Pic1. Exploded view of Amazon Wiper System.

Variations occurred over the production years, but this is representative.

Windshield Wiper Systems

Originally posted: Nov 2008, Revisions On-going, R. Kwas

[Comments added!]

Links other Wiper related pages:

544 Wiper Info

Wiper Arm and

Blades Notes

------------------------------------------------------

General

“Segment” Gearbox

System

“Cable-on-Cam” System

Different Motors and

Different Circuits,

same Control

Color Code Inconsistency

Considered

Wiper Motor Assembly Suppliers

Field Motors:

Autolite/Prestolite

AutolitePrestolite_Park_Switch

Electrolux

SWF

Permanent Magnet Motor:

Bosch

Test

Refurbed Wiper Motor Assembly

Review of the Design and Materials

Review of Function and Failures

Typical Symptoms of Problems

Wiper Servicing Procedures

Inspection of Components

Repairs

Frozen Wiper Drive Shaft Repair

Improvements

In-Situ Bushing Lube Procedure

Intermittent

wipers

-------------------------------------------------------

The Simplest Reason for Non-functioning Wipers

-------------------------------------------------------

Notice of Error in Factory Manual

-------------------------------------------------------

ADDITIONAL:

Dynamic

Braking

Symptoms of Failure of

Dynamic Braking

Wiper Park Function

explanation and differences between Motor without, and Motors with, Dynamic

Braking

Reference Information on

Compound DC Motors

Wiper Switches Compared:

122 Wiper Switch

1800 Wiper Switch

544 Wiper Switch

Link to a related SW-EM Tech Article:

Wiper Parking

Side

Notes (or, Right is Right, for LHD, and Left is Left, for RHD!)

-------------------------------------------------------

General: Several different wiper systems were fitted on 544, Amazon and 1800 models. I have zero experience with the (interesting!) early vacuum operated ones (which I understand were known for not working so good when climbing mountains...that makes sense: Full throttle gives low vacuum with which to run vacuum driven wipers!), so this article will concentrate on the electrical motor driven ones. Various motor/gearbox mechanisms were supplied by Auto-Lite/Prestolite, Bosch, Electrolux, and SWF.

Three Gearboxes System: What I call the Main Gearbox (2) contains the main reduction gear, and the “Home” or “Parkswitch” combination. This is one casting with the motor assembly which is (soft) mounted with rubber isolators (10) to a sheetmetal overall assembly (3), and this assembly is centrally mounted under the dashboard of vehicles. The sheetmetal overall assembly assures the permanent correct alignment of the linkage arms of the assembly, and the integral Parkswitch keeps power applied to the motor even when the driver has turned OFF the control switch, when the wiper-arms are not in the parking position, and continues to do so, until the position is reached. This assures that wipers always park out of the drivers view...nice modern touch! A provision for changing the side on which wipers park, was even included in some Parkswitches, to accommodate Right-Hand-Drive (RHD) vehicles. (See: Wiper Parking Side Notes).

Pic1. Exploded view of Amazon Wiper System.

Variations occurred over the production years, but this is representative.

The second, what I call “Segment” Gearbox System (4), of which there are two, is located just under where each wiper drive shaft penetrates the cowl on vehicles. It consists of a partial segment input gear (Pic 2, no number), which has an actuating lever which gets driven by a conn-rod and a full output gear (6) whose shaft then drives the wiper arm. Both gears are beefy and made of quality steel, and I’ve never seen any fail or even appreciable wear on either (which says a lot for the quality of materials and design margin!). The segment gearbox is filled from the factory with a heavy grease, and both segment gear and output gear shafts are located and run in brass bushings, with the bushing of output gear shaft being longer to give maximum support for the serious forces involved and also to allow it to penetrate the cowl to just below windshield.

Pic 2. Exploded view of Segment Gearbox showing input segment gear,

and full gear, which in-turn drives the wiper arm.

The con-rod supplying the reciprocating drive to the segment gearboxes, sweeps the segment gear about 60 degrees, and there is a slight step-up in degrees of sweep at the output gear (and wiper-arm).

“Cable-on-Cam” System: On 1800s and late production 122s, wire-type, a “Cable-on-Cam” linkage system was used. The mechanical action of this system is similar to a rack and pinion, but way less expensive to produce with sheetmetal and a thin, flexible, multi-strand steel cable, than precision cut gears. This assembly is similarly centrally mounted under the dashboard of vehicles, because all of the critical dimensions are the same as the Segment Gearbox type mechanism. The two mechanical systems are in-fact interchangeable. I don’t know who supplied the “Cable-on-Cam” systems, but from the lesser level of quality (and reliability LINK to Service Notes), I’d be willing to bet a hot fudge sundae it wasn’t a Swedish firm!

Pic3. Exploded view of the wire type “Cable (21)-on-Cam(14)” Wiper System.

Different Motors and Different Circuits, same Control: A number of different manufacturers supplied motor assemblies, and these assemblies had different strategies for implementing the two speed operation and Parkswitch, but all of the (earlier) variations connected to the Wiperswitch with a harness with Red, Green and Black wires. This means that Wiper Motor Assemblies can be interchanged as long as the color code is observed during hook-up at the switch. Note: The reader may notice an inconsistency in the color codes of the harnesses of the correct hook-up in (my) extract below, from the vehicle wiring diagram below...the IGN power is brought to Wiper Switch with Red wires, and connected to terminal P, but it connects not to the Red wire of the harness going to the Motor Assembly, but to the Green! The wiring and color codes shown are correct, and should be connected as shown.

The (factory) extract shown in the Green Manual: Part 3, Electrical Sytem, 120 (12Volts) is full of errors, both minor and major, and should be avoided alltogether!! See: Link: Notice of Error in Factory Manual.

Extract of Wiper Wiring from just about every 122 vehicle Wiring Diagram I've

ever seen. Inconsistency in color code at P terminal of switch is apparent

(spelling error notwithstanding!). Detail of the switch internals is very

good but detail of the Motor Assembly with its Parkswitch is totally lacking (I

expect this is because the Motor and harness assembly was expected to be

replaced as an assembly)...but when we work on it, and in it, we need a bit more

info! The 544 and 1800 Wiring Diagrams show even less or incorrect

switch detail! (References:

Amazon Wiperswitch ,

1800 Light Switch, Wiper Switch,

Fan Switch Drawing Corrections )

Color Code Inconsistency Considered: Red is Ign Power coming in (from Fuse 1), but it is directly connected to Green at Switch, which then runs off to Park Switch in Motor Assy, and Red wire between Switch and Motor Assy is for Motor Field and speed control [Don't be fooled by this inconsistency of color code with multiple Reds and Green wires connected together at Switch, and Red wire from the Wiper Motor Assy not connected to other Reds! This documentation is correct for the implementation!].

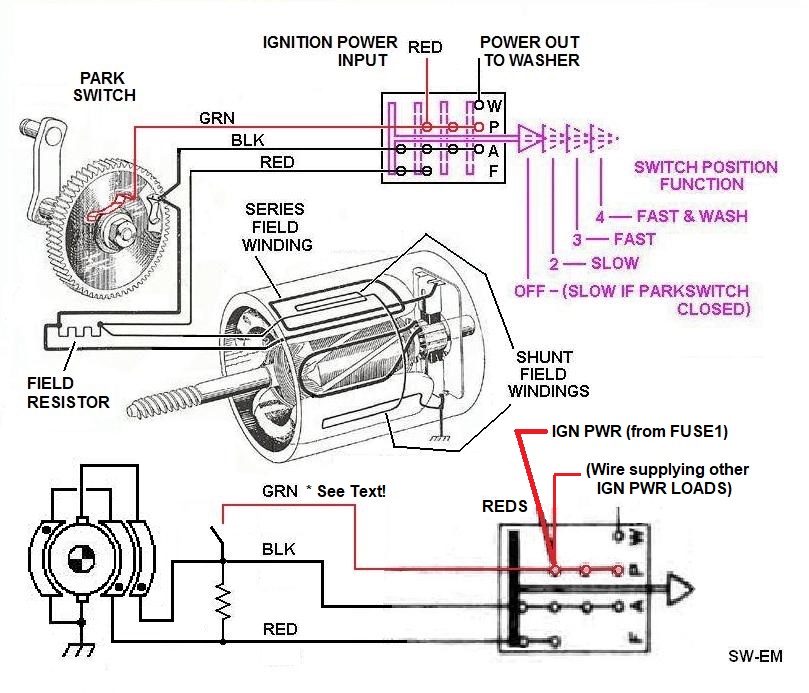

Here is a completely detailed Wiper Wiring Diagram

(Auto-Lite/Prestolite with 20 Ohm Field Resistor) showing the entire circuit.

Polarity dots are included on the Field Coils to indicate magnetic interaction

of the Compound DC Motor.

Notice the inconsistency

in the wiring color codes, with Red supplying power, connected to Green at the

switch Terminal P, and the (single) Red wire connected to

Switch Terminal F in harness running off to the Motor Assembly. This

wiring and color codes are correct and consistent with

Wiring Diagram,

and as

actually wired in the cars!

Picture Source: Factory Manual, plus my additions. Reference:

Wiperswitch

Notice that in Position 3 of the switch, power is removed from the Red wire which (fully) energizes the Shunt Field Winding (there is still a reduced energization by way of the 20 Ohm resistor)...but in this switch position, the motor runs faster...what gives? This is explained by what I call the "paradox of the DC motor"...that is, removing power (from field) allows it to run faster...this is counterintuitive, but not magic...there are trade-offs which explain the action.

[Compound DC Motors are complicated things!...for an excellent basic explanation of the different DC motor types, and the interaction of the multiple Field Windings, see: Reference Information on Compound DC Motors below or this link: http://www.ni.com/white-paper/14920/en/ ]

Because of the differences in the motors assemblies themselves, the internal circuitry is a bit different for each one, but again, all of the (earlier) variations ended at the wiper switch with a harness with Red, Green and Black wires. When servicing Motor/Parkswitch assembly and certainly when replacing components within, it is naturally important to first determine which systems you are working on. Mechanical parts are not interchangeable across systems! A separate section with functional explanation and identification info for each type follows:

Wiper Motor Assembly Suppliers (listed by type - A is Compound DC Motor and type B is Permanent Magnet [PM] DC Motor) :

A. Compound DC Motors with Multiple Field Windings for Speed Control (listed alphabetically):

General: The three Compound DC Motor assemblies supplied by manufacturers Autolite/Prestolite, Electrolux, and SWF are similar with variations. Outer diameters of all three motors are: 2 3/4". All three have a wormgear driving a maingear, but after that, there are variations in the specific mechanical and electrical designs.

Inspection and refurb generally means a carefull dissassembly, first by removing the main gearbox cover, cleaning away grease and inspecting internals. Restoring electrical contacts of the Parkswitch may be necessary, then relubing all contact and wear-areas in sight, before replacing maingear cover. The brush-end of motor can then be carefully removed, allowing a brush inspection, cleaning of the carbon dust which has collected as brushes have worn away, relubing of the motor shaft bushing and reassembly. A bit of ingenuity is called for during reassembly, in order to hold back the brushes while positioning the endplate back on motor...a helping set of hands, toothpicks, or temporary tape may help...so does gentleness and patience...

Presented here for reference are what I have found working on the different assemblies, the techniques I have used, which are intended to help the reader through an inspection and refurbing.

Compound DC Wiper Motor Assembly suppliers Listed alphabetically by manufacturer:

Autolite/Prestolite: In addition to markings on the motor itself, Autolite/Prestolite manufactured assemblies can be quickly identified by the carbon resistor mounted on main gearbox housing cover. These assemblies typically have a black sleeve protecting the harness running to Wiperswitch. (Reference: Wiperswitch )

Wiper assembly with Prestolite manufactured motor assembly,

including about 40 years of underdash munge.

Close-up of Parkswitch and motor connections. 20 Ohm carbon power resistor

is unique to Autolite/Prestolite manufactured assembly, and is the riveted

circular object,

with Red wire connection. The resistor is a source of waste heat in this

design,

but only in the switch high speed position.

Internal inspection of Parkswitch disc and contacts. Outer sliding

(interrupting) contact at Yellow,

looks well worn. Corresponding disc erosion and pitting of plastic back-up

surface is evident at Red, where motor current is broken as disc rotates.

Breaking the (inductive) motor current results in arcing and plasma which

generate lots of heat accelerating wear and contact erosion! See also:

Hot Switching vs. Cold-Switching a Contact

As can also be seen in the pic above, the Autolite/Prestolite supplied motor assembly is particularly susceptible to wear on the (outer) interrupting Parkswitch contact. This needs to be checked and corrected as required, as excessive wear will cause a change in the contacting position and this will eventually cause a dimensional change, resulting in the Park position of Wiper Arms changing.

Brush end of motor is opened for inspection. Lots of carbon dust from the

brushes is evident.

A wooden dowl locates brushes and keeps them from collapsing out of their

holders.

Right-most brush is clearly connected to chassis at Yellow, by way of its

braided cable,

as shown in the wiring diagrams.

After blasting away the carbon dust with brake cleaner, and drying, the motor shaft bushing oil supply felt ring is charged up with a few drops of oil. Allow to air-dry before applying oil, or speed this process with a blast of shop air. Do not use carb-cleaner for this, which may attack the insulating laquer of the magnet wire inside...that would be BAD!

Reassemble and Test Refurbed Wiper Motor Assembly Before Installation:

---------------------------------------------------------------------------

Electrolux: In addition to markings on the motor itself, later Electrolux manufactured assemblies are also recognizable by the molded black plastic cover which protect the Parkswitch and harness connections, and they typically have a green sleeve protecting the harness running to switch. These are, in my opinion, the nicest design of the three early type wiper motor assemblies I have seen.

Wiper motor assembly as manufactured by Electrolux, as removed from wiper

assembly.

Removal of Parkswitch housing allows inspection of external Parkswitch contacts

and harness

connections. Green highlights transfer pin which rides on a lobe inside

and actuates external contacts.

The actual Parkswitch contacts in the Electrolux design, are external to main gear housing, and are even a screw mounted design which would be very simple to replace. The cam follower design, where a pin transfers the switch actuation to the external Parkswitch contacts is nice, in that it saves the electrical contacts the mechanical wear, but the cam follower does not have a roller interface (just as on like the camshaft in a B18/20) so this mechanical connection must have its materials well chosen and be well lubed to prevent wear.

Separating main gearbox housing showing Parkswitch cam lobe (Red),

and spring loaded thrustwedge (Yellow)., Green highlights transfer pin which

rides on cam.

This gearbox is quite dry and in need of lubrication!

Don't forget to lube the motor shaft contact point on thrust wedge. I used and recommend bearing grease for worm and main-gears, and Parkswitch cam to transfer pin interfaces, and a tiny dab of anti-seize at the motorshaft contact point on thrustwedge. I applied two drops of synth oil to the bushing area where wormgear enters maingearbox housing, but I expect that grease migration from wormgear to maingear interface will keep this bushing well-lubed.

Commutator and brush and shaft inspection at other end of motor. Shaft has

no appreciable wear,

commutator doesn't have any appreciable grooves, and there's still lots of meat

on the brushes.

Plenty of brushdust is evident. Bronze shaft bushing in motor end-plate is

highlighted.

The dust from carbon brushes can be wiped away from easily accessible surfaces...a cotton swap will help with crevasses. Dust at the brushes themselves and more difficult to reach areas can simply be flushed away with a good blast of Brake Cleaner. Felt reservoir behind and surrounding the porous bronze shaft bushing should be recharged by dripping in several drops of (engine) oil...I like synthetic oil for this.

Reassemble and Test Refurbed Wiper Motor Assembly Before Installation:

---------------------------------------------------------------------------

SWF: I was not able to find any manufacturers markings on the motor itself, but after cleaning grime away, I finally spotted the manufacturer's definite logo in the main gearbox casting. SWF supplied assemblies typically have a black sleeve protecting the harness running to switch.

Wiper motor assembly as manufactured by SWF.

SWF assembly cleaned up before opening for inspection and refurb.

Logo is cast into housing (Yellow), but none is found on motor itself.

Red highlights thrust adjustment screw.

Parkswitch housing opened for inspection of disc and contacts.

Grease cleaned away to allow inspection. Parkswitch contact has worn nub

away (Red), but since wear is on inner (continuous) contact, a dimensional

change will not result, and so no change in Park position will occur as a result

of this wear either. Outer (interrupting) contact looks very good, Green

points to a single ball bearing which is a thrust bearing for maingear.

Care should be taken not to overlook and loose this tiny part during cleanup.

Although circles are polished into the switchdisc, the are no grooves worn in,

thanks to good quality materials and lubrication. Gasket has been

slightly damaged during disassembly (Yellow), but can be trimmed, and reused.

I would call this a medium mileage motor!

Worn contact could have new Beryllium - Copper material soldered to it, but this is not yet critical or absolutely necessary at this level of wear...I suppose I should have done this for the sake of showing it here...who knows when the next time will be, that I'll be in this assembly!

Brush end, motor endplate opened for inspection. Commutator looks typical

and has no grooves worn in. Plenty of copper and carbon dust is present,

but the brushes still have plenty material and life! Two rubber bushings

(Red) soft-locate the brushplate in a recess in the motor housing. The

shaft rotates in a porous bushing as in other manufacturer's motors. The

bushing has an oil supply felt ring surrounding it, which should be recharged.

I use a few drops of synthoil for this.

Cleaned up motor endplate. Rubber bushings are both in their proper place

before reassembly. Shaft bushing oil reservoir felt has been recharged

with a few drops of synthoil.

Reassemble and Test Refurbed Wiper Motor Assembly Before Installation:

----------------------------------------------------------------------------------------

B. PM Motor with

Multiple Armature Energization for Speed Control:

Bosch: I have also seen this style installed on a European delivered Amazon, and it is also shown in the manual for 140s. The motor is a Permanent Magnet (PM) type with no field winding(s). Because of the lack of bulky field coils, these motors are also identifiable in that they have a smaller 2 1/4" outer diameter than the motors with field coils. On the assembly I studied, the motor itself did not have any manufacturer markings stamped into the casing, it was stamped onto the sheetmetal Parkswitch housing cover, I presume therefore that it was also a Bosch motor, but this is not confirmed.

This style motor in unique in that it has three brushes bringing power to the armature with which to implement two speed operation, and their dynamic braking does require them to have a more complicated three contact Parkswitch (5 terminals total on external terminal strip, see pic!).

[For their unique wiring, refer to diagram below: Wiper Circuit with Bosch Permanent Magnet Motor and Dynamic Braking]

Bosch

PM Wiper Motor Assembly opened up and

cleaned of grease to reveal

a Parkswitch disc and contacts in very good condition..there's still

plenty

of material on the contacts and no grooves are worn into the switch disc.

I would call this a low-mileage motor assembly!

Wiper Circuit with Bosch Permanent Magnet Motor and

Dynamic Braking. Reference:

Wiperswitch

PM Motor Operation Notes: A single brush supplies the DC return (-), to the armature, and the other two brushes apply running power. One terminal (only) is powered for slow speed, and the other terminal (only) is powered for fast speed. Since the magnetic force of the PMs remains constant, speed dual speed is strictly determined by armature current and resulting magnetism. Motor is supplied, and runs at slow speed during parking.

Dynamic Braking: Not to be confused with "The Charles Atlas course with Dynamic Tension...which will turn you into a beast of a man." The Who Sell out, 1967! Reference: Important information from Charles Atlas ) is used in the PM motor design to quickly stop rotation once power is removed. That is, in addition to (and sequentially immediately after) opening the (slow speed) power path to the motor as it rotates the contact disc, the Parkswitch then connects the slow-speed power input terminal of motor to DC return (chassis). There are variations in the implementation of this also (in the ’67 Amazon, for instance, the chassis connection was direct at the terminal strip on the housing of the Parkswitch, in the circuit shown in the ’71 1800E manual, and even the 544 [which also has Dy Br], the chassis connection is by way of the switch at the dashboard). See further info on Dy Br below!

In either case, dynamic loading shunts to DC generated by inertia of the coasting motor armature, to chassis, resulting in its’ rapid slowdown and stopping. If this provision to load the armature was not present, the motor might coast past the Parking position. If a wiper system equipped with one of these PM motors exhibits problems parking (overshoots park position and keeps running...sometimes...this can be an intermittent condition), this current path should be suspect and checked. See also: Symptoms of Failure of Dynamic Braking:

Parkswitch and Intermittent Wiper Control : Of note is also the configuration and function of the Parkswitch, and that it is different in PM motors from motors having electrically powered Field Windings. This Parkswitch is effectively a Single Pole, Double Throw switch, connecting the Slow winding of motor to either power (to continue to run even after driver has set the Switch to OFF) OR nothing (transitional), OR chassis (for Dynamic Braking). Because of this, it is NOT possible to use a simple, single contact Intermittent Wiper Control (IWC) with PM motors. A more complicated IWC such as the Hella 5WA-001-871 which accommodates the PM motor must be used. See also Intermittent Wipers below!

The Bosch motor has an internal thrust bearing. Thrust clearance is not externally adjustable on this motor style.

Test Refurbed Wiper Motor Assembly Before Installation:

This test applies to all motor variations, and is most simply done by using a suitable 12V source (bench supply, or battery, current limited / fused to limit available current and possible damage(!), to 5-10A), and connecting the wiper harness normally to the switch (12V to P terminal of switch which has Green harness wire connected to it), and negative to any handy place on the assembly metal. Refer to Normal Wiring Diagram for this.

Motor should run as expected in the various switch positions:

Pos 1. OFF (Motor continues to run at slow speed until

stopping at Park Position, if switch is placed in "OFF" position mid travel)

Pos 2.

Slow

Pos 3.

Fast

Pos 4.

Fast (and washer pump motor when connected in vehicle).

If a switch is not available, a temporary equivalent hook-up can certainly also be used. If Motor Assembly functions as expected, it can be reassembled onto the wiper assembly.

Review of the Design and Materials: The design of the all vintage Volvo wiper systems, be it the DC Motor with Field Windings, or PM Motor, with three gearbox type or the single gearbox and cable-on-cam drive types, is quite robust...they need to be...moving rain or heavy slush from the windshields is important business in Sweden! Wiper systems are beefy and highly reliable as a rule, but in the long-term, weaknesses do surface.

All gears of the segment gearboxes run in brass bushings, a sign of good design, but because of the location of the gearboxes, right under the drive shaft which leads to the (sometimes wet) outside world, the shaft-in-brass running bushing and grease are subjected to tougher duty. A sealing ring is included in the design (Pic 2, 10)...I have never seen the main gearbox grease dried up after forty-plus years of service, but I always see the segment gearbox grease dried up and not lubricating the works, and I have even seen the driveshaft-in-bushing frozen solid in the running bushing due to lack of lubrication. Fortunately, the gear material and highly under-stressed design help to keep them from chewing themselves apart... My repair of the frozen shaft, without disassembly and shaft removal, is covered below: Frozen Wiper Drive Shaft Repair.

Review of Function and Failures: The motor drives the main reduction gear by way of a worm-drive. This gives the huge step-up in torque with a corresponding step-down in speed called for.

[Applicable to three gearbox system]: An approximately 1.25” radius bell-crank lever system is connected to the main reduction gear, and connecting rods transfer the slow, powerful circular motion, to a reciprocating action of approximately a 2.5” at the segment gearbox levers. The segment gearbox gear ratio gives a slight speed increase, and transfers the drive up through the cowl to just below the windshield, where the wiper arms are connected and moved, to do the actual work.

[Applicable to, cable-on-cam system]: A similar 1.25” radius bell-crank lever and conn-ron actuate the drive cams. The steel cable assures that the cam remains in contact with the reciprocating actuating rod. The less robust sheetmetal and cable design of the cable-on-cam system is susceptible to stretching of the connecting cable, or deforming the “double-D” shaped pulleys at the axles over the longhaul, especially when wipers are heavily loaded moving more than just rainwater. (LINK to Service Notes). Both of these conditions result in slop in the system, which manifests itself as lost motion and results in a pause during the direction reversal. Adjusting the cables can probably be performed with the assembly in place by the right mechanic...that is, a mechanic who is part contortionist and part Saint for the patience which he would have to exhibit to operate the tools up there, behind the dashboard (while practically handcuffed!). Repair of deformed pulleys most probably requires removal of the wiper assembly, although a really special mechanic, part-welder, part-contortionist, part-Saint might be able to TIG weld the shaft onto the pulley to eliminate the slop between the two.

General Electrical Problems: A problem which shows up seemingly as a wiper system issue, is a particularly slow wiper speed, but this is often really caused by a low voltage condition due to poor connection(s) in the supply path. These typically occur at the Fuse Block (for an Amazon, this is covered here: LINK: Gas Tight Joint, and for the 1800, it is covered here: LINK: Gas Tight Joint Part II).

Also, since the motors of all mechanism variations are soft-mounted by way of rubber vibration-(and also electrical) isolators on the frame, occasionally, the wire which hops the electrical chassis connection over this insulation can become dislodged and disconnected. Complete loss of wiper function results because the motor has lost return current path to chassis. If you experience complete wiper function failure, after checking the motor is getting power from the switch (associated fuse intact?), this is the next simple thing to check!

Electromechanical wearout issues include brushes of the DC motors and contacts of the Parkswitch.

Mechanical wearout issues: I’ve never seen the brass bushings of the segment gearboxes wear in “high-mileage” mechanisms. Sluggishness due to lack of lubrication of segment gearboxes and shafts after all grease has dried up and oxidized. If you don’t want your motor doing it best impression of a burrito in a microwave (cooking from the inside), investigate and remedy ASAP!

Typical Symptoms of Problems: In my experience, slop in the action of the wipers is the most common indication of problems (loose mechanism somewhere along the line, verified by a visual inspection of the linkage), followed by problems parking (worn or damaged Parkswitch contacts), unfortunately this condition is not inspectable without removal of at least the motor (only) first. Wiper arms falling off the drive bushing when mechanical connection of splined bushing to wiper-arm gets loose is also pretty obvious! LINK to Repair in Service Notes.

The later cable-on-cam mechanism is somewhat more susceptible to wear-issues because of the lighter duty construction. Unfortunately when mounted in an 1800, the wiper assembly also cannot be as simply removed as a unit from under the dashboard of an Amazon...in fact, I believe the upper dashboard of an 1800 must be removed to gain access enough to remove the wiper drive assembly...I guess that’s the price one has to pay for having a sleek sportscar, and that’s why it’s also a very good idea to thoroughly service the wiper system anytime you have the windshield and/or dashboard of an 1800 removed for any reason! For Parking Switch inspection, that really patient mechanic might be able to extricate the motor alone from the assembly...by removing linkage securing clip (Pic 3, 11), and the 3 securing bolts (Pic 3, 4)...don’t call me!

Electrical problems will typically show up as a slow or sluggish, but slop-less, wiper action. A voltage-check, at the switch and motor under load, are good next steps here.

Wiper Servicing In Situ: Short of applying a drop of lube to the nylon bushings on the conn-rod linkage points (or heavy grease to the cable contact area on cable-on-cam mechanisms of 1800s), there is not much which can be serviced on the mechanism while installed. On a recent mechanism assembly which I removed from an Amazon for repair, the wiper driveshaft had totally frozen in the running bushing(!), and upon disassembly there was evidence of corrosion damage in the segment gearboxes proving that water had made it past the bushing. I came up with an In-Situ Bushing Lube Procedure in response, which I now recommend, as I believe lubed bushings would have substantially prevented the condition.

Removal of Wiper Assembly (122 model):

Removal of Wiper Assembly (1800 model):

Link to Procedure by SW-EM Guest Contributor John Finn: Wiper_Assembly_Removal_of_from_an_1800S.htm

Test of Complete Wiper Assembly Function outside Vehicle 122 or 1800:

Inspection of Main Gearbox and Parking Switch:

As a rule, the different motors have identical three mounting bosses and so are interchangeable onto the mechanisms. BUT, these can be interchanged if the correct switch is included, since there are electrical variations of motor and switching. Therefore I recommend Switch, Harness, Motor should always be replaced as an assembly to prevent electrical issues.

Repair of Homeswitch contact: On high wear motor assemblies, the contacts which slide on the homeswitch disc can be worn to the point of changing the physical point of contact. This causes sloppy homing action (sometimes wipers stop here, sometimes there...). I have effectively restored the contacts to their original dimension by soldering on Beryllium copper spring metal extensions. Normal copper alone is probably too soft and not suitable.

Frozen Wiper Drive Shaft Repair: Unfortunately, after decades, the wiper drive shaft-through-bushing can become bound up in the bushing as a result of lack of lubrication. The warning sign of this is a sluggish wiper action (although a low operating voltage on the motor will manifest itself in the same way), finally, once completely bound up in the bushing, the motor load and consequently motor current drawn will be sky high...if fuse doesn’t blow under this condition, and it may very well not (being sized to accommodate the total current of many additional loads), turn OFF power to wipers (or motor will surely burn up!). Repair and Lubrication is required! The ideal fix would be to completely disassemble the works, free the shaft, remove it from the brass bushing and reassemble with proper lubrication, but this would require complete removal of the wiper assembly and disassembly of the shaft through the bushing which in-turn would require the wiper arm coupling bushing (Pic2, 11) to be removed from its shaft with a puller. This would allow the shaft to be withdrawn completely from the bushing, and allow complete access to clean, and apply lube to the shaft, BUT, the wiper-arm coupling bushing would then have to be pressed back on for proper reassembly. Because getting this pressing operation right (to be capable of the significant forces on the mechanism), I consider this path way beyond even a serious home mechanic, so I recommend against it. I proceeded like this:

Without disassembly, the shaft needs to first be lubed and gently but firmly rotated to free it up. Here is my experience: With the assembly held in a vice, bushing downhill, such that a penetrant like LINKS: WD-40 or PB Blaster would run into the bushing area and shaft end of the gearbox, I gently applied just enough torque to a wiper arm (temporarily installed on the drive bushing) to free up the frozen shaft. Once the shaft was somewhat freed up and able to be spun by hand, I soft-coupled it to a handdrill, using a piece of 1/2" ID rubber tubing, and spun it in both directions for a few minutes until totally free. After rotating the shaft in its freed and lightly lubed bushing for a while, the shaft-in-bushing action was once again totally smooth and without the slightest resistance to turning.

Segment Gearbox secured in a vice, with corrosion, remains of dried grease

(yummy!) and

newly applied penetrants are visible. A Wiper Arm is temporarily installed for

(gentle but persuasive) leverage to unseize the shaft.

When I was satisfied that the shaft was perfectly freed, I flushed the penetrants away as best as possible with carb cleaner (LINK: Carb Cleaner) while spinning the shaft, in preparation for applying permanent lubrication. In order to totally flush the bushing, of penetrants (which wouldn’t do the lubes I’d be applying next any good) I flushed and repeated this operation a number of times, for a week until the shaft seemed perfectly free and clear to turn while dry.

Once the joint was perfectly flushed and clean, the joint needed to be filled with a long-lasting lube. I decided that graphite grease would be ideal for this low-speed/high bearing pressure application (I just love the shear properties of LINK: Anti-Seize and its Graphite!). The trick would be how to get it to its working location without direct access. Gravity feed to the rescue again! By thinning out Anti-Seize with Tri-Flow precision Teflon oil (my most favorite light oil! LINK: TRI-FLOW) and filling the segment gearbox housing with this special mix, then encouraging flow of this cocktail by turning the shaft some more, the mix would creep down through the bushing gap, and be delivered to the running bushing, exactly where it was needed. I left the assembly in this attitude for several days. As the highest order solvents of the Tri-Flow then evaporated, they would leave behind low order oils and grease (not so bad), and solid PTFE and graphite particles (not so bad either!)...I figure that between all of those materials of lubricity (where’zat?), the shaft would be adequately lubed (and maybe sealed to the ingress of moisture) for a darn long time.

Gravity feed application of custom liquid lube cocktail. White oxidation

is visible

on inner surface inside gearbox consistent with water having gotten in

there!

After the procedure, I wiped up the excess, inspecting the full gear for its worn area and assuring that it was interfacing with the segment gear in a virginal area upon reassembly, then filled the segment gearboxes with a healthy glob of anti-seize and heavy grease mix. .

Reassembly of Wiper Mechanism...is the reverse of disassembly as they say. For the main gearbox, I recommend a generous portion of heavy (nonconductive) axle grease, and in the segment-box (where the conductivity of the metallic particles won’t bother anything!), a mix of heavy grease and graphite bearing anti-seize.

The only other thing to watch out for is getting the conn-rods from the motor and segment gears right (but this should be no issue if they were marked during disassembly, or a picture was taken). Since the segment gear movement is limited to about 60 degrees of reciprocating sweep, it must be connected to the driving conn-rod such that segment gear doesn’t get driven into the gearbox wall, which could happen with incorrect assembly. To prevent this, assemble the drive gear and conn-rod linkage except for connection to motor-arm, and manually operate the conn-rod through a simulated full cycle of the motor-arm. Incorrect assembly should be immediately obvious.

The bellcrank linkage ends have nylon bushings for silent, low friction action. A drop of wax or silicon type lube on the post part of the junction couldn’t hurt here.

See also: Windshield Wiper Linkage repairs in Service Notes

In-Situ Bushing Lube Procedure (Gravity feed lubing of the bushing, suitable for 122 or 1800):

[Preventative Lubing In-Situ anyone? The beauty of a gravity-aided-flow-of-lube-technique is that the technique can be adapted to be performed while the wiper assembly is still mounted in the car! That is, the wiper arms can be removed, tubing sections applied to the posts to make some temporary reservoirs , filled with thinned graphite grease, and wipers powered to encourage the lube to migrate, up and down, into the running bushing...simple...one might even consider performing this as a maintenance operation after five decades of service...and having seen the frozen wiper driveshafts, I recommend it! ]

Diagram of wiper running bushing lubrication process,

which can be used without removal of wiper mechanism.

Intermittent wipers: [This sections needs further work and details.] Once the wiper system has all its moving parts rebuilt and lubed to perfection, it will likely be able to run failure-free for another fifty years...but the rest and cool-down which the upgrade to an intermittent control brings for the motor between wipes, or simply the occasional wipe, is still really nice. Installing an upgrade to add the intermittent function is not difficult, but differences exist because of the different styles of motors and Wiperswitch circuits which were fitted. BEWARE: An intermittent control system suitable for the Compound DC Motor with Field Windings is not suitable for the PM Motor, which requires Dynamic Braking!

Considerations and Requirements:

Things one needs to think about and decide on before

incorporating an Int Wip Cont.

1. Decide on location of control switch or knob. This obviously

varies with vehicle models, and owners preference. The author has seen

some compact units which would even fit behind the Dashboard and allow the

control knob to protrude through a hole above the OE Wiper Switch. If the

somewhat extreme and irreversible act of putting a hole through the Dashboard is

a bit too violent, self-contained units are available and nice in that they can

be mounted under the dashboard in an easily accessible location.

The Int Wip Cont must be suitable for use with Switch and

Motor.

1. A Simple closing contact will often work with the Field Motor. An

example of a modestly priced one and source are shown here:

2. A Perm Mag Motor requires a control with both a closing and an opening

contact.

Intermittent Control of Wipers with Compound DC Motors with Field Windings: An electronic Intermittent Wiper control can be simply connected across the parking contacts of a wiper system equipped with one of these motors. By closing the contact of the intermittent control for a half second or so (only), the motor is energized enough to move the mechanism (and more importantly: Parkswitch) from the park (open contact) position, so the wipers start to sweep...the parking switch contact then closes and supplies power to motor to complete a single slow speed sweep, parking at the home position again....the waiting time until the next pulse and sweep is then simply adjusted at the electronic timer.

PLACEHOLDER FOR Wiper wiring circuit with intermittent function modification, Compound DC Motors with Field Windings.

Intermittent Control of Wipers with PM Motor and Dynamic Braking: Because the contact of an intermittent wiper control needs to take into account the switching action of the Dynamic Braking provision, installing an Intermittent Wiper control on a wiper system with a PM motor is a bit more complicated. The intermittent circuit timer contact may not be simply connected across Parkswitch, because if it were to close, it would short 12V to chassis through the dynamic braking contact which is still closed, resulting in the poofing of something!

Repeated from above: Parkswitch and Intermittent Wiper Control : Of note is also the configuration and function of the Parkswitch, and that it is different in PM motors from motors having an electrically powered Field. This Parkswitch is effectively a SinglePole, Double Throw switch, connecting the Slow winding of motor to either power (to continue to run even after driver has set the Switch to OFF) OR nothing (transitional), OR chassis (for Dynamic Braking). Because of this, it is NOT possible to use a simple, single contact Intermittent Wiper Control (IWC) with PM motors. A more complicated IWC such as the Hella 5WA-001-871 which accommodates the PM motor must be used. More is coming on this!

PLACEHOLDER FOR Wiper wiring circuit with intermittent function modification, PM Motor

[Note: Jun 2015 - I have recently devoted much time understanding this subject further, particularly the unusual combination of PM Motor and Rocker Switch as fitted by the factory into the '73 1800ES, in comparison to the other, more commonly fitted Motor Pullknob Wiper Switch combinations, but have not included the extensive notes here. Bottom, line is that if the reader is interested in adding an Intermittent Wiper Control to this or any other vintage Volvo model, please contact me by way of e-mail, and I can work with you on this modification for your specific vehicle variation.]

-----------------------------

The Simplest Reason for Non-functioning Wipers

-----------------------------

Links to discussions on the subject:

LINK Thread to: Survey of what Wiper Motor and Gearbox combination was installed on what year, model and Chassis No. vehicle. http://www.brickboard.com/RWD/volvo/1314099/120-130/survey_wiper_system_wipers_windshield.html

Link to Brickboard thread: 544

Wiper Speed:

https://www.brickboard.com/RWD/volvo/1619330/444-544/544_wiper_speed_new_info_old_thread.html

My response:

Forum;

I ran across this old thread, and am bumping it back up to the top because I

have a possible/likely cause of the fast motor, and some explanations which

hopefully will help some owner: Fast DC motor running is caused by an open Field

Winding

To effect a high motor speed on a "Cumulative Compound DC Motor with Long

Shunt", the Field is deenergized...this is counter-intuitive (and there is a

starting torque loss price to pay), but if the Field winding of your motor were

to have opened up (for any reason), this would be electrically the same as

placing the switch of a two-speed setup in the Fast position. (See Reference

links)

If you're lucky, disassembly and internal check will reveal only an open

connection to the Field coil (which can be repaired, and which will bring slower

speed operation back)...if you unlucky, the visible connections are fine, but

the Field coil is internally open (this is unfixable for all but motor

specialists who will have special fixturing and techniques with which to wind a

new Field coil of the right wire gauge and physical dimensions)...

However, the speed could STILL be brought down to slower by wiring in a PWM

controller for a DC motor (alternates between applying full power and OFF at a

rapid rate which translates to a slower motor speed, but still with decent

torque...opposed to simply putting a Dropping Resistor in series and applying a

reduced but constant voltage, which gives poor motor performance and also

results in excess motor heating, not to mention the significant wasted heat in

the Dropping Resistor).

Reference Links: http://www.sw-em.com/Windshield%20Wiper%20Systems.htm

...look at: Different Motors and Different Circuits, same Control:

...and: http://www.sw-em.com/Windshield%20Wiper%20Systems.htm#Reference_Information_on_Compund_DC_Motors

Info on Dropping Resistors: http://www.sw-em.com/Vintage_Volvo_6V_to12V_conversion.htm

...look down to "Dropping Resistors"

Hope this helps someone.

Cheers

-----------------------------

Notice of Error in Factory Manual: I ran across this wiring diagram, I believe to be full of errors, both minor and major, in the Green Factory Manual no less Part 3, Electrical Sytem, 120 (12Volts). The Green Factory Manuals are still generally the most complete and best out there, but I guess everybody can have a bad day!

Error 1 (Major). In the diagram, it shows the Black and Green wires of the Motor Assembly Harness swapped as they connect to the Wiper Switch. [This error has the functional jeopardy in that if one were to really connect the Black wire of the wiper harness to the P terminal of Switch as shown, then turn on IGN power, the wiper would run continuously and not be controlled, (or controllable!), by the switch!]

Error 2 (Minor). The Series Field Winding within the Motor Assembly is shown on the low side of the Armature...it is in fact on the high (power) side...Black wire connects to Series Field, then to Armature whose low side is connected to chassis. [This is strictly a documentational error which results no functional jeopardy.]

Error 3 (Major). Two Shunt Field Windings are shown, and one is even shown connected to the Black wire (Armature power). [This is strictly a documentational error which results no functional jeopardy.]

RED errors are highlighted and my GREEN corrections are shown.

...if I'm all wet here and this is some version I haven't run across yet (which might be possible), the reader is most welcome to show me the error of my ways and correct me!

--------------------------------

Reference information:

From a popular reference source under Dynamic Braking: "Dynamic braking can also be achieved by shorting the motor terminals, thus bringing the motor to a fast abrupt stop."

Important information from Charles Atlas

-------------------

Wiper Park Function explanation and differences between Motor without, and Motors with, Dynamic Braking:

In Worm Gear systems as found in the 122 and early 1800, stopping the Wipers in a preferred position, aka "Parking", is as simple as removing motor power when the mechanicals are in the appropriate/desired location with a position sensitive slider switch aka Parkswitch. This is a Single Step Process! This is accomplished with various implementation of the Simple Parkswitch, as shown below. When driver returns the Wiper Switch to the OFF position, depending on the immediate state of the Park Switch in the mechanism, which still has the ability to override the driver operated switch, and apply power to the motor to complete a wipe...Parkswitch opens when mechanism reaches the Park position, and movement stops.

In the 544 (similar to later 1800 and 140) vehicles, where Dy Br is required (to prevent coasting over the preferred stopping point), action of Park Switch is more complicated, as not only does the Park Switch cut power when Wipers are at the Park position, but it subsequently (and immediately after that, never during! * ) connects the motor terminals to chassis and this brings to motor to a fast stop. It does this in conjunction with the Wiper Switch (in some implementations such as 544 and late 1800). Wiper Switch of the these systems is also more complicated in that it not only applies power to the motor, but it also applies a negative chassis connection (only) in the OFF position as shown below. In some implementations, the negative chassis connection only takes place within the Parkswitch assembly (internal to the Motor Assembly)...in other implementations, the Wiper Switch is involved to make the chassis connection in the OFF position. This is an example of the many variations of implementation...

In this wiring diagram showing Wiper Switch internal connection details (140

Wipers),

it can be seen that chassis connection is routed to Motor Assy through switch,

and only in the OFF position (0).

Dynamic Braking explained: When electrical power is applied to a DC motor, it turns to move its load (it draws a high initial current while its coming up to speed...its own inertia is also a load!). Once motor is up to speed, it draws a lower current to maintain its normal speed, but it also has energy in the form of rotational inertia (mechanical energy storage of braking energy in a rotating flywheel is the basis for some electric vehicles!...they don't simply use friction brakes to turn the kinetic energy into heat which is wasted overboard, but they harvest it and save it on the flywheel!) ...if we simply remove the electrical power, that inertia does not instantly disappear, but will cause the motor to coast down and only eventually stop. In many applications, this coasting down is not a problem, but in the Wiper application, where position at stopping is rather important, this coasting down is not desirable. It would be nice to minimize it. This is where the principle of Reciprocity comes in...where before, we applied elec power to the motor and made it turn, now we use the fact that a turning motor immediately after removing power, is generating electricity, to stop it from turning...if we load down that electrical power being generated, pretty heavily, namely with a connection to chassis [yes, in other words a short, but its OK in this case, really...read on!], we bring the turning motor to a very quick stop, and our requirement for a specific stopping location is satisfied.

* So the turning OFF of a motor in this case is a Two Step Process: 1. Remove Power. 2. Load the Generated Power of the turning Armature, and since it would be a serious problem if we inadvertently shorted the incoming power to chassis, the system has to be designed to absolutely prevent this from happening, and if we take into account that all of this wants to happen at a certain position, the answer becomes clear: The position sensing slider of the Parkswitch is modified to do both!

A quick way to tell if Park switch is a simple one or variation with Dy Br is by inspection of either the mechanical part, or even just the number of connections. A simple Parkswitch has only two connections, while a Parkswitch for a motor with Dy Br will have three connections, as seen here.

Wiper Parkswitches compared.

Internal picture of the Parkswitch of an 1800ES Wipermotor Assy (same as 140),

where 3 contacts, (so with Dy Br!),

are separate from the rotating part, and

follow a cam. This arrangement has the advantage that

contact wear is less

likely to result in a change in Wiper Arm parking position

as in the Autolite/Prestolite

Parkswitch implementation above.

Rotor is shown in Park position

(center contact which rides on nylon position cam is making contact with outer

contact [with screw]

which is connected to chassis).

Picture Credit: Dave Farrington

Symptoms of Failure of Dynamic Braking:

From "Gerg's" posting in the VW world, dated Dec 03, 2009: http://www.thesamba.com/vw/forum/viewtopic.php?t=389208

"...wipers...would not park, they would stumble and then

continue..."

My Response: "...this is typical action of a Wiper Motor with Dynamic Braking, where the Dy Br is not working correctly (no chassis connection getting to the Motor at the Park Position, for some reason, typically either because Wiper Switch or Parkswitch in Wiper mechanism is not providing it). Power is removed, in Park Position, but inertia of the rotating Motor carries it across this unpowered "dead spot" (hence the "stumble"), to the other side, where it has power applied once again, which causes it to run normally...and this action will continue..."

[Unfortunately, I never saw any feedback confirming this was the cause of the faulty action, or repairs which remedied the issue, but as symptoms are classic, author does expect he had it right.]

-------------------

-Compound DC Motors from National Instruments site: http://www.ni.com/white-paper/14920/en/ (copied and included here with attribution, because they moved it and invalidated the link once already, and I don't want them to be able to do that again and loose the good information.)

The Wiper motor configuration used in the Volvo application is not specifically shown here [...now it is, see below!]...but I would believe it to be a "Long Shunt" connected variation of the 1. Cumulative Compound Motor, but info here is still quite helpful. I invite DC motor specialists to correct me on this if I have it wrong!

Figure 12-17a shows a diagram of the cumulative compound motor. It is so

called because the shunt field is connected so that its coils are aiding the

magnetic fields of the series field and armature. The shunt winding can be wired

as a long shunt or as a short shunt. Figure 12-17a and Fig. 12-17b

show the motor connected as a short shunt where the shunt field is connected in

parallel with only the armature. Figure 12-17c shows the motor connected as a

long shunt where the shunt field is connected in parallel with both the series

field, interpoles, and the armature.

Figure 12-17a also shows the short shunt motor as a cumulative compound motor,

which means the polarity of the shunt field matches the polarity of the

armature. You can see in this figure that the top of the shunt field is positive

polarity and that it is connected to the positive terminal of the armature. In

Fig. 12-17b you can see that the shunt field has been reversed so that the

negative terminal of the shunt field is now connected to the positive terminal

of the armature. This type of motor is called a differential compound because

the polarities of the shunt field and the armature are opposite.

The cumulative compound motor is one of the most common DC motors because it

provides high starting torque and good speed regulation at high speeds. Since

the shunt field is wired with similar polarity in parallel with the magnetic

field aiding the series field and armature field, it is called cumulative. When

the motor is connected this way, it can start even with a large load and then

operate smoothly when the load varies slightly.

You should recall that the shunt motor can provide smooth operation at full

speed, but it cannot start with a large load attached, and the series motor can

start with a heavy load, but its speed cannot be controlled. The cumulative

compound motor takes the best characteristics of both the series motor and shunt

motor, which makes it acceptable for most applications.

Differential compound motors use the same motor and windings as the cumulative

compound motor, but they are connected in a slightly different manner to provide

slightly different operating speed and torque characteristics. Figure 12-17b

shows the diagram for a differential compound motor with the shunt field

connected so its polarity is reversed to the polarity of the armature. Since the

shunt field is still connected in parallel with only the armature, it is

considered a short shunt.

In this diagram you should notice that Fl and F2 are connected in reverse

polarity to the armature. In the differential compound motor the shunt field is

connected so that its magnetic field opposes the magnetic fields in the armature

and series field. When the shunt field's polarity is reversed like this, its

field will oppose the other fields and the characteristics of the shunt motor

are not as pronounced in this motor. This means that the motor will tend to

overspeed when the load is reduced just like a series motor. Its speed will also

drop more than the cumulative compound motor when the load increases at full

rpm. These two characteristics make the differential motor less desirable than

the cumulative motor for most applications.

The compound interpole motor is built slightly differently from the cumulative

and differential compound motors. This motor has interpoles connected in series

with the armature (Fig. 12-17c). The interpoles are connected in series between

the armature and series winding. It is physically located beside the series coil

in the stator. It is made of wire that is the same gauge as the series winding

and it is connected so that its polarity is the same as the series winding pole

it is mounted behind. Remember that these motors may have any number of poles to

make the field stronger.

The interpole prevents the armature and brushes from arcing due to the buildup

of magnetic forces. These forces are created from counter EMF called armature

reaction. They are so effective that normally all DC compound motors that

are larger than 1/2 hp will utilize them. Since the brushes do not arc, they

will last longer and the armature will not need to be cut down as often. The

interpoles also allow the armature to draw heavier currents and carry larger

shaft loads.

When the interpoles are connected, they must be tested carefully to determine

their polarity so that it can be matched with the main pole. If the polarity of

the interpoles does not match the main pole it is mounted behind, it will cause

the motor to overheat and may damage the series winding.

--------------------------------------------------------

Do not mix and match switches without very careful inspection and tests to assure result of this action!

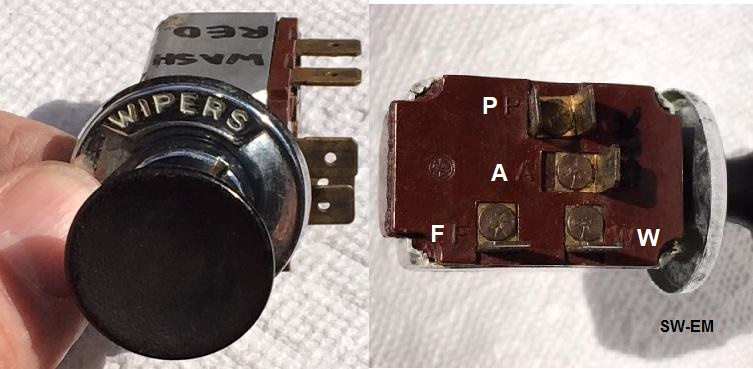

122

Four position Wiperswitch

OFF ( complete wipe and Park)

2 = Slow Speed Wipe

3 =Fast speed Wipe

4 =Fastspeed wipe, plus Wash

Functionally similar to the 122 Switch, but different looking as it was produced in Britain, and part of the harness supplied by Lucas (gag!...or some sub-contractor). (Link: 1800 Light Switch, Wiper Switch, Fan Switch Drawing Corrections )

1800 Wiper Switch in the middle.

544 Wiper Switch (Link: 544 Wiper Info )

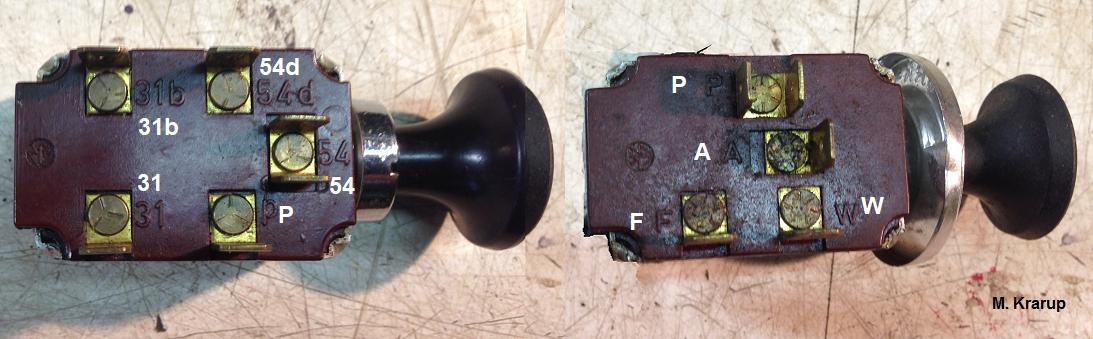

544 three position Wiper Switch on left (used on both 6 and 12V

installations, single speed, with P terminal for powering Windscreen Washer

motor) vs.122

four position switch on right. Picture Credit to M. Krarup.

1800 Wiper Switch (late):

1800 Switches before 73, switches were similar is style to 122...activated by Round pullknobs that is...[Note: This should not be taken to suggest that Motor Assemblies were also similar to a 122...they are likely not, as shown above!]

1972 Wiper/Washer Switch:

I have overwritten the visible writing to help with terminal identification (Scheibenwascherm.

is German for Windschieldwascherm[otor]).

This is a Switch for two speed Wipers, plus turn for Washer Pump). See

also Item 42 on '72

1800E Wiring Diagram!

For 1973, the 1800ES model got rocker switches:

Windschield Wipers and Washer Pump are separate Switches in the ES. See

also Item 42 on

'73 1800ES

Wiring Diagram!

These are similar to switch style also used in early 240s shown here, so this is a source for possible replacements.

240 Wiper Switch.

------------------------------------------------------------

Sources of external materials are attributed. Otherwise, this page is Copyright © 2008-2021, Ronald Kwas. The terms Bosch, Electrolux, Autolite/Prestolite, SWF, Hella, National Instruments, and Volvo are all used for reference only. I have no affiliation with any of these companies, other than to try to keep their products (including my vacuum cleaner) working for me, and to help other enthusiasts try to do the same. The results presented here are from my own experience, and carefully considered opinion, and can be used (or not, and ridiculed, and used strictly for your amusement, and laughed at around the water-cooler!) at your discretion. As with any recipe, your results may vary, and are, and will always be, in charge of your knuckles and future!

As always, if you can supply corrections, or additional objective information or experience, I will consider it, and consider working it into the next revision of this article...along with likely the odd metaphor and maybe wise-a** comment. You are welcome to use the information here in good health, and for your own non-commercial purposes, but if you reprint or otherwise republish this article, you must give credit to the author or link back to the SwEm site as the source. If you don’t, you’re just a lazy, scum sucking plagiarist...the Boston Globe wants you!