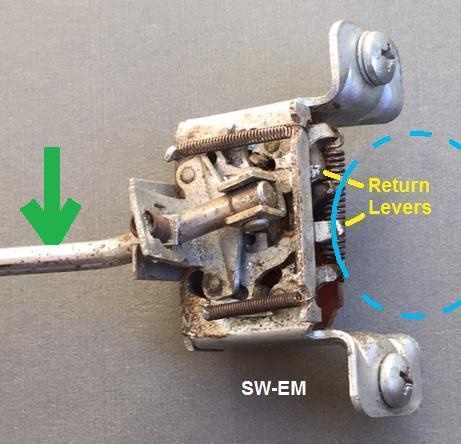

Directional Indicator Switch, as removed from a vehicle, shown in neutral position.

Cleaning and refurbishing/lubing will come later.

Directional Indicator Switch Mechanism

------------------------------

first published Oct 2016 R. Kwas, revisions on-going (mostly when the spirit moves me!)

------------------------------

Removing Steering Wheel

Bullet Connectors

------------------------------

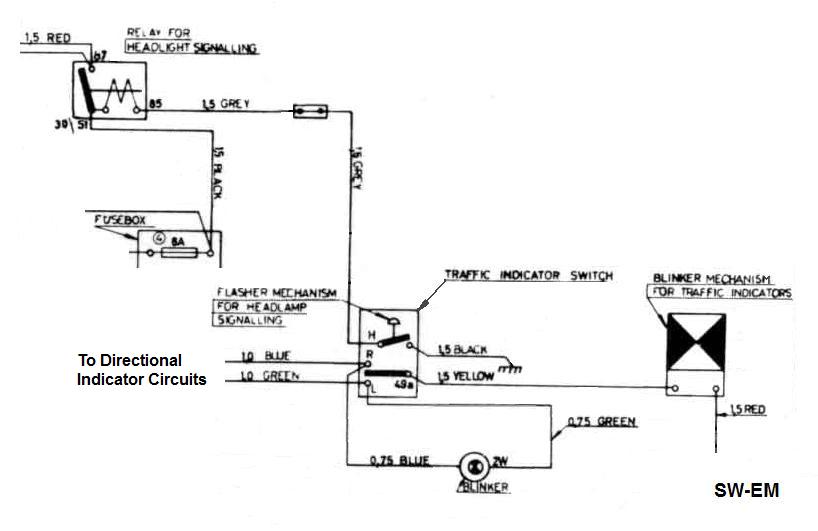

The Directional Indicator Switch (also "Traffic Indicator Switch" on Wiring Diagrams) is a mechanical assembly supplied by SWF. The switch is well-made has two separate electrical sections; one for Headlight Hibeam flashing and the other for Directional Indicating (see Directional Indicator in-circuit). These notes will focus on the Directional Indicator part and its mechanical self-canceling feature. The mechanism which cancels the driver operated latching lever, is activated by edges of a "Canceling Collar" on the Steering Column acting upon Return Levers on the Switch. The canceling mechanism is robust but must be well lubricated to prevent accelerated wear and unnecessarily early failure.

Directional Indicator Switch, as removed from a vehicle, shown in neutral position.

Cleaning and refurbishing/lubing will come later.

Dir Ind Sw shown in latched down (Left Signaling,

Green) position,

which extends the lower of the two Return Levers into the arc path of the Canceling

Collar shown in Blue.

When Canceling Collar sweeps around as St Wheel is turned, it catches the Lever

edge which resets the Switch.

Exploded Factory Assembly Diagram showing

Companion Flange (I prefer to call it a Canceling Collar).

As the Steering Column turns in either direction, the edges of Collar act upon

the Return Levers, if either is extended, resetting the mechanism.

Canceling Collar by itself. Area contacted by Return Levers of switch is highlighted in

Yellow.

Contributor Jeff Clark, notes that the Canceling Collar on his '71 1800E "is a tough plastic part". Evident are also significant wear-grooves where the Return Levers of Switch contact the plastic...I recommended he reassemble with a dab of plastic compatible, non-drooping lube like Super-Lube, in the contact area, to slow down further wear...lubing the earlier metal Canceling Collar is less important from a wear-groove standpoint, but still good practice from a noise standpoint.

Jeff Clark picture used with his kind permission.

Dir Ind Sw, connector side. SWF logo is evident, as well as terminal

identifiers in the phenolic base (also added in the graphic for clarification).

It is one of the only places in the 122 electrical system that

Bullet Connectors are used, but these are

of a high reliability double split-barrel style. Reconnect using

ACZP, of course! Two Return Levers

at Yellow, are visible in their

normal, retracted positions. These are loaded into the

Canceling Collar by the significant Spring visible.

------------------------------

Responses to thread ( http://www.volvoforums.org.uk/showthread.php?p=2176260#post2176260 ) Indicator Jumping Out [Clarifications and comments not part of the original posting added]:

In general, the Directional Indicator Switch is a little mechanical marvel...and

a bit more complicated than a typical switch, as it includes that cute spring

activated cancellation mechanism (as

well as the Pull-Back Switch for Headlight Flashing, which is available and

functional in any of the three positions)...as such, it must also be lubricated to

minimize wear and allow the mechanism to function well long-term. A dielectric

Grease (or any other grease for that

matter!) works well here.

The Return Mechanism of Switch explained: As the Dir Ind Sw is activated either

up or down (R or L indication), tiny (Return) Levers (one for right, a different

one for left) extend from the Switch, in the direction of a

Cancellation Collar/Sleeve on the

Steering Column (Volvo calls it a

Companion Flange in the exploded Assembly Diagram). The Return Levers are a

part of a sensitive trigger mechanism, which when

touched, causes the Ind Lever to spring back to the neutral position. The Collar

on the St Column is not complete, but interrupted, so that as the edge of the

collar interruption touches the extended Return Lever as St Wheel is turned

(in either direction), it

triggers "Cancellation" of the Indicator.

I've see several causes for "Non-Cancellation"

(or not latching in place when

activating), but it can be caused any factor

which interferes with this somewhat precision action...but first, as a precision

mechanism, it should be clean (of fuzzies which can occur in the passenger

compartment...especially if Fido rides along often!) and lubricated! I've also

seen a worn collar causing poor/intermittent contact with Return Lever

[most recently, heard of a bent Return

Lever. See:

https://forums.swedespeed.com/showthread.php?581639-Turn-signal-indicator

] ...I've

also seen that collar be turned on the St Column causing return only when

turning St Wheel in one direction... Sometimes the precision mechanism just gets

worn (latching detent gets worn away) from non-lubrication, and switch must be replaced...but

I have seen them simply become sluggish from lack of lubrication or being gummed

up with Fido hairs...this is when a good flushing with

Brake or

Carb Cleaner blasted in with

the Snoozle (What

is a Snoozle? ), followed after solvent dries, by lubrication, can bring them back

to function...it all depends on what one finds upon close inspection...

Close inspection and Troubleshooting requires

removal of St Wheel(41), and Plastic

Cowl(40). Then Dir Ind Sw may be removed and Trigger Levers and their action may be

checked, and if found to be working OK, carefully lubed. Edges of Collar on St

Column which touch Return Levers can also be checked (and lubed!) at that time.

Removing Steering Wheel: Often, they do not require a puller...simply bend away Nut securing tab of Securing Washer(57 or 58), partially loosen Nut(56), and have a smart pull on the wheel...often it will release from the flanges against the Nut with a POP, as the Nut stops it!...a bit of rocking left to right may help...if not, a few taps on the Shaft by a helper, while applying pulling force on the St Wheel, will often cause it to release...mark position before complete removal to ease replacement at the right angle! [Only partially loosening Nut keeps one from pulling the Wheel off uncontrollably into one's own face, causing best-case only a black eye, and questions for details about the fight one got into from friends and associates, worst-case possibly necessitating emergency trips to the dentist, and resulting in smart-a** and other less-than-helpful comments from the wife...]

------------------------------

Links:

Electrical Troubleshooting Notes: Directional Signals

http://www.sw-em.com/Blinker_Relay_or_Element.htm

------------------------------

Reference Information:

Directional Indicator in-circuit:

Dir Ind Sw circuits, showing two separate circuits.

Bullet Connectors, more often found in British Harnesses such as the early P1800s, but are also used on the Dir Ind Sw as they are a bit smaller and so can be stacked closer together occupying an absolute minimum of real estate. That's an advantage, because it allows the Switch to be shrunk to a minimum size. Bullet connectors also have a large surface area of the two parts which make contact for a very low Resistance connection...also an advantage, but I like them less than the "The Lowly .250" Push-On Terminal" because the contact areas of Bullet Conns are spring loaded flat on a flat, effectively wrapped-around surface, and do not benefit from and edge cutting into through surface oxidation and into the other as with "The Lowly .250" Push-On Terminal" .

In the authors opinion, the Push-On terminal is better than the Bullet Connector, because of that cutting action which is not present in the Bullet Connector! In searching around for info on the Bullet Connectors, I did find this site specializing in vintage British Motorcycles with excellent in-depth info on 4.7mm (OD) Bullet Connectors, and more. At that Britbike.com site, Author: Magnetoman has put together excellent detailed info thread: http://www.britbike.com/forums/ubbthreads.php?ubb=showflat&Number=644857 Scroll down to post No. 45178! He also advocates the use of Deoxit D5, but he still recommends Dielectric Grease...I have contacted him and will enlighten and convert him to use ACZP...especially on motorcycles, where connections can be saturated/submerged (not to mention the rider!).

Excerpt from my e-mail to Magnetoman:

"My position is...if I want the best crimped connection I can get...I solder it! ...because nothing beats a Gas-Tight-Connection (term from connector engineering your are probably familiar with)! ...a philosophy that is clearly even more important on a motorcycle, where everything (including the rider!), not just under the hood as in a car, can be completely saturated...so I was also particularly interested to see your take on soldering and connector treatments such as Deoxit and Dielectric Grease. I am happy to see you have discovered Deoxit (long known to me also), but along with most other mechanics, you only talk about dielectric grease, which gives encapsulation (admittedly an advantage), but which can also lock in corrosion (not so good!)... This is where I do want to make you aware of a product class beyond dielectric grease...it is a product from the domestic/industrial electric distribution field...namely ACZP (my generic term for grease filled with Zinc dust). I was turned on to a sample of Penetrox A (Burndy's version) of this material by a former Burndy employee some 20+ years ago, and have never looked back. In addition to encapsulation, the zinc content also neutralizes and corrosion which might start under that encapsulation and at a microscopic and chemical level. I have been using it for those 20+ years and have been on a one-man campaign to convert vintage car owners (not just Volvo...but ALL!) as far as I'm concerned, connections treated with it would not care if they were submerged...and that can certainly be the case on a bike!"

------------------------------

Links:

------------------------------

External material attributed. Otherwise, this article is Copyright © 2016-2024 Ronald Kwas. The terms Volvo and SWF are used for reference only. I have no affiliation with either company other than to try to keep the vintage products of both working for me, and to help and encourage other enthusiasts do the same. The information presented here comes from factory manuals or my own experience, and carefully considered opinion, and can be used or not, or ridiculed and laughed at, at the readers discretion. As with any recipe, your results may vary, and you are, and will always be, in charge of your own knuckles and future!

You are welcome to use the information here in good health, and for your own non-commercial purposes, but if you reprint or otherwise republish this article, you must give credit to the author or link back to the SwEm site as the source. If you donít, youíre just a lazy, scum sucking plagiarist, and the Boston Globe wants you! As always, if you can supply corrections, or additional objective information or experience, I will always consider it, and consider working it into future revisions of these article...along with likely the odd metaphor and maybe wise-a** comment, as they come to me...