The two "Special Bolts" which need to be removed to disassemble the Steering Column Ignition Lock from Steering Column...but how??

Late-Production Ignition Lock Removal

First Published Jan 2022, R. Kwas [Comments added]

-------------------------------

Reference Information:

-------------------------------

The following information applies to the very last Amazons produced, where Ignition Switch was located on the Steering Column, as well as also the late production (injected) 1800s, and the follow-on 140 series vehicles. All of these vehicles have the Steering Column Ignition Lock as the next implementation of an effective anti-theft measure, after the successful but complicated "Armored Ignition System" of the earlier vehicles. The Steering Column Ignition Lock assembly was manufactured by Nieman in Germany, and is therefore metric. This article details "Special Actions" necessary and required to remove the Ignition Switch Assembly, because as part of a vehicle anti-theft system, the assembly was secured to the Steering Column with a special kind of bolt which left the assembly unable to disassemble or defeat without these "Special Actions".

This late Amazon owner has recently needed to remove the assembly from the Steering Column, so I thought I would add his experience and pictures, and some comments to help others needing to do the same.

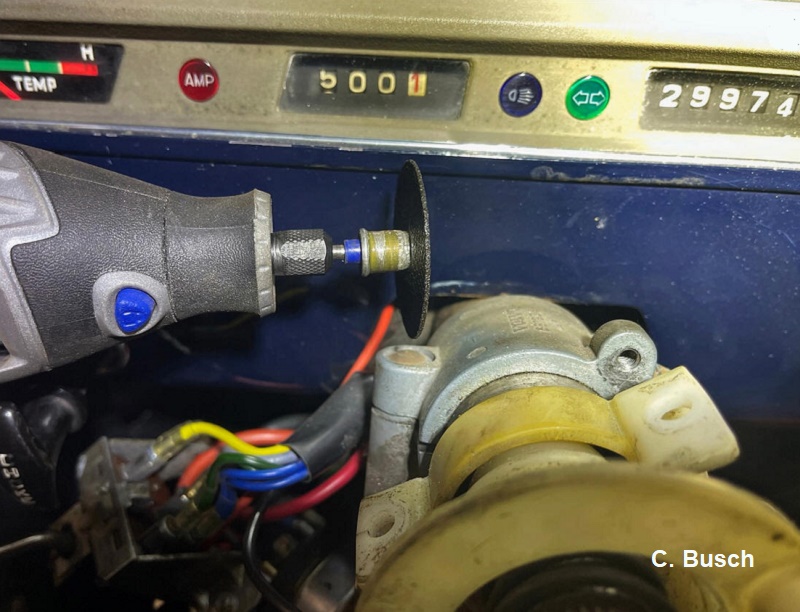

Constant Busch pictures, reposted with his kind permission.

The two "Special Bolts" which need to be removed to disassemble the Steering Column

Ignition Lock from Steering Column...but how??

A slot is all that is needed in the bolts, and a Dremel with a cut-off disc is just the tool to do it!

"Special Actions" in progress!

The common recommended preparation for removing the bolts in question is to Dremel slots which can then be turned with a straight-blade screwdriver.

After disassembly, made possible by adding slots to the bolts. Evidence of

the original broken-off Bolt-head fracture is clearly evident at

Orange, as well as the slots

added on both fasteners.

The deed is done, and the Assembly is removed from Steering Column and laid out

for inspection.

Reassembly: If the security factor is to be retained on reassembly, similar special Bolts need to be procured and used at that time. If however the security factor is less important (having been taken over by some other form of alarm or engine disabling provision), normal hexhead hardware can be used, but since the edges of the original rounded bolthead sit in a counterbored pocket...these hexbolts will require at little time on a lathe, in order to machine away part of the hex, to allow them to also fit into this pocket, yet with enough hex protruding to allow future disassembly with normal tools...BUT, an even simpler solution would be to use a Socket Head Cap Screw of the correct M8 thread and length!...their heads are already a smaller OD, and there would no issue applying a tool for fastening, or removing in the future...!

-------------------------------

Discussion:

My response to a suggestion that Volvo did not consider what would be required if this assembly ever needed to be removed for service: "...I'm quite certain that Volvo totally considered what might be required for future service/replacement of this assembly, and still made a conscious decision in light of anti-theft requirements, to indeed use the frangible security bolts, that it would require "Special Action" you actually needed to undertake to remove. A thief is not going to have the tools, or time, or inclination for these "Special Actions", and would move on to easier targets...Result: Anti-theft requirement satisfied!"

-------------------------------

Links:

Frangible Hardware (Nuts) are, for instance, also used by NASA to intentionally and instantly and under precise control, remove the fastening forces...like for instance separating rocket stages, or the Solid Rocket Boosters of the Space Shuttle: https://en.wikipedia.org/wiki/Frangible_nut

-------------------------------

Reference Information:

Frangible hardware is designed into assemblies when an "intentional location of breakage" is necessary. Sometimes this breakage is necessary to protect more important/expensive components from damage in the event of "special circumstances"...like saving the gearbox of your snow-blower (this is a common and well-known example)...here the "Shear-Pins" or "Shear-Bolts" are designed as an intentional weak-link which will break, stopping the drive to the auger, like for instance when you have ingested that 4 x 4 wheel-chock in the driveway which you forgot to remove in a pre-snow prep (I'm not admitting to anything of the sort here...honest!). Other times, like in this situation, the frangible hardware was designed-in to intentionally break during assembly, leaving no bolthead onto which a potential carthief could apply a wrench. For those who legitimately needed to remove the hardware at a later time, they could use more time, tools, and employ "Special Methods and Actions".

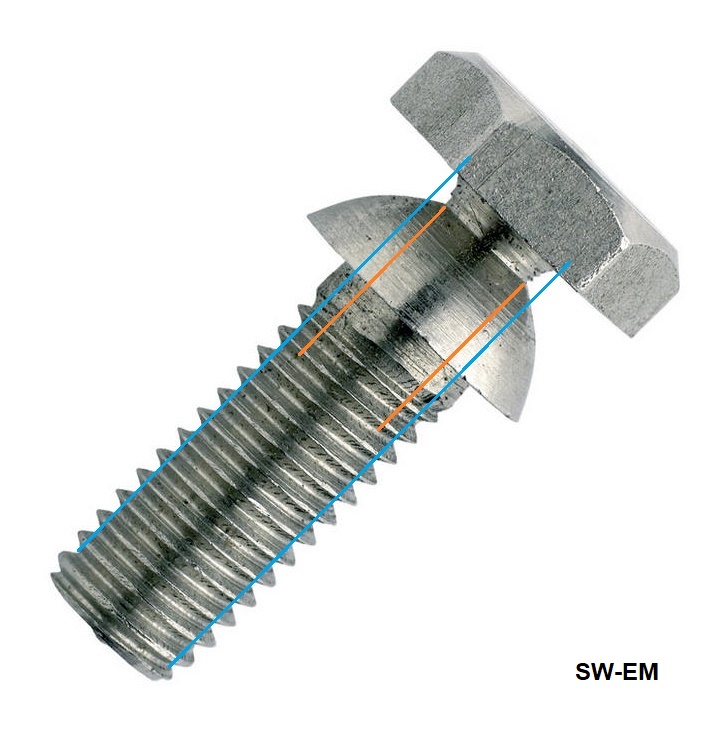

This is what the security bolts looked like before installation of the Assembly:

Security frangible bolt intended to be driven in to fasten the Steering Column

mounted Ignition Switch ...notice the OD at the intended point of breakage

(ORANGE), is significantly less

than the root of the fastener (Blue),

so during installation, torque from the applying tool easily breaks away the

driving hexhead, while leaving the clamping Bolthead to do its job.

-------------------------------

External material sources are attributed. Otherwise, this article is Copyright © 2022. Ronald Kwas. The terms Volvo and Nieman are used for reference only. I have no affiliation with either company other than to keep its products working for me, help other enthusiasts do the same, and also present my highly opinionated results of the use of their products here. The information presented comes from my own experience and carefully considered opinion, and can be used (or not!), or ridiculed and laughed at, or worshipped, at the readers discretion. As with any recipe, your results may vary, and you are, and will always be, in charge of your own knuckles, and future!

You are welcome to use the information here in good health, and for your own non-commercial purposes, but if you reprint or otherwise republish this article, you must give credit to the author or link back to the SwEm site as the source. If you donít, youíre just a lazy, scum sucking plagiarist, and the Boston Globe wants you! As always, if you can supply corrections, or additional objective information or experience, I will always consider it, and consider working it into the next revision of this article...along with likely the unique metaphor and probably (likely) wise-a** comment.