Manifolding

Notes for B18/20 Motors.

R. Kwas Nov 2017 continuously update

[Comments added]

----------------------------------

Factory Manifolds

Non-Factory Configuration using Factory Manifolds

Dual Throttle Manifold

Non-Factory Manifolds

Links

Exhaust Manifold for Exhaust Gas Recirculation (California configuration)

Stepped Spacer /

Manifold Washer

Cracked Exhaust Manifold

Experience

----------------------------------

Volvo went through a number of Intake and Exhaust Manifold evolutions in the many years that the B18/20 were produced and installed into cars, not to mention boats. Each has it's reason for existing, and I've tried to collect pictures and descriptions of the various styles here to give an overview, plus touch on advantages and disadvantages. Approximate years of use and markets given refer to what is known to the author, based on what was delivered from the factory, which was market dependent. Non-factory Manifolds were also developed by second source suppliers to allow fitting single down-draft or side-draft carbs, and non-factory combinations of factory Manifolds are not uncommon. What one may find on a engine now, after such a long time, may certainly have been changed from what the factory delivered...

----------------------------------

One-piece cast, for a single down-draft carb (typically the Zenith VN36, for European delivery vehicles), with a 4-1 Manifold for Exhaust.

----------------------------------

Intake Manifold for single side-draft SU or ZS(gag!) . This would have been paired with a separate, cast, 4-1 Exhaust Manifold shown below.

Picture by Volvoniac M. Neuner, used with permission and thanks.

----------------------------------

Double sidedraft carb aluminum cast intake Manifold (as was typical for US delivery vehicles '66 and earlier). It would have also been paired with the separate, cast, 4-1 Exhaust Manifold shown below.

Note fastener holes of the throttle linkage bracket in-line* with balancing tube.

* See also below for a

better view of this!

----------------------------------

The 4-1 cast Exhaust Manifold:

This shop has Nickel plated the Exhaust Manifold casting.

----------------------------------

One-piece cast Iron Dual Intake, with 4-2-1 Exhaust Manifold (approximate years of use: '67-'68).

On what looks like a late B18 (Cast-in Alt pivot). Note angled

throttle linkage bracket at Orange and bolting flange for

Intake is equal in thickness to

Exhaust area, so a simple (thick) washer with a fastening loop for one end of the Throttle Return Springs

is used, hence the Loops at

Blues.

Picture source:

http://forums.turbobricks.com/archive/index.php/t-269326.html

Manifold Washer with Throttle Spring Loop (necessary for "Early 2-Air-Cleaner

Bolt" Carbs...later "3-Air-Cleaner-Bolt" Carbs have Return Springs captured on

throttle shafts and don't need the Throttle Spring Loop). It is extra thick because it

needs to bridge a gap between the two Manifolds.

When making non-factory combinations of Manifolds (particularly when installing

a Header, factory Intake Manifold, and "2-Bolt Carbs"), a step between Intake and Exhaust Manifolds

will occur. This

requires special attention to assure Manifolds are and stay securely

fastened! See also below.

----------------------------------

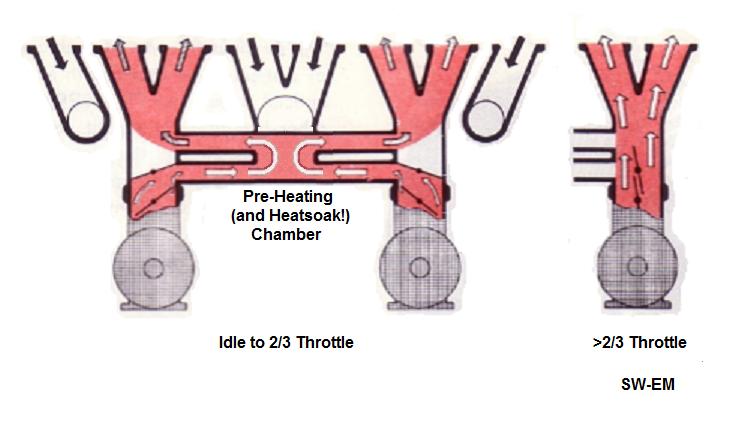

Dual Throttle Manifold (used '68-): This is the one to stay away from!

Massively heavy, many more places

for False Air to enter, puddling of fuel in the center Pre-Heating (and

Heat-Soak) Chamber, resulting in inconsistent idle, miserably poor starting after

Heat-Soak...if I thought about it, I could probably think of a few more reasons

not to use it because of that ridiculous Intake...however, it is paired

(literally...as a one-piece casting!) with a very good 4-2-1 cast Exhaust (...so

one can only imagine the horrendous thermal stresses it is therefore subjected

to!).

Mixture flow through the Dual-Throttle Manifold, intentionally picking up lots of

heat from the Exhaust in operation, and more during Hot-Soak.

The intake flow could only be more complicated, if it was by way of the

passenger compartment!

The best thing one can do is to simply cut the Exhausts off for use, and to just recycle that miserable Intake part (or to use it as an anchor for small watercraft)...or save the entire thing and bring it with you to the next Volvo-club get-together...a contest to see who can toss it the farthest is always a fun activity!

Link to Reference information.

Phil B has done such a manifold separating operation, and found that the original Throttle Linkage (specifically length of the last Ball-link had to be lengthened for the linkage geometry to work correctly. PLACEHOLDER FOR DETAILS

----------------------------------

Non-Factory Configuration using Factory Manifolds:

Intake: Early aluminum casting suitable for dual SU (or Zenith/Stromberg carburetors). A vacuum port used for PCV and/or Brake Assist Unit may be located in the center of the balancing tube, pointing up, OR longitudinally at the front, in-line with the balancing tube, facing forward.

This is probably everybody's (the author's too!) favorite setup! Early Aluminum Intake combined with later cast Iron 4-2-1 Exhaust from an injected setup. This combination, is the cleanest, best performing setup, with best longevity.

Separate Alu intake, and Iron 4-2-1

Exhaust.

Cool intake, and highest performance factory Exhaust. Here, mounted to an E Cylinder Head.

Note horizontal throttle linkage bracket mounts at Orange, in-line with balancing tube.

Note also that (CIS) injector ends are still in place at Blue...if a configuration such as this is to be used with carbs, Injectors are typically removed and those ports get blocked off. Source: http://www.turbobricks.com/forums/showthread.php?p=4580824

Combining that Exhaust Manifold with a stock Headpipe from an 1800E, which has a 2" outlet, and from there back, a custom Exhaust System is a good performance setup, with good longevity, and service with standard parts.

Standard 2 -1 headpipe.

----------------------------------

Intake Manifold for Single Down-draft Weber (DGEV)...a favorite of those who think they can bolt-on a tune-up!

This Manifold is plumbed to the Cooling System for preheating the mixture.

You can even install a Holley four barrel carb onto your B18/20. Picture

from an ebay offering.

----------------------------------

Dual Weber (Solex) Side-draft Manifolds:

Manifolding for dual side-draft (DCOE) Webers places the Intakes of the Carbs quite close to the inner fender, leaving little room for Air Filters. Below, installer only has installed shorty stacks.

Support (not visible below) in addition to the Manifold, for the overhanging mass of side-draft carbs, is highly recommended!

Dual Weber DCOEs with stubby stacks, because there is little room for proper Air

Filters.

Selecting Air Filters which include little tilt-up runners to locate the filters up and away from the inner fender, is an option.

Dual Weber DCOEs with Air Filters.

Intakes for Weber DCOEs by TWM are two separate castings.

A one-piece casting with a connecting brace, in the Mangoletsi version (bottom

view!)

Stiffening spines are cast into this version (Manuf.?), where they are also

separate. These are the ones supplied by Volvo with the Competition

Service (Solex) kits, and are the only style the author would install without additional

support for the overhanging mass of the carbs.

I expect these very long (SPR) manifolds for Weber DCOEs, would put the intakes

of the carbs into the Wheelwell of a streetcar,

to say nothing of where that would put Air Filters......I'd like to see Carbs

mounted on them and a measurement...!

I expect this arrangement is only suitable for race cars with purpose-built

engine compartments.

Note: At the (injected) Cylinder Head above, additional holes for Injector Mounts are evident at Yellow, and holes into ports themselves appear to have been blocked by some means not possible to make out under the nice, shiny new paint. Holes for Auxiliary Air Valve at Blue are also missing or blocked...OR...this was one of the FI blank Cyl Heads delivered by Volvo Competition Service (VCS), intended for carbs, where those holes were not machined in the first place.

Pix of a very nice Air-Filter clearance bump-out (there's plenty of room over

the A-Arm of the suspension under there!),

including an in-progress picture, by Chris Ceihagen, and used with his kind permission.

---------------

Maybe a single Weber or Solex is enough for you!

Here are some variations for mounting a single Weber or Solex sidedraught carb:

Single DCOE Weber on a Volvo engine...note how close to the inner fender, the

end of carb is...

...there is not much room for and air filter!

------------------

Factory manifold vs. alternate manifold intake pulse sequence.

I noticed this difference, so was thinking about and somewhat intrigued, and

trying to understand the reasons for it...other than the very general statement

that they "tune" and optimize the Exhaust flow (with Manifolds, headers, etc),

which doesn't really explain this, it follows that similar tuning and

optimization can be done at the intake also. If there are any readers out

there who work in an engine dyne department or tuning field who see this and who

might offer a more specific explanation, the author invites them to send an

e-mail!

|

|

|

|

| OE manifold for dual carbs. | Manifold designer has cylinders 1 and 2, and 3 and 4 combined runners, similar to the oe Volvo Manifold. |

This manifold designer has a different sequence of Firing/Intake

Order. 1 and 3, and 2 and 4 are combined. |

|

Intake pulses at carb barrels would be unevenly spaced: 1--3-4--2-1--3-4--2... |

Pulses of vacuum at carb barrels will be evenly spaced: 1--3--4--2--1--3--4--2... |

|

----------------------------------

Since this is the highest performance setup, DCOE Weber carbs are typically paired with a tubular Header on the Exhaust. Clearance to Generator/Alternator can be close, but there is room. Below, examples of two difference setups with a header:

Delco Alternator on

SW-EM bracket

clears Header just fine.

Some of Phil Singher's fine work!

----------------------------------

Discussion on the subject: http://www.turbobricks.com/forums/showthread.php?t=278890

Injector Port Block-Offs (when using the good flowing Cylinder Heads intended for injection, but with Carbs): http://www.sw-em.com/swemkits.htm#Fuel%20Injector%20Port%20Blockoff

Exhaust Manifold for Exhaust Gas Recirculation (California configuration) [This Manifold could certainly have been shown here, but I located it on the Carburetor Additional page first, for its possible repurposing with Exhaust Gas Temperature (EGT) sensing or O2 sensing.]

----------------------------------

Related Information:

My response to thread: Split Exhaust Manifold "...mechanic advised ... "the exhaust pulse" is wrong", on Swedespeed Forum: http://forums.swedespeed.com/showthread.php?541074-Split-Exhaust-Manifold&p=6612882#post6612882

I think your mechanic is referring to the sequence and timing between exhaust pulses, as they hit the exhaust manifold and system downstream...ideally, as with headers, the equal length tubing causes them to be equally spaced and sequenced at the collector, so because of this equal length, and hopefully some length and frequency (aka RPM) tuning, this will lead to scavenging at the collector which would serve to help extract exhaust from other cylinders...for the 4 into 1 manifold, flowing through a stock exhaust system, there is so much flow restriction downstream anyway (even if you did have more than an A Cam), that worrying about it here is totally misplaced effort IMO...for the 4-2-1 manifold its a lot better, and the 2-1 pipe combines the flow far downstream of that (also with some scavenging effect), so that is the desirable exhaust manifold, but still nothing to worry too much about if you have a stock exhaust...if you need to wring the absolute most out of an engine, a much hotter cam, a ported head, a header, separate intake manifold, a much freer flowing Exhaust System, and hours on an engine dyne to optimize carbs, and ignition curve, are what you need!...if you are building a good roadcar (with bearable exhaust noise level), use the standard setups and don't let your mechanic friend make you crazy with details which are fun to discuss over a beer, but pretty much irrelevant unless you're on the racetrack...!

----------------------------------

Other Details:

Stepped Spacer / Manifold Washer:

Exhaust on this injected motor has been changed to a Header, resulting in a

large step from Intake Man. Flange to Exhaust Man. Flange. The

thickness difference is very apparent in this view.

A stepped spacer/manifold washer has

been manufactured and installed to accommodate the difference, and this allows the nut

to bear on a surface perpendicular to the fastener axis...the best, and a sharp

solution!

-----------------------

Cracked Exhaust Manifold Experience

Link to Brickboard Thread: SU Guru needed, Lean Stumble https://www.brickboard.com/RWD/index.htm?model=120-130 pictures reposted with kind permission of "TR Conn".

A cracked Exhaust Manifold, shown below, had symptoms of ticking and a "Lean Stumble" which owner mis-interpreted as Lifter noise..."there was noise, it was a ticking that sounded much like tappets. I adjusted them a couple of times but the clicking persisted." Try to listen and be aware of the noises (specially "new" ones!) your Volvo makes...it is talking to you! [Those ticking noises were likely pulses of exhaust escaping, and maybe even the noise of Exhaust Valves closing...perhaps the higher exhaust temps associated with a Lean (slow burning) Mixture contributed to the cracked Manifold, and symptoms of a "Lean Stumble", in the first place...in other words: Lean Stumble came first!].

After the cracked Manifold was removed from engine and separated completely, it

can be seen that casting quality was good and probably didn't contribute to the

cracks...maybe the extra heat of a Lean Mixture...otherwise, its difficult to

know...

----------------------------------

From the How-to-Impress-the-Wife (or maybe not) - Dept!

Baking on a coating in the oven.

----------------------------------

From the I-Wish-I-Had-it-Dept...for the man who loves SUs...like ME!

We don't need no stinking Webers!

----------------------------------

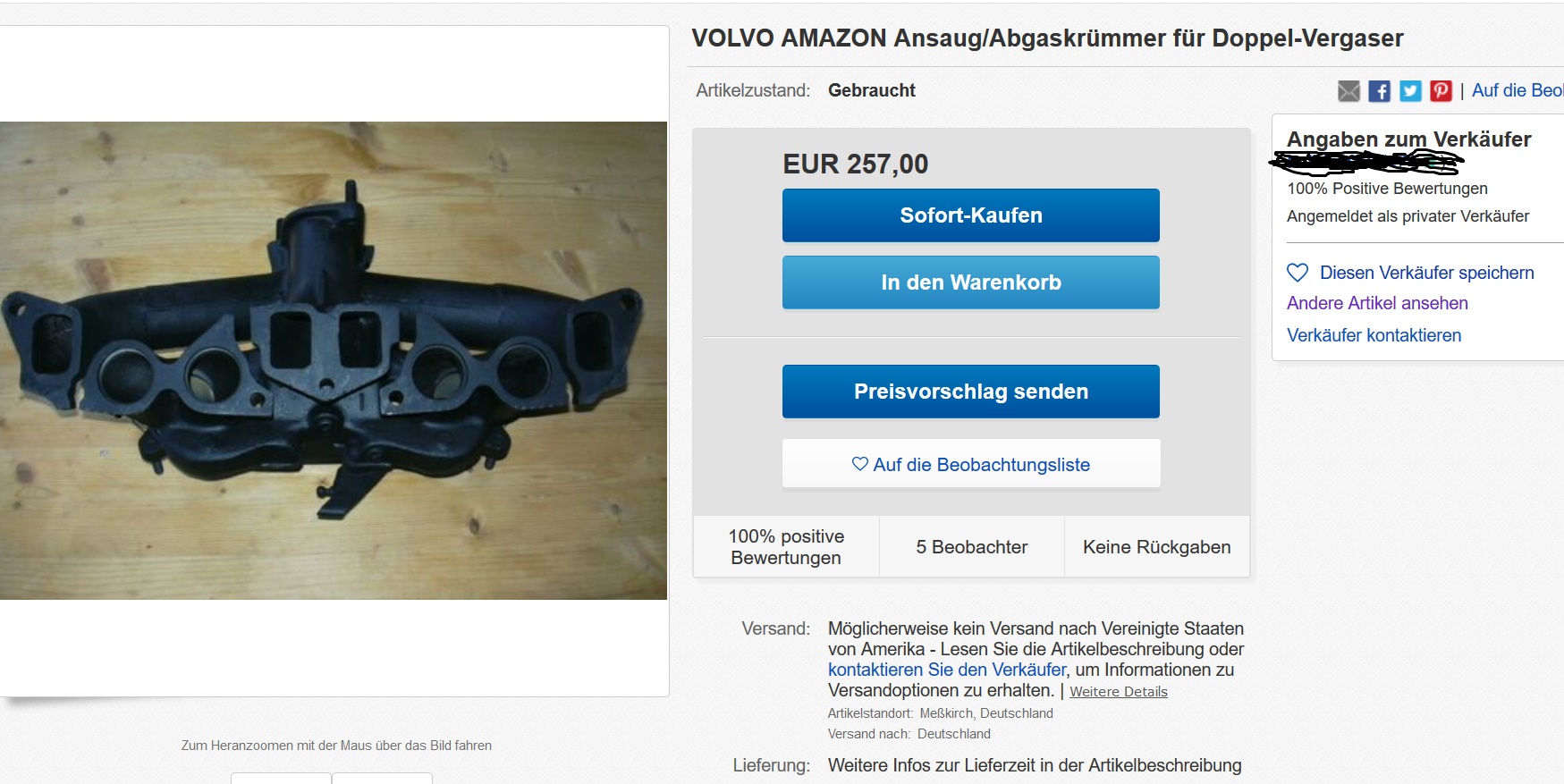

Suggested Uses for Dual-Throttle Manifold

New Olympic Sport:

Best suggested use!

The are available...cheap!

A Euro-Epay Bargain (the shipping could get you though)!

Bernhard B. of the Volvoniacs submitted this Greta T. approved use for the Dual-throttle manifold...

For vintage Volvo owners who don't own small watercraft, who are not into Olympic events or Swedish botany ...this owner took a Dual Throttle Manifold, and strategically cut away all of the Intake aberration, leaving himself with a beefy cast, good flowing 4-2 Exhaust Man, which when paired with a pre '66 alu 2-4 Intake, will give a very decent (exhaust) flowing and (intake) breathing setup! Note that stepped washers, are necessary with this arrangement of Manifolds, as seen above, but that is a small price to pay!

Sigfred Søvik pictures posted with his kind permission.

First cuts.

A lot of noisy, dirty grinding later results in a very nice flowing, cast, 4-2

Exhaust Man!

Modified Exhaust Man, paired with a dual carb alu 2-4 Intake...a very nice setup!

----------------------------------

Some pictures were "harvested" from the Internut and credited to the source where possible. Otherwise, these notes are Copyright © 2017-2022. Ronald Kwas. The terms Volvo, SU, ZS, Solex, and Weber are used for reference only. I have no affiliation with any of these companies other than to try to keep their products working for me, help other enthusiasts do the same, and also present my highly opinionated results of the use of their products here. The information presented comes from my own experience and carefully considered opinion, and can be used (or not!), or ridiculed and laughed at, or worshipped, at the readers discretion. As with any recipe, your results may vary, and you are, and will always be, in charge of your own knuckles and future!

You are welcome to use the information here in good health, and for your own non-commercial purposes, but if you reprint or otherwise republish this article, you must give credit to the author or link back to the SwEm site as the source. If you don’t, you’re just a lazy, scum sucking plagiarist, and the Boston Globe wants you! As always, if you can supply corrections, or additional objective information or experience, I will always consider it, and consider working it into the next revision of this article...along with likely the odd metaphor and probably wise-a** comment.