Brake Notes

01/03 R. Kwas [...terrifically

insightful comments added!]

General: PLACEHOLDER for a terrifically insightful paragraph about vintage Volvo Brakes...here it comes: Volvo Brakes have always been very good, considering for example, that the Calipers fitted were the same Girling units fitted on 6 cylinder Jaguars of the time. Before "upgrading" brakes because one is not satisfied with their effectiveness, it's recommended to return braking function back to how they performed when new...you might just find you wont think so much about "upgrading" after that!

Note that the "Live Rubber" from natural sources as was used years ago by Girling for seals and other components, has long been replaced by the synthetic EDPM equivalent. Unlike seals of "Live Rubber", this synthetic rubber is compatible with all Brake Fluid types. See: https://en.wikipedia.org/wiki/EPDM_rubber

-----------------------------

Brake Plumbing and

Fittings

Bleeding Hydraulic

Brakes

Special Tools for Tubing

Swollen Brakelines

Unacceptable Replacement Lines

Front Shoe, Rear Shoe

Discovery: Mismatched Threads on All Amazon Braking Systems with Hydraulic Brake Light Switches(!)

"Upgrading" Brakes

Links

Brake Drum Removal, Inspection,

Reassembly Notes

Manual Rear Drum Brake

Adjuster and Adjustment Notes

Girling Brake Vacuum Servo

Reference Information:

Red Rubber Grease

ATE Bremszylinder-Paste

CuNiFer Brake Line

Incorrect Assembly of Rear (Drum) Brakes on 122 and 1800

Vehicles causes Risk of Handbrake Failure

Factory Exploded Assembly Diagram Markup

Chicken-guano in DOT4 filled systems?

ABS explanation by analogy.

-----------------------------

Brake Plumbing and Fittings: When replacing brake system plumbing components, always triple-check to make absolutely certain flare connections are playing with their correct mates, both in flare type and threads! Mismatching Braking System connections causes leaks or failures which can be disastrous!

Type 1 is also known as a

"Bubble Flare" and Type 2 is the more typical "Double Flare".

Excerpt from Volvo factory P120 P1800 manual.

Brake plumbing fittings are checked against a 3/8" - 24TPI tap.

All factory original brake fittings, from Unions, to Brake Light Switch to Flare Fittings

to Bleeding Nipples, have the same thread size, but not necessarily the

same flare!

I have added the

longer Flarenut (L) required at the Caliper end.

Copper sealing washer, found on the single Flexline located at

Differential tube (single Hydraulic brake system).

------------------------------

Reference Information:

Types of Flares:

Simple Flare - Suitable for low pressure hydraulic

systems, like fuel, ONLY! Not used, or ever to be used on Brake

Systems!!

Double Flare - Suitable for high pressure hydraulic systems, like Brakes!

Typically used on US, and British vehicles. Used on vintage Volvos.

Bubble Flare - Suitable for high pressure hydraulic systems. Typically

used on modern European vehicles, but can also be found on vintage Volvos!

-----------------------------

Flare Detail: From: https://www.flickr.com/photos/29043759@N03/22998916614/in/photostream

Shown also in this graphic is the fitting style where the thread begins not

immediately at the end, but only after an

unthreaded area.

This does not play well with some Volvo components, see:

Unacceptable Replacement Lines!

below.

-----------------------------

Bleeding Hydraulic Brakes: (When Bleeding, the Rule is: Furthest from Master Cylinder first, to Nearest to Master Cylinder last!)

Overheard in the Garage:

Mechanic: Ready...Puuuush!

Assistant: Bottom!

Mechanic: Hold!

Assistant: Holding!

Mechanic: Release! ...Puuuush!

Assistant: Bottom!

Mechanic: Hold!

Assistant: Holding!

Mechanic: Release! ...Puuuush!

Assistant: Bottom!

Mechanic: Hold!

Assistant: Holding!

Mechanic: Release! ...How does the Pedal feel now?

Assistant: OK!...Daddy, are we done yet? Can I go to play

with Billy?

-----------------------------

Keeping Brake Fittings and Bleeders usable and from becoming one with components they are screwed into...

When encountering a Brake Fitting or Bleeding Nipple which needs loosening for the first time. Its always a good idea to spray on a bit of penetrating oil, such as PB Blaster, Croil, WD-40 (yes, although I dislike this product in general, and certainly as a long-term lube - which it definitely is NOT, it will work OK for this immediate penetration and lubing need) or even homemade penetrant cocktail of 1:1 ATF and Acetone, before attempting loosening it....then, break open the fitting with a wrench which acts on as many surfaces of the hex as possible, not simply an open-end wrench which only acts on two (See also: Special Tools for Tubing).

Located where they are, Brake hydraulic fittings tend to corrode in place, and that may be exacerbated by having been over-tightened by the last mechanic...and who knows...maybe the only person who ever tightened it was Inge back in 1967.

Volvo factory in 1967. Excuse me Inge ...are those steel toed flip-flops?

Volvo stock photo.

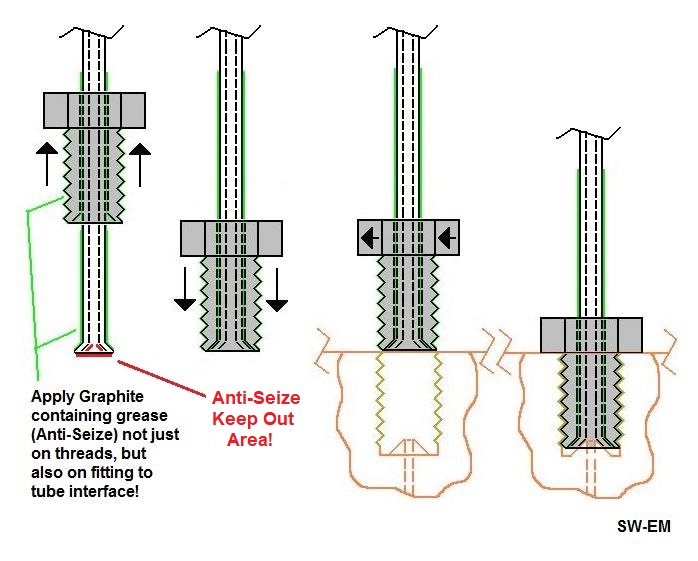

...of course if the last mechanic to touch the fitting was me, this is not an issue, as I always coat both threads of fitting and tube to fitting interface with graphite bearing anti-seize, and that is my recommendation for all owners.

Graphite on threads greatly helps with future removal, but this is of little help if

fitting has become one with tube and the tube twists

as one is loosening the fitting.

Graphite between fitting and tube also, prevents these from unifying! Note

Keep Out Area!

I have seen concerns mentioned about contaminating the Brake System with grease or graphite, but don't see this as an issue...in the first place, I apply it precisely and only onto the Threads, and Fitting-to-Tube-Interface (and not from 10 feet away, with a shovel) and not to the conical seal. In the second place, even IF a tiny bit were to find its way into the hydraulic system, it would surely be flushed out upon the subsequent bleeding...I'm not concerned in the least!

See also: https://www.sw-em.com/anti_seize.htm#More_Anti_Seize_Application_Notes

-----------------------------

Special Tools for Tubing: When working on Brake (or even Clutch) tubing, where fittings may be corroded and require maximum loosening torque, using ordinary open end wrenches increases the possibility of rounding off the hex, since the wrench only contacts two flats (and can/might even splay open slightly increasing the risk). Rounding off the hex can tremendously increase the scope of the job (and amount and volume of "colorful language" in the garage)...

Brake Fitting after being attacked (probably unsuccessfully!) with an open-end

wrench.

This is where using special wrenches can really help. "Flare Nut Wrenches" shown below, have an advantage over the simple open end wrench. They greatly reduce the likelihood of rounding the hex flats. The simple style shown on the left works by contacting five flats, a great improvement, but still being open, there is still some risk of the wrench and operator not having success, so rounding the over-nut fitting remains...the wrench on the right is optimal as it opens to allow installing on tubing, then locks closed to prevent splaying open, and acts on all six flats of a fitting. It also ratchets in the off-direction, helping in tight spaces...the major advantage is being able to be placed onto a tubing fitting, and still acting on all six hex faces! Always apply Anti-Seize, and use a wrench which acts upon the most flats of the fitting!

Tubing wrench variations. A simple version on left (the first one of these

was probably made when a

creative mechanic sawed a tubing clearance slot into a "Box-End" wrench), and on

right, a more advanced version which opens, locks closed and even ratchets in

the off direction!

Still more variations exist!

-----------------------------

Many have heard of this phenomenon...some may have even needed to deal with it, so pictures are included here. Symptoms are wheel components (either Calipers or Wheel Cylinders), which remain activated, and making friction even after the Pedal is released, resulting in sluggish performance, the vehicle possibly pulling to one side, steaming hot Discs or Drums (if one insists on continuing to drive), that only release after the corresponding Bleeding Nipple is opened momentarily to release pressure at that corner (another good reason to carry a 7/16" wrench in the On-Board Tools and Spares!)...which doesn't help much, because the issue might very well return next time the Brakes are applied! ...but at least one can limp home using the Handbrake...and leaving the Footbrake only for emergency stops (this makes the point for always having a well functioning and adjusted Handbrake, and Emergency Flasher!).

Following are pictures of rubber brakelines from a system which exhibited such symptoms, and which was cured of the symptoms after replacement of the lines. Thanks to Olli B. of the Volvoniacs Forum for the pictures. As one can see, passage is quite small to begin with, so there doesn't need to be much internal swelling to occlude the line totally...and since the cross-sectional area is a fraction of an inch, the high pressure occurring in the line during Pedal application is enough to overcome the occlusion, but the few PSI necessary to hold the shoes/pads applied after Pedal is released are not...the occlusion acts as a one-way Valve!

Link to Volvoniacs thread (German): Hintere Bremse geht fest (Rear Brake holds): http://www.networksvolvoniacs.org/index.php/Spezial:AWCforum/st/id7305/#post_50905

Rubber brakeline with two IDs?...no, one normal, one internally swollen to

decrease ID!

This line was on a 122 from 68/69 production, so the line was probably original

to the vehicle.

Notice "68 SAE" on the line. Olli reports the lines are from OE brake

component supplier: ATE,

from other identifying marks on the lines.

Also: My response to a

![]() thread, where

swollen brakelines on an ES are likely causing inability to make pressure at the

Wheel cylinders for the purpose of bleeding: "I

am not able to bleed the line: with line open at the rear, I get solid back

pressure on the brake pedal."

[...normally it just acts as a one-way valve, but I guess if you let the swollen

Brakeline reach its ultimate condition, it completely closes off the line.]

thread, where

swollen brakelines on an ES are likely causing inability to make pressure at the

Wheel cylinders for the purpose of bleeding: "I

am not able to bleed the line: with line open at the rear, I get solid back

pressure on the brake pedal."

[...normally it just acts as a one-way valve, but I guess if you let the swollen

Brakeline reach its ultimate condition, it completely closes off the line.]

"As others have pointed out...the flex-line swelling shut is a well known, common issue, and if you are replacing one, you should just go ahead and replace them all...they are all likely the same age and if not already collapsed/swollen shut, the others are well on their way toward this condition... I wont use rubber any more because of this, but Stainless covered Teflon instead, which does not do this stupid trick, and is therefore, forever!...and while you're in the process of replacing flex-lines, inspect all your hard-lines (especially under clamps) and if any need replacing, do this with the non-corroding CuNiFer lines...using Anti-Seize during installation of course. Sorry for the "Mission Creep" here, but sometimes, it really is the best...if it was me...I'd continue with the Mission Creep, and change over to DOT5 silicon Fluid, since you've done the Master already...I just took a so equipped Amazon out of looooong-term storage, and the brakes worked like the day it was parked!

Edit: Tip: Remember when bleeding dual Brk Systems the Brk Failure Valve, to REMOVE the Mechanical Grounding Switch from Valve BEFORE bleeding, so that the plastic pin does not get partially sheared off as shuttle moves during bleeding. Replace when bleeding operation is completed. See also: https://www.sw-em.com/Two_Wrongs_Make_a_Right!.htm... "

-----------------------------

Unacceptable Replacement Lines!

As also seen in the graphic above, I've seen replacement lines with preinstalled fittings which have the correct thread, but also an extended unthreaded section at the end. Where the Original Equipment lines engage the threads fully, as shown below, the replacement fittings do not. This means that on the replacement fitting, only a very limited number engage...this is unacceptable to me and I don't use these as delivered.

Know your Replacement Brake Lines and Fittings!

Finding the replacement fittings unusable as delivered, I have cut the unthreaded section off the replacement fitting, and used it, after being so modified, when an OE fitting was not available. When doing this, it is crucial to assure the cut is perfectly square to the fitting, and also 45º internally chamfered, as it must press the flare into its seat precisely! Modifying brake fittings is not for everyone!

-----------------------------

Answer to FB posting: Does anyone know a way to identify the size of the brake cylinders on the rear drum brakes without pulling the drums? Is there just a universal rebuild kit available from someone?

"Rebuild kits are unique to 3/4" or 13/16" bores...so if you're not sure (and who would be after 50 years, unless you're name is Irv G), buy both and return the one you don't use...but if you see severe pitting or scratches in bore, replacing Wheel Cylinder is a good idea although they can be honed if damage is only minimal. Remember, if you need to replace Wheel Cylinder, measure length of and buy hard brakeline to have on hand, because you may very well twist off line when loosening overnut, due to corrosion. Thread sizes are NOT American, or metric(!)..ask for British! (Color coded Red by some suppliers.) Before installation, be ABSOLUTELY CERTAIN that overnut thread, length and flaretype match and are correct!!! See: Brake Plumbing and Fittings for details. Good Hunting! "

-----------------------------

Front Shoe, Rear Shoe...and Brake Shoe Friction Contribution

Volvo rear Drum Brakes are a Simplex, Single Leading Shoe (SLS), modified design. In the left diagram below, the Standard Simplex Brake arrangement is shown, along with Relative Braking Force contributed by the Leading and Trailing Shoes. It can be seen that the Leading Shoe contributes most of the Braking Force, because of the "self-applying" characteristic. See reference: https://en.wikipedia.org/wiki/Drum_brake#Self-applying_characteristic

In the modified Volvo variation of the Simplex design on right, Leading Edge of Leading Shoe has been cropped, in order to decrease the relative percentage of Braking force contributed by this shoe, evening the Braking Force contribution (and friction material wear) between both shoes.

The Adjuster allows for reducing lost motion of the mechanism as friction material wears, and/but does not significantly affect relative Brake Shoe Contribution. See also: https://www.sw-em.com/Manual_Rear_Drum_Brake_Adjuster_Notes.htm

Volvo's modified version of the Simplex Drum Brake design, with Leading Brake

Shoe cropped and Adjuster .

Common saying: "The shoe is on the other foot." Volvo saying: "The short shoe is the leading shoe."

-----------------------------

Discovery: Mismatched Threads on All Amazon Braking Systems with Hydraulic Brake Light Switches(!), [from the factory no less!!] ...this was apparently standard practice, so it calls for extra care when replacing Hydraulic Brake Light Switch!

Oct 2022 R. Kwas

Explanation of an interesting finding follows! This came up in a simple question about the threads of the Hydr Brk Lt Sw...and I found it quite unusual and certainly interesting enough to investigate and document here.

My response to a

![]() question by

Andrew N. of "...[hydr] brake

light switch threads? 1/8” NPT?"

question by

Andrew N. of "...[hydr] brake

light switch threads? 1/8” NPT?"

"...the OE hydraulic pressure sensing Brake Light Switch located on the brass Brake Junction Block, I have found its threads [of the brass Junction Block] to be 3/8" - 24TPI, same as all the other brake lines, fittings, and components, but after so many years, and often unknown service and replacements, I advise triple-checking to confirm!"

Close-ups of Brake Junction Block, and Plug which replaced the hydraulic

pressure sensing Brake Light Switch no longer fitted on the later

chassis. Also shown is a thread gauge to confirm the thread pitch on the

Plug. This means that the when the Plug is fitted, it must be fitted with

a thread sealant!

...but that begs the question: How does the Switch, which we believe to have a 1/8" NPT (tapered pipe thread) fit here?

Then I posted this, before checking the threads on an actual Sw:

"...the Switch...may very well be a tapered NPT into the straight cut hole, and that would certainly address sealing requirement...but I also have taken a straight 3/8" - 24TPI Plug (without sealing washer) out...confirmed a factory fitted Plug...so I expect it had to be sealed in place with a sealant. The question to be answered is: Is the thread of a 1/8NPT also 24TPI?...and according to Gargle it is 27TPI!" [That sure peaked my curiosity!]

The Hydraulic Brake Light Sw thread

(Bosch Sw) clearly has an NPT (pipe thread, also confirmed with the thread gauge

to be 27TPI). Tapered NPT threads are

verified on Sw, by inspection, and comparing Plug and Sw threads confirm the

mismatch (if the Sw looks unusual to the reader, it is a failed Bosch part cut open for

inspection, and which was the subject of the failure study documented here:

Hydraulic Brake Light Switch Failure Investigation ).

Additional info I added to the

![]() thread after

checking the Sw thread:

thread after

checking the Sw thread:

See close-up pic where I can verify plug is 3/8"24TPI straight-cut, shorter than the hole is deep, so it shows no sign of having bottomed out in the hole to seal (which would have blocked the fluid passageway anyway)

"...the Plug is threaded 3/8" 24 (as is the Junction Block), and the Hyd Sw (OE Bosch) is indeed threaded 1/8" NPT (in other words 27TPI!).. so threaded into the JB, it would interfere...and indeed, I was able to thread the Plug in fully, by hand and without interference, but the Sw in only 2 1/2 turns by hand until significant interference occurs, to the point of jamming. [I guess that would seal too!?!]

Bottom line: The Hyd Sw seals into the brass threads, not because of the increasing diameter from the pipe thread, but because the threads jam!!!

The Sw threads into brass Junction Block 2 1/2 turns before thread interference

jams them tight. Lesson to be learned from this is to tighten with feeling

after that when installing! Some thread sealant couldn't hurt here

either...!

So my tips out of this are: When fitting the Plug, seal it with a thread sealer, and when fitting Hyd Brk Lt Sw, also use sealer and "Feeling" and DO NOT OVERTIGHTEN!

Note to self: Check the "learned something new today" box on calendar!"

...and somewhat unexpected...and this qualifies!

Repeating my advice from above (Brake Plumbing and Fittings), to all mechanics working on the vintage Volvo brakes: Triple check EVERYTHING!

------------------------------

Rebuilding Calipers:

Girling 3 Piston Caliper Rebuild Tech Article

-----------------------------

Excerpt from a

![]() asking: "Has anyone converted their rear drums to rear disc brakes? I have a 1969.[1800]"

asking: "Has anyone converted their rear drums to rear disc brakes? I have a 1969.[1800]"

My response: "

Link to: AC Cobra Brakes

-----------------------------

Brake Drum Removal, Inspection, Reassembly Notes

Manual Rear Drum Brake Adjuster and Adjustment Notes

Link to thread: Not Matching Brake Shoes http://www.volvoforums.org.uk/showthread.php?p=2273070#post2273070

4 PISTON Girling calipers for Volvo P1800/122 [120-130] [1965] http://www.brickboard.com/RWD/index.htm?id=681534

Kwik Tite Wrench video: https://www.youtube.com/watch?v=GyNvPpzXJm0

Good Reading on Brakes by an MG specialist:

http://www.mgb-stuff.org.uk/braketext.htm

Brake Fluid Level Monitor:

http://www.mgb-stuff.org.uk/bflevel.htm

-----------------------------

Link to a very good presentation showing theory of operation and function, as well as rebuilding details and advice.

https://www.youtube.com/watch?v=quRJ4_sqMYU

My response to a thread on Girling Brake Servos:

https://forums.swedespeed.com/showthread.php?621257-Brake-Booster-Servo&p=7582725#post7582725

"...I have been told that if I don't rebuild, replace or remove it, I will suffer a catastrophic failure."

My Response: "I guess you might call the Pedal going to the floor, and

expelling a huge cloud of white smoke out the exhaust "catastrophic

failure"...that's what happened to mine...it does put one at a "state of

increased awareness"!

Rebuilding a Girling brake servo is quite tricky and some who have tried it, and

missed some of the important areas, had less than satisfactory results, with

non-linear assist or grabbing once reinstalled or other unusual symptoms...I

understand the condition of the inner diameter of the vacuum vessel is (just)

one of the critical areas...if pitted, so that it doesn't interface well with

the leather seal on the piston, that it is two and a half strikes against

possible rebuild success, unless you can plate or somehow restore the

surface...then there are the hydraulics...

I've never attempted rebuilding one...I just use the strongleg technique on my

brake pedal...

This excellent Jerry Christopherson (from the Sunbeam Tiger world) video covers

theory of operation details, as well as rebuilding details, specific areas to

note, and special tools and techniques for rebuilding...it is required viewing

if you are considering trying your hand at it, or even just want to know how the

unit is supposed to function...: "

---

My ![]() response to

"What are the symptoms of a failing booster?"

response to

"What are the symptoms of a failing booster?"

Slow Failure Mode: Slow decrease of fluid

level in reservoir with no obvious/[or

even apparent] leaks, but at a rate faster than could be explained by pad

usage (Brk fluid is going into vacuum chamber!).

Sudden Failure Mode: Sudden low

pedal resistance on braking (like a system leak, which it is! Little or no

Hydraulic Brakes, and needing to use the E-Brake...which makes the point well

for ALWAYS having the E-Brake properly adjusted and AVAILABLE! ) accompanied by

engine consumption of brake fluid with a massive Goldfinger-like smoke screen

from exhaust. ...no fun, and will get your full attention every time!...also a

good reason to occasionally practice emergency stops with Handbrake ONLY!

My Response to a ![]() comment questioning how an Amazon without a Brake Vacuum Assist unit is capable

of stopping "Where

is the brake booster. How does this thing stop ??"

[It's a Vacuum Assist unit, or Brake

Servo, which amplifies the Pedal input a bit, not to be mistaken with Power

Brakes, which amplifies the Pedal input a lot!]:

comment questioning how an Amazon without a Brake Vacuum Assist unit is capable

of stopping "Where

is the brake booster. How does this thing stop ??"

[It's a Vacuum Assist unit, or Brake

Servo, which amplifies the Pedal input a bit, not to be mistaken with Power

Brakes, which amplifies the Pedal input a lot!]:

They stop just fine without a Vacuum Assist unit! ...what you're complaining about is the amount of effort required...especially if you're accustomed to modern cars with fully assisted Brakes and Steering, and that's what you expect of an Amazon also...sorry! Modern cars are designed and built to be able to be driven by 90Lb weaklings or frail grandmas. An Amazon is made to be DRIVEN, which includes requiring some INPUT to Steering and Brakes! If you expect it to drive with as little or no effort as your Honda Accord, you're in the wrong place, bud!

-----------------------------

Reference Information:

Red Rubber Grease: As it has no author or commercial parties taking responsibility for content, I can't quite figure out if the http://www.redrubbergrease.com/ homepage is some enthusiast individual's, or the least slickest (no pun intended!) commercial homepage ever published, but it has good reference info, useful for when working on vintage Volvo brake plumbing, or even components of the hydraulic Clutch! The page doesn't really try to sell anything, but it is a good practical collection of the uses and benefits of RRG:

------

German Brake component manufacturer ATE has a (transparent, not red) equivalent product, compatible with non-silicon based brake fluids: http://www.ate.de/media/2317/technical_datasheet_brake_cylinder_paste.pdf

-----------------------------

CuNiFer Brakeline: [I'll not be using steel brakeline ever again!]

Good info: http://www.brakeconnect.com/cunifer-brake-line

Brake Connect / XXXXX Clarksville, Tenn. Mr. Jason Landrum, Owner

Copied from there: My Highlights

Cunifer Brake Line

CUNIFER

The new ‘old’ material for brake lines

Last month I mentioned a `new’ product that has been around for years – only nobody knew about it. It is a material known as Cunifer – an alloy of copper and nickel with a bit of iron and manganese thrown in for good measure.

In the world of metallurgy, this material goes by the names of

Copper-Nickel CA 706, Cupro Nickel 10%, and C70600 and, as mentioned

Cunifer alloy. In actuality,

the alloy consists of 88.7% cop-per

(Cu), 10% nickel (NI) and 1.3% iron (Fe ),although I have seen

specifications listing 0.8/0 manganese (Mn).

For those of you who are not chemists or metallurgists, the previous paragraph was probably wasted, but it is important in that this special alloy makes a wonderful substitute for the traditional steel brake tubes used on our cars.

Let’s step back seventy or eighty years to the 1920s. Of course most automotive brake systems of the time were mechanical, but hydraulic systems were beginning to make their appearance. The lines used to carry the hydraulic brake fluid were generally either copper or brass (a copper/zinc alloy). These lines were strong and easy to work with – they could readily be bent, flared, soft-soldered or brazed.

In the 1930s it was realized that both copper and brass had a tendency to work harden (more on that below) making the metal structurally unsafe for an automotive component on which your life depended. Steel lines were substituted on brake systems. They were strong and did not work harden, but they were difficult to work with, unless one had special equipment not normally available to the hobbyist. Besides being difficult to bend to fit, steel lines were extremely susceptible to corrosion. Salt and other chemicals used on the roads to melt ice and snow played havoc with steel. The reaction was to coat the steel with a corrosion resistant material. Over the years tern (a lead-tin alloy), zinc and epoxies were tied, with more or less success. Their biggest drawbacks were that all of the coatings were susceptible to damage from stones and other road debris and to scratching of the surface when working on the car. Once the coating was breached, it was like working with uncoated steel. The second problem (and one not generally addressed by those making the determination of choice of materials) was internal corrosion. We know that brake fluid – DOT 3 or 4 will absorb ambient moisture and hold it in suspension within the hydraulic system allowing it to do its insidious thing within our brake lines. I have been told by brake specialists that more line corrosion occurs from within the brake tubes than from without.

When this corrosion occurs, the lines leak and the brakes fail. It’s that simple. The dual brake system provides a back-up, but it’s not the answer. Replacing the brake lines is really the only way to go. Once corrosion has shown up in one line, you can be sure that it’s happening elsewhere in the system. For us it has meant putting the car out of service while the entire system is replaced – either in a professional shop or in our garages. The rotted steel lines are generally replaced with brand new pre-measured steel lines available from our local parts store. Since these lines come with fittings already installed, we have to work with what they sell us. Overly long lines can be ‘looped’ to take up slack, but bending steel lines, especially tight bends, often results in kinked lines that are suitable only as trash. Very few of us have the equipment to double flare a steel brake line, and often, if our wallets are fast enough, we can purchase complete brake lines all bent and shaped to fit our particular model or car.

In the 1970s the Swedish automobile regulators realized that the high degree of corrosion was downright dangerous. All kinds of studies were done (no, I won’t bore you with statistics) and a new material was tried: Cunifer

This alloy provided superior corrosion resistance to steel, was malleable, easy to work with and easy to flare, was strong and had most of the benefits of copper tubing without the liability of work hardening. The inclusion of the nickel, steel and manganese made it stronger than copper alone, but still short of the strength of steel. The Cupronickel alloy is softer than steel and so more subject to damage from rocks and stones being kicked up from the road than steel. Fortunately it is a rather easy problem to fix. A special protective shield – in fact, a stainless steel spring – fits over the metal brake line at points of exposure to road hazard Where the line goes through the frame of the car, or is protected by the frame, this is not necessary. Brakes lines (rigid brake lines as opposed to flexible rubber lines) do not have specific testing requirements, but tests on the C70600 material have shown it to be more than adequate for our needs. More on that and more on governmental regulations in a few paragraphs

The Swedish car manufacturer, Volvo, began using the 90/10 alloy for brake lines in 1976 and they began tracking brake failures based on eight-year old Volvos. Brake failures dropped markedly once this new material was used. [Volvo leads the way again!] In subsequent years, other manufacturers in Europe have begun the switch to Copper-nickel from steel lines, and currently Rolls-Royce, Aston- Martin, Porsche, Audi and, of course ‘Volvo, are using this material in their new car production.

The bar graph above depicts the percentage of vehicles falling safety Inspections because of defects in the brake systems of eight year old Volvo passenger cars. The 1970 model cars had tern-coated steel tubes. 1971 models had zince coated steel tubes. 1976 models used copper-nickel tubes. The reduction in defects is dramatic.

Why, then, are U.S. manufacturers not using Cunifer rather than steel for brake lines? The most obvious answer is cost. Steel is still considerably less expensive than Cupra-Nickel 90-10, and at the manufacturing level with everything highly auto mated, the problems of bending and flaring don’t present problems. “But,” you ask, “what about DOT and SAE approval? a very good question Ready for this. At the present time DOT does not have any regulations covering rigid brake lines. They do for flexible lines, but not for the rigid metal ones. In the typical `government-speak’ that seems to be the written language of all governmental agencies, we were advised that, “NHTSA (National Highway Traffic Safety Administration – a division of Department of Transportation) has brake hose standards for flexible’ hoses only (and more recently for plastic hoses too). But there is no federal standard for ‘metal’ tubing. That said, that doesn’t mean that defective metal tubes can be used in braking systems because if they fail due to a defect (corrosion, bursting, etc.) then that is a defect and a violation of the ,government’s motor vehicle safety statutes.” Follow that? In other words, if it works, its fine, but if it fails then it’s defective and not okay. And the Society of Automotive Engineers (SAE): “SAE does not ‘approve’ products. We are a standards organization; therefore we create standards for the auto motive industry that are voluntary. We do not require they be used.”

Let’s get back to our needs then. So C70600 is acceptable for hydraulic brake lines. There is one factor that we do have to consider though when deciding to rip out that brand-new steel system that we just installed and replace it with Copper-nickel. We don’t (generally) use our old, collectible cars on icy, snowy, salt-encrusted roads. The cars are tucked away for the winter in a nice, warm, preferably heated garage, up on blocks or jack stands. But while we’re sitting in front of a nice warm fire, the moisture in the brake fluid is working at the inside of the steel tubing. The outside may be coated with tern or epoxy, but not the inside. Maybe, when you completely re-did your brakes you used Silicon (DOT 5) brake fluid. Then relax and pour yourself another hot toddy. Your brake system is okay. DOT 5 does not absorb water.

I sure took a long way around to get here but the bottom line is that it looks like Copper-nickel tubing is perfectly acceptable and more than adequate for our brake systems. It’s strong, corrosion resistant, easy to work, remains pliable, and can be readily flared (or even soldered or brazed). I’m going to hedge a little bit here. Although 90-10 doesn’t work harden as readily as copper alone, it does get stiffer as it is bent. Three or four bends and it is not nearly as flexible as it was to start. But realistically that shouldn’t be a problem, because if you have to bend and re bend and again re bend a section of brake line when installing it, then maybe you should let a professional do your brakes.

Two last points. Stainless steel brake lines provide the strength, durability, corrosion resistance and appearance for an excellent brake job. But Stainless is not a material for the home hobbyist to work. You can buy pre-formed, pre-bent brake lines to fit your particular car, and it’s an easy bolt-together project. But it is not cheap!

Next, what does Copper-nickel look like? Well, if you leave it alone, it looks like and colors like copper. That’s great for an authentic looking restoration. But if you polish it, it will take on an extremely bright copper gleam. If that’s what you want.

The question now comes up, “Where can I buy this miracle product?” Fortunately, that’s an easy one. I was recently speaking with a well-known restoration shop manager and we were discussing Cunifer. He knew what it was right away, and told me that he had a coil of it squirreled away in a back room – stuff he had ordered from Europe.

You don’t have to go to that trouble. Brake and Equipment (see ad on page 48) stocks it in a variety of ‘diameters and will sell it by the foot. So if you need 27 feet of it you can buy 27 feet. You don’t have to buy two 25 foot coils and let the remainder sit on a shelf, nor do you have to buy two ten foot lengths, two three foot lengths and a fifteen inch length and

How Did We ‘Rediscover’ Cunifer? As we indicated Cunifer brake lines are not new. They have been used in Europe, especially in England for many years. But they are ‘new’ to the United States. Why and how did we happen to rediscover this product?

Perhaps we get into a rut; we get used to doing something one way, and it’s just too much trouble to change. Or maybe, despite superb international communications, we are a little lax in getting information from ‘the old country’. But whatever the reason, copper-nickel brake lines have been in use in England, Australia and more than likely in other countries with a heavy British influence.

Fred Anderson, an American citizen raised and educated in Australia, recently moved to the United States from the Sydney area and wondered why we weren’t using Cunifer here as he had been doing in Australia.

Without belaboring the background research that Mr. Anderson did, he determined that there was, in fact, one other source of Cunifer brake tubing here in the U.S., but that company was purchasing its brake tubing from England. With the extremely unfavorable monetary exchange rate, freight, duties, etc. this material was quite expensive when resold to the U.S. buyer.

Fred’s newly-founded company – about five years old, Brake Quip out of Tennessee contracted with a major manufacturer of tubing to make the Nickel-Copper lron alloy for him, to his thin-walled specifications. Today Brake Quip is the only company manufacturing Cunifer brake tubing in the United States for the aftermarket, and it is selling it through its distributors at prices highly competitive with steel lines.

“It was a matter of recognizing a void in the market and doing the legwork to fill that void” reports Mr. Anderson. “We found one of the best companies in the country to make C70600 (Copper-Nickel) tubing to our high specifications. That product, in conjunction with our line of specialized brake fittings, installation equipment then bend it to fit as you do with over-the-counter pre‑formed brake lines. You can buy just what you need, flare it yourself and install it as easily as you would regular copper line. When you buy it though make sure that you order the correct fittings for brakes. They ARE NOT the same as the plumbing fittings that you buy at the local home building center. Brake fittings require special flares at the ends. Compression fittings are NOT acceptable, nor are single flares. A double flare is much stronger than a single flare, and is not a lot more difficult to make.

Next month we will discuss how to make a double flare, why they are necessary and the tools that are needed to make a good, strong double flare and flex-lines made us a natural source for the brake industry. We don’t sell anything at retail; everything that we manufacture, or have manufactured to our specifications is sold to or through nationwide distributors, o f whom, Brake and Equipment in Minneapolis is one of the largest.”

Well, that’s how the product came to the United States, but what brought it to the attention of Skinned Knuckles? Brake and Equipment wanted a larger display ad and that led to a discussion of what a larger ad should contain. Jim Terrell of Brake and Equipment was very high on their new product, Ezi-Bend, a copper-based brake line with which they have been extremely successful.

We talked about the inherent problem of work hardening of copper, but Jim assured us that they haven’t found that to be a factor. We discussed the ease of working Cunifer; whether it was suitable for the home hobbyist and whether it could be double-flared, an important consideration in making hydraulic brake lines. From there we went directly to the manufacturer, Brake Quip, and got their input on the product. Not willing to accept anyone’s word that Cunifer was acceptable under the regulations formulated and administered by both SAE (Society of Automotive Engineers) and DOT (Department o Transportation [National Highway Safety Administration within the DOT actually)), we contacted both organizations.

We also attempted to contact Volvo, Audi, Rolls- Royce and Porsche to confirm that they were indeed using Copper-Nickel brake lines. So far, we have not been very successful in getting a response directly from these OEM sources, but we’re still trying.

Bottom line, though, is we have uncovered a product that could, should and I expect, will be an important part of future restorations. We would be very interested in hearing of your personal experiences with this product. Let us know how your brake restoration projects progress using Cunifer.

It may be hard to believe but it’s so easy to bend duplicating your existing line is borderline fun. Replace your brake line with Cunifer Tube and never do it again.

-----------------------------

Incorrect Assembly of Rear (Drum) Brakes on 122 and 1800 Vehicles causes Risk of Handbrake Failure.

The info here should be nothing new to Volvo experienced mechanics...it is more directed to helping first-timers or even owners who don't work on their Brakes too often, with the intent that they don't repeat the minor oversight documented here, and that they assemble their rear Brakes right!

When a new 1800 owner found his Handbrake not applying any braking action on one side, he posted to the Swedespeed forum looking for advice. Naturally, the first suspects were the Cable and associated installation on that side, but everything seemed normal...the Cable was being actuated by the Handbrake, and not damaged or frozen, and the Cable was being pulled back after actuation, confirming action of the Return Spring!

Read the entire Swedespeed thread here: https://www.swedespeed.com/threads/hand-brake-problem.653779/

Normal pedal brakes also functioned without issue...only Handbrake failure on one side was the extent of the failure symptoms. The Drum had to come off for a detailed inspection of the mechanism and interface with Brakeshoes. What Charlie found was is documented here, and I did figure this incident was important enough to document the root cause and correction, as the reassembly when doing a rear brake service is possible to be done incorrectly since it is not a poka-yoke design. Poka-Yoke/error-proofing is a nod to Shigeo Shingo, Japanese Industrial Design Engineer the 1960s, responsible for the Toyota Production System. [I guess he came just a bit later than when the rear brakes of the 122 were designed!]

Charlie Mayne pictures reposted with his kind permission. ...and thank you also to Charlie for allowing it to be documented here, most certainly not for the purpose of humiliating anyone [Let those without sin cast the first stone!], but for the purpose of helping other assemblers avoid the same mistake on their brakes!

Issue which causes loss of Handbrake function:

Rightside Rear Brakes.

Handbrake Lever pivot pin has come

dislodged and out of its place in the Brakeshoe! Loosing the

fulcrum for the Handbrake Lever causes Brakecable motion not to be translated into separation of the Brakeshoes,

resulting in failure of function of Handbrake on that (in

this case, right) side of

vehicle. Notice the Curved

Feature of Crosslink is visible.

The root cause of the issue is clearly visible in the picture above...by assembling the Crosslink with the Curved Feature on the outside, where it is visible, the feature cannot do its intended job of keeping the pivot pin located in the Handbrake Lever. In earlier versions (see: Factory Exploded Assembly Diagram Markup below), the pivot was a separate item, with a securing clip, but on all Handbrake Levers I've ever seen, the pin is a permanent part of the Handbrake Lever, with no additional Securing Clip present.

In this picture of the other (left) side, the Curved Feature is not visible, so it is clearly behind the Brakeshoe and correctly assembled.

Picture of Brake assembly on Left side of vehicle for reference. Handbrake

Lever is in proper position, and all looks (and functions) well!

Notice: Curved Feature of Crosslink is not visible.

Back to the right side...Handbrake Lever pivot has been repositioned in

proper position, and will

stay there(!), because the Crosslink between Shoes has been turned

up-side-down from its previous incorrect position, and the

Curved Feature placed behind Brakeshoe! It

is the Curved Feature which positively prevents the Handbrake Lever pivot from

popping out of place.

While style and position of the Brakeshoe Cross-link is a minor but clearly important thing, and not immediately obvious to the uninitiated, the manuals touch on it only indirectly, so they are not of much help. From the Volvo Green book: "...handbrake link in position, ensuring that it is turned correctly."...from Haynes: "...handbrake link in position and make sure that it is turned the right way".

[Clearly the Haynes Manual simply paraphrases the factory manual! If I had been writing the manuals, I would have added "...with Crosslink Curved Feature on Handbrake Lever side and behind Brakeshoe.", which would be the correct and unmistakable interpretation of "turned correctly", or "right way", and which would also assure correct assembly... ]

Factory Exploded Assembly Diagram Markup for Rear Brakes

Exploded assembly diagram showing A loose Pivot Pin (8) which

must be assembled into Handbrake Lever (7) and secured with clip (9), behind the

(trailing) Brakeshoe. I have added the more common version

at B, with Pivot Pin

as a permanent part of the Handbrake Lever, not needing a retention clip, BUT

paired with the extended Crosslink (10), with the

Curved Feature for

keeping the assembly in place. The Curved Feature must be on the Handbrake

Lever side, AND behind the Brakeshoe.

Comparison Pictures:

Chris Horn has once again been able to provide reference pictures...this time of both styles of Crosslinks, from his vast collection of used parts, ready to serve in active duty again. He does note: "I’ve got lots with the hooked end, looked for awhile before I found a flat one."

The observant viewer may notice the

double-wide slot on the right side in the early Crosslink shown here, and

the stepped slot, also wider, in

the later Crosslink. The slot is wider to accommodate both Handbrake Lever

and Brakeshoe backbone.

-----------------------------

Chicken-guano in DOT4 filled systems?

Eyal M. pic used with his kind permission.

My response to a ![]() question and comment to the above picture...and about that crystalline material

occurring on a Brake Booster Vacuum Filter: "....Was this car dragged out

of a medieval chicken coupe sitting under 40ft of a Swedish glacier?"

question and comment to the above picture...and about that crystalline material

occurring on a Brake Booster Vacuum Filter: "....Was this car dragged out

of a medieval chicken coupe sitting under 40ft of a Swedish glacier?"

" That chicken-guano is simply what DOT4 brake fluid seems to turn into when in contact with the alu casting and also exposed to moisture...I would say a small amount leaked from the plumbing of the vac assist unit with this result...it is often found in clutch reservoirs where fluid hasn't been changed in ages!...but it doesn't seem to occur as much in the steel Brake reservoir [likely having something to do with the higher level of chemical reactivity of the alu the fluid is on...]...so much for my scientific study of those dilythium crystals !

The crystals are soft, so it seems to be harmless in that it doesn't hurt the metal and can be cleaned off and alls well...since it is a deterioration of the fluid, it does not occur when using DOT5 silicon...maybe another reason to switch to DOT5! Cheers

-----------------------------

Additional (almost important) Information:

ABS: I love a good metaphor or analogy (as readers of my tech notes and articles may have noticed!) ...so when I saw this, I laughed so hard, I almost spilled my adult beverage!

-----------------------------

External sources attributed. Otherwise this information is Copyright © 2022. Ronald Kwas. The terms Volvo, Girling and ATE are used for reference only. I have no affiliation with any of these companies than to try to keep their products working for me, help other enthusiasts do the same, and also present my highly opinionated results of the use of their products here. The information presented comes from my own experience and carefully considered opinion, and can be used (or not!), or ridiculed and laughed at, or worshipped, at the readers discretion. Don't muck around with brakes if you don't know what you're doing! As with any recipe, your results may vary, and you are, and will always be, in charge of your own knuckles, and future!

You are welcome to use the information here in good health, and for your own non-commercial purposes, but if you reprint or otherwise republish this article, you must give credit to the author or link back to the SwEm site as the source. If you don’t, you’re just a lazy, scum sucking plagiarist, and the Boston Globe wants you! As always, if you can supply corrections, or additional objective information or experience, I will always consider it, and consider working it into the next revision of this article...along with likely the odd metaphor, or analogy (see: ABS!) and probably wise-a** comment.