panel and be done!... removal and modification of the fragile fuel gauge is not even required! [Could this be another reason to "love your Volvo"?] ...but don't forget to replace the indicator and lighting lamps of the Instrument Panel with 12V rated lamps!

[See also: Reference and Related Info: Dropping Resistor for 12V operation of Fuel Gauge. ]

Radio. A DR (see below) may be calculated and installed, so that an o.e. radio can be left installed in the radio slot and used...of course, after the upgrade, you will have enough power on-board to also mount a slightly hidden, high-power, CD, cassette, tuner, super wowee/whiz-bang, impress-the-heck-out-of-Alice-Poobats-on-a-Saturday-night modern sound system!

Starter (solenoid only needs to be replaced, or a DR may be required, see below!). Thanks to the high degree of safety margin in the originally fitted Bosch starter **, the fact that starters are usually only operated for a short time, and the additional fact, that the voltage actually drops significantly while drawing the (high) starting current, it is totally acceptable to operate the 6V starter on 12V (...and we wouldn't by any means be the first to do exactly that). With a higher voltage applied, the starter will run like gangbusters, so starting will typically be significantly improved. There will also be more heat generated (have you heard of the saying: "Burning the candle twice as bright for half as long"?), so cranking for extended periods should be avoided. If cranking for long periods is called for, a cooling off time between attempts is recommended. The solenoid on the other hand doesn't have the ability to withstand a doubling of the operating voltage for too long...and so it should be replaced with a later 12V type. I believe these are physically compatible.

[ Confirmation and details from Bill ... apparently, they are NOT physically compatible... so a DR solution may be necessary (installed in the solenoid power lead coming from the IGN switch)... this will be based on temperature tests which still need to be performed! Results from Bill are in: Temperature rise is a mere 12 degree F above ambient, after 15 seconds of cranking (ignition was disabled), so a DR is NOT required! ]

OD Solenoid A somewhat rare factory option was the M31 overdrive transmission. The control solenoid of this OD needs to also be carefully considered, but the solution here is further complicated by the fact that the solenoid is (likely) a two coil type similar to what was used in the 12V service. Both "pulling coil" and "holding coil" are activated upon application of power, and as the armature reaches it's travel limit, in addition to activating the OD, it also opens a switch internal to the solenoid, which cuts off power to the "pulling coil". In this manner solenoid power consumption and heating are limited...which is good, but it significantly complicates a DR solution...I will post info and results, when I can investigate and come up with a satisfactory 6V solenoid solution.

---------------------------------------

Dropping Resistors (DRs): A very simple solution to operating 6V devices on a 12V source is to calculate and install a DR to drop 6V. This will leave another 6V to operate the load. A DR is wired in series, see diagram (that is, ALL current which will flow through the load must also flow through it, so we will use the electrical fact that current passing through a resistance will result in a calculatable voltage across that resistance to drop the excess 6 volts. DRs are a simple, but pretty inefficient solution (they are quite reliable because they are in-fact, a brute force solution, so they waste heat - and a fair amount of it!). This also continuously keeps a higher load on the source of power in the vehicle, the alternator...luckily an upgrade alternator can easily take it! For this reason, DRs are not the most elegant solution, but once designed correctly and installed so that the heat they produce can be dissipated safely, they can just about be considered a maintenance-free, "bullet proof" solution...and maintenance-free, and "bullet proof" is very good!

Simplified DR wiring diagram. Notice that the

intentional Voltage Drop

occurs only when associated switch is closed and Load Current flows!

Calculating DRs: First, the actual current (I) drawn by a given load must be measured (beware, for motors, this varies with the mechanical load on the motor...a heavily loaded motor - like a wiper moving snow - can draw significantly more current than a lightly loaded one just doing easy laps).

Next, we use Ohms law to calculate R, and the power dissipated P, so that we can size the DR accordingly.

Example: I is measured at 3 Amps. We know V to be 6 Volts (the amount we need the DR to drop).

...here comes the mathematical Kung-Fu:

Resistance = R = V / I = 6 / 3 =2 Ω (Ohms)

Power = P = V X I = 6 X 3 = 18 Watts

Another more realistic example (I am told, that the single speed, PV444 6V wiper motor draws 5 Amps).

...more Kung-Fu:

Resistance = R = V / I = 6 / 5 = 1.2 Ω (Ohms)

Power = P = V X I = 6 X 5 = 30 Watts (a significant amount of heat!)

Where does one get DRs? Low resistance, high wattage resistors are not usually items one can pop down to the local electronic supplier and pick up. They are also quite expensive, so I wouldn't want to buy them new! A good source is the surplus industrial / electronic field, but when obtained this way, we may not get the exact value we have calculated. For this reason we may need to combine (in series and/or parallel), more than one resistor in order to obtain a calculated DR resistance value. Also, it is important to get the type which are packaged so that they have a provision for mounting on a surface. This allows them to transfer some of that heat more easily than if they were "hanging in the air".

For instance: We have just calculated that we need 1.2Ω, but I only happen to have a quantity of the really nice 2Ω Dale power resistors seen in the picture following. The solution: I would use two of the 2Ω resistors in parallel to give 1Ω, this is very close to the design value of 1.2Ω, and in fact would actually give the motor a slightly elevated operating voltage (no problem there...desirable maybe even!), so that is what I would recommend (...and here is additional good news: The fact that the DRs are in parallel also spreads the heat amongst them, so individually, they will not get as hot. [The actual total heat energy produced will be the same though...physics is funny like that!]).

An Example of a High Power Resistor suitable for use as a DR.

A 2Ω, 50Watt power resistor (encased in a nice gold anodized metal

case) as used in the electronic industry, manufactured by Dale. Mounted on

the sheet-metal somewhere, this one would be just the right thing for a load

drawing 3 Amps. Special thanks to my "short guy" for the temporary use of

a Lego block (5/8" X 1 1/4") as a size reference.

---------------------------------------

Thermal considerations: The heat produced by the DRs must be safely removed, spread out, or dissipated. If this is not done, the DR will keep increasing in temperature, possibly destroying itself or damaging or even igniting anything flammable which might come in contact with it. Mounting the DR to a "heat-sink" is the solution. A "heat-sink" is any large mass which will allow the heat to spread, with a large surface area to allow the surrounding air to be warmed, thereby taking away this thermal energy...sound familiar?...the vehicle radiator might also be called a heat sink (but it is more accurately a liquid-to-air heat exchanger). The sheet-metal of the vehicle fits the bill well, and in order to most effectively conduct heat from the DRs to the sheet-metal (even a tiny air-gap is a poor thermal conductor), a thin film of Thermal Interface Material (TIM) *** (also used in the electronics field) should be used. A good rule of thumb is: If its warm (even very warm), but you can touch it (if just momentarily), it will operate fine that way for just-about ever!

DRs mounted on an Aluminum plate and mounted in the

former Voltage Regulator location on Bill's 444 (of course they could be hidden

too). Notice also the retired 6V battery in the background. (Pictures credits to Bill Matuscak.)

Practical considerations: When wiring DRs, wiring suitable for the expected currents should be used. The insulation should be rated for 600V (huh?)...that seems like a lot when it will be seeing a mere 6 or 12V, but a car must certainly be considered a "high vibration environment", so the double insulation thickness (from the standard 300V) is definitely justifiable!

Specifics:

Standard fan belt can be used with alt upgrade. [from Bill: NAPA part number 25-7350. The dimensions of the belt are 25/64" wide and 35 5/8" long. It works great and runs straight... Gates PN: 7350]

Heater blower motor. DR = [0.6Ω 150W, (3 2Ω resistors in parallel). Bill reports a 90 degree F rise above ambient after 15 minutes of operation.

Wiper motor. DR = [6.0Ω 150W, (3 2Ω resistors in series). Bill reports a 40 degree F rise above ambient after 15 minutes of operation.

Fuel gauge. Install an 82 Ohm, 1 Watt resistor in series with gauge power lead. See above! See also below: Dropping Resistor for 12V operation of Fuel Gauge

Radio. DR = TBD

Starter Solenoid. DR = None required. See above!

Wrap-up:

Bill's post conversion thoughts...does he notice a difference?... better, worse?....bottom line - was it worth the effort, time, expense?

Bill Matuscak writes: "Was the change worth it? In two words HELL YES!! Mechanical advantages: Better spark at the plugs, instant starting, ability to add accessories such as driving/fog lights, radio, etc. and easily replaced parts (alt, coil, fan belt) if something fails on a trip. Safety advantages: MUCH better lighting at night and brighter turn signals and brake lights by day. I went on that 150 mile color tour with my car club. It was sunny and about 55 degrees. A fellow with a 34 Ford street rod followed me. At our lunch stop I asked if he could see my brake lights ok. He said brake lights and turn signals showed up fine. I took the car out one night to adjust the headlights. What a joy to actually see things on the road at night! This 12v conversion makes a real car out of the 444 and now it can be driven safely both day and night, which increases the usefulness of the machine. And hey, driving these things is what it's all about, right?"

[see also his SwEm guestbook entry. Thanks Bill!]

See also: Mar 2009: BIll M. Long-term Feedback

UPDATE 2018: I have recently spoken to Bill M. as I had some questions regarding the Wiper Motor and Assembly...apparently he moved the car along, as he has a number of vintage vehicles (not necessarily Volvos) but the car, including his electrical conversion work was still performing satisfactorily when he sold it. I have not (yet) heard from the new and current owner.

Comments and questions on this article, your own experiences doing a 6 to12V conversion are especially welcome and appreciated. Ron

---------------------------------------------------------------------------------------------------------------------------------------------------------

Available, to help with your 6 to 12V conversion project:

A limited number of industrial strength Dale 2Ω, 50Watt power resistors as see above.

A limited number of industrial strength Ohmite 10Ω, 100Watt variable power resistors (rheostat). Use one of these monsters to verify your calculations, double check and even make adjustments to the dropped voltage before permanently deciding on, and installing DRs.

Please e-mail for details.

Draft for using rheostat to help getting the right DR value:

1. Using an accurate current meter wired in series with one load at a time, measure what the load draws for current.

2. Using the formula R = 6/ I (measured current), calculate DR.

3. Using Ohmmeter function of Multimeter, set variable resistor (rheostat) to calculated DR value.

4. Wire rheostat into circuit in series with supply 12V.

5. With a fully charged 12V battery as the power source, operate ONLY load with voltage dropping rheostat (do NOT turn on 12V power to ANY loads which do not have a DR in place), and measure Load voltage (with Multimeter set to Volts, see "Simplified DR wiring diagram" in article). Note: Voltage will indicate 12 before load is turned on and DR drops voltage...this is normal and to be expected. Voltage will drop to around 6V as soon as power is turned ON to load, and circuit current starts to flow, if calculations et al are correct. You can now vary the rheostat SLIGHTLY to raise or lower the voltage operating the load. Remember: If you adjust rheostat value to 0Ohms the load will be subjected to the full12V. Baaaad! Monitor heat generated by rheostat.

6. Remember, motors draw more current under high load, therefore the DR would drop more voltage across, leaving less for the load. It is therefore advisable to start with around 8V on the wiper motor which may see heavy loading due to for instance snow. This is not an issue for other loads.

7. Measure the resistance of rheostat which gave best load operation, and permanently install fixed DRs of this value in series with load (on heat-sink using heat-sink grease). Verify operation, load voltage, and DR heat generation once again.

If you are not clear on ANY of these instructions, contact me BEFORE applying power and blowing something up!

---------------------------------------

Comments and Notes from owners with Firsthand Experience:

Flasher: Buy an

electronic one. Despite my deeper inner feeling against solid state stuff in my

Duett, these things are cheap and genial. They work from 6 to 24 Volt.

Battery tray: The Duett/Buckel 6 Volt battery tray is too narrow for the

normal 12 Volt 60 Amp batteries. But some looking around showed me that you can

get batteries from the better brands like Varta, that have enough capacity and

starting power, but are narrow enough to fit into the 6 V tray. You can forget

about those nostalgic black rubber batteries with open cell poles, unless you

install the battery tray from one of the newer 544's. Not expensive, but a lot

of work. Greetings, Kees

---------------------------------------

References, Notes and Links:

* Link to SwEm kits, B4, B16 alt upgrade kit. [In progress, not yet complete, please e-mail for details if you're interested!]

** Talk about Bosch starter margin of safety and reliability...here's a story I recall (don't quote me on details, but I think you'll appreciate the point. Link: Bosch Starter Story ). In 1988 or 89, Jaguar won the 24Hour of LeMans race again in many years...aided by a problem of the leading Porsche team!...because of a combination of fuel consumption calculation errors and communication difficulties on the part of the dominating Porsche team, the driver tried to complete more lap than he should have...and RAN OUT OF FUEL!!!... halfway through the lap...what did he do?...he put the car in gear, and drove it to the pits using JUST THE BOSCH STARTER and battery power!...and made it...they fueled the car, and even though they had to "drive the wheels off the racecar" for the rest of the race in order to catch back up, they finished in second place, no laps down! Now that's what I call margin of safety, and reliability for a starter!

*** Thermal Interface

Materials (TIMs). Titanium Oxide containing silicon grease is commonly

referred to as Heat sink grease. A thermally conductive paste should be

worked with carefully as it can make an awful (white) mess on whatever it gets,

but a slight film improves the transfer of heat for the DRs to the mounting

surface significantly.

See also:

http://www.peltier-info.com/tims.html

-------------------------------------------

Comments about 6V electrical system:

In its day, 6V vehicular electrical systems were quite common and the "State of the Art". As time, experience and technology moved on, it was realized that with an increase in system voltage to 12, currents and therefore conductor gauge could be decreased, for a cost saving, always an important product driver! There is nothing inherently wrong with a 6V electrical system! Just be aware that when starting out with 6V, it is even more critical that none of that voltage be lost, a tenth at a time, through poor connections on the way from source to load. Clean and tight connections are even more important!!

6V PV Electrical System voltage measurements under various operating conditions.

From: https://www.youtube.com/watch?v=PzDj49BF4V0

-------------------------------------------

For an owner who preferred to keep his 6V PV444 at that voltage, but who

couldn't locate a 6V Windshield Washer Pump, and who also wanted to operate his

GPS from on-board power. He installed a modestly priced converter module to power each. Source:

https://www.volvoforums.org.uk/showthread.php?t=279066

Two 6-12V electronic converter modules power 12V equipment in a 6V PV444.

These switchmode modules operate at a high efficiency point, and are modestly priced. The modules used were procured from ebay...I have no experience with their reliability, and fusing the input power is of course recommended.

6V to 12V Converter with enough output current rating (2A) for many modest output power radios.

-------------------------------------------

Link to: 544 Intermittent Wiper (after 6-12V Conversion) Notes by SW-EM Guest Contributor Richard Allen

-------------------------------------------

Dropping Resistor for 12V operation of Fuel Gauge:

Posted to thread: https://www.volvoforums.org.uk/showthread.php?t=300402

As shown here, since the Fuel Gauge is used as a common tie point for several

Ignition Power wires, when adding the recommended 82Ohm Dropping Resistor

to the supply line for gauge and not locating it inside gauge as shown in

pictures of Fuel Gauge above, all wires must be

removed from gage terminal, remain tied together, to supply high side of DR for

Gauge, and to continue to supply all other loads without the DR in series.

Resistor then is connected to the Gauge supply terminal to supply (only) the Fuel

Gauge. This means not having to extract and work inside Fuel Gauge.

-------------------------------------------

Further reading from: http://vintagecars.about.com/gi/dynamic/offsite.htm?site=http://www.yesterdaystractors.com/articles/artint8.htm

If your tractor is a working tractor, there is little reason not to convert beyond the cost. A 12 volt system is a bolt-on cure that masks the many ailments of hard starting machines without the time and expense of teardown and rebuild. The original 6-volt system will suffice if the tractor is well maintained with optimum tuning, good compression, correct gas flow, and minimal losses in the wiring. In the real world, it is difficult to invest the time necessary to keep up on all these issues and 12-volt conversion becomes inviting. Still, the most compelling reason to convert to 12-volt is that your existing 6-volt system has serious problems and requires replacement anyway. When this occurs, it may actually be easier and less expensive to convert. Locating original components may be very difficult and time-consuming.

On the other hand, if your tractor is rare or you're are restoring it for originality or show, it would be a cardinal sin to update the electrics to 1990's standards. In this case, you will have to take the time and expense to make the 6-volt system work as it was intended. Normally this is not a problem because the your restoration process will need to cover all the issues that make the original system work well anyway.

What do I replace (or what do I reuse)?

If it seems that conversion is the right thing for you, several things will need replacement. Due to some oddball items used on a few machines, it is hard to be definitive on this but for the most part the following list shows the items that will have to go on most tractors:

Generator - Since the generator is not made to produce 12-volts, it cannot be modified to charge a 12-volt battery. Remember to save your old generator, someday you may want to restore your tractor or if you sell it, someone else may want to. When you look for your new replacement alternator, be sure to match the pulleys as closely as you can. The issues are the width of the belt, depth of the belt (determined by its v-shaped profile), and the diameter of the pulley.

Battery - Here is where you get to go buy that new Die-hard. You will have to match the size and shape of the existing battery to avoid changes to your battery box. Since you will have to exchange your old battery, take it in and accurately compare the profiles; height, width, and length.

Now the best part, what do you get to keep. The following items can be reused, but be sure to understand the limitations.

Good additional info at:

http://www.oldihc.org/Faq/6-12%20conversion.htm

Good battery information : http://www.windsun.com/Batteries/Battery_FAQ.htm

42V is coming! http://www.oldihc.org/Faq/6-12%20conversion.htm

Link to: http://www.geneseeproducts.com/glinks.htm [Tractor info, but where do you think a B18 came from originally?]

-------------------------------------------

Link to separate Tech Article: Alternator in 6V Vehicles (...it's possible!)

--------------------------------------------

External material sources are attributed. Otherwise, this article is Copyright © 2002-2023. Ronald Kwas. The terms Volvo, Bosch, and Delco are used for reference only. I have no affiliation with any of these companies other than to try to keep their products working for me, help other enthusiasts do the same, and also present my highly opinionated results of the use of their products here. The information presented comes from my own experience and carefully considered opinion, and can be used (or not!), or ridiculed and laughed at, or worshipped, at the readers discretion. As with any recipe, your results may vary, and you are, and will always be, in charge of your own knuckles, and future!

You are welcome to use the information here in good health, and for your own non-commercial purposes, but if you reprint or otherwise republish this article, you must give credit to the author or link back to the SwEm site as the source. If you donít, youíre just a lazy, scum sucking plagiarist, and the Boston Globe wants you! As always, if you can supply corrections, or additional objective information or experience, I will always consider it, and consider working it into the next revision of this article...along with likely the odd metaphor and probably wise-a** comment.