SU Carb Service

R. Kwas Jan 2008 - 2018 (updated continuously)

[Comments added]

Link to full Tech Article on

SU Carbs

SU Carb Service - Lite

SU Contact and No-Contact Areas

Service - Expanded Version

Check Metering Needle

installation into Dashpot

Inspection of

Fuelbowl

Lids, Floats, and Bowlvalves

External Combustion B18

Check and Adjustment of

Fuelbowl Floats

-------------------------------

SU Carb Service - Lite

For those who wouldn’t know a constant velocity, variable Venturi, side-draft SU carb from an

orgasmatron, the prospect

of cleaning and performing a preventative maintenance, or even just touching

them can be pretty intimidating…one wouldn’t want to break or mess up

anything...all those complicated mechanical linkages...and add to that, the fact

that there are two under the hood…where does one start? To help with

this, here is a good, first-time, low risk introduction to getting to know your

SUs carbs. While the highlighted Inspection Items included are what I

consider to be important items for their correct function, and what to check and

watch for, this is only intended as a familiarization, so adjustments are not

included. Lubrication is included for reassembly, because it is important, and

Adjustments will be covered in the

Service - Expanded Version second

half.

Beyond the Lite and Expanded sections presented here, many

further, more highly detailed Notes and Tech Articles can be found at the

Link to full Tech Article on

SU Carbs but this is the place to start for the

SU beginner!

Before reader gets started with their own hands-on session,

viewing the superb two part video by John Twist of University Motors is

recommended to understand these little mechanical marvels. While Twist is

an MG specialist (we won't hold that against him) the presentation covers both

theoretical, and how a particular requirement is practically implemented in the

SU design, and

applies perfectly to the Volvo configuration of the carbs:

Part 1:

https://www.youtube.com/watch?v=7GRAcqDySog

Part 2.

https://www.youtube.com/watch?v=60Bj_2cZQnc

Recommended to have on-hand

for this procedure: General tools, soft clean rags, spray type carburetor

cleaner (with pinpoint applicator snoozle), Automatic Transmission

Fluid (ATF),

graphite grease (or graphite filled anti-seize),

preferably in a syringe applicator, a three foot length of 1/4” ID fuelline,

plenty of light under the hood.

Disclaimer:

This procedure has been prepared with the greatest care, and I stand by it,

having performed it many times myself, but it is only a guide to be used in

addition to normal, cautious shop practice. I cannot be responsible for your

specific actions (especially the dumb ones which cause damage or injury!). You alone are in charge of you knuckles and future! Work Safely!

The following steps are

performed with IGN off; battery may be left in place and connected.

Exploded Diagram of a (late) SU HS6 Carb as used on Vintage Volvos. Referenced

Components are Highlighted.

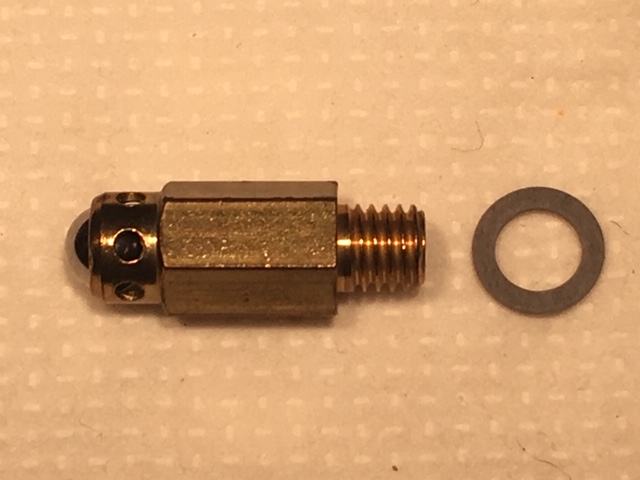

Dome assembly(11), Dashpot (12), Dampening Valve (15), Fiber

Washer (16), Guidetube and Spring (14), Idle Screw (10), Fast Idle

Cam (55) and Fast Idle Screw (49), Throttle Linkage/Plate (43, 44, 46), Jet

assembly (22 - 30), Lifting Pin and Spring (5, 6), , , Fuelbowl lid (36), lidscrew (38), Bowlvalve

Assembly (40), Bowl Float (41), Float Pin (42).

Disassembly and Static

Inspection: Remove Air Filters. If

vehicle is equipped with the earlier (two Air Filter bolt) type, this will require a wrench on the boltheads, and probably a second

wrench on the nuts behind the flange on the carb body. The loose

nuts are not captured, and can to fall and get lost, so care needs to be taken not to allow this to

happen. On later (three Air Filter bolt) types, the flanges were threaded which eliminated

the nuts. This allows a simpler removal with just one wrench and there are no nuts to

fall and get lost.

Having removed the Air Filters,

part of the Dashpots of both carbs are visible just inside the throat of carbs,

in the all-the-way-down-against-the-bridge (venturi) position. Inspection

Item 1: Check Dashpot travel. By raising lightly with a finger, check each

Dashpot for free, smooth, damped lifting, and more rapid, undamped, falling, all

the way back down to the venturi with an audible clunk. As each Dashpot is

raised, the tapered, brass, fuel metering needle will become visible, a bit

further into the throat, mounted at the bottom center of the circular Dashpot.

Aside from the linkages, and the Fuelbowl valve, the movement of the Dashpot is

really what makes the simple SU work so well! Because of this, it should be

clear, that Dashpot movement is one of the most, if not the most important

functions of the carbs, and so should be smooth and unobstructed, as designed

and intended.

With a screw driver, remove

the three screws holding the Dome of one carb to the carb body. Once all screws

have been removed, a gentle twist can help break the Dome free and allow it to

be carefully and slowly lifted off – along its axis! The Dashpot should remain

down, and be allowed to stay with the carb body. Once the Dome is lifted off,

its inner surface should be cleaned with spray carb cleaner and soft rags.

Cleanliness and lubrication on reassembly are important for trouble-free

operation of these mechanical carbs. Use no abrasives of any kind

on any

internal part of an SU carb*. Flush and wipe away any abrasive dust or soot on

internal components! The unidirectional dampening valve, which allows the free

fall of the Dashpot while assuring dampened rise, may be unscrewed from the Dome

top, and also flushed and wiped clean. Flush and wipe the internal bore of the

central tube. Run a soft rag through the tube. Use no metal, but for instance,

a giveaway chop-stick from the oriental restaurant of your choice for this,

which cannot scratch the precision machined bore. Place the clean Domes, and

their damper valves aside, on a clean surface.

The Dashpot, along with its

return spring, is now visible at each carb body. Both may now be carefully

lifted off - also along their axis – taking care not to drop the Dashpot back

down (without the Dome in place, there’s no centering or damping so metering

needle damage can occur if Dashpot was allowed to drop uncontrolled). Handle the

Dashpot assembly with great care, as the brass needle on the bottom surface of

Dashpot, is

critical to the function of the carb, and if bent – even slightly – will need to

be replaced, and you have just turned a fun and interesting, SU familiarization

session into a bad day, the rest of which will likely be spent on the phone,

trying to locate an immediate source for a straight replacement needle!

Pour the dampening oil out

of the top dampening tube onto a clean, white paper towel and inspect oil for

color and particulate contamination…if ATF or Marvel Mystery Oil (which can be

identified by its smell), it will be red, and an indication that one of the

recommended oils have been used, although the official damping oil is a typical

golden color. Whichever oil comes out should be thin in viscosity and quite

clean. Flush and wipe the Dashpot/metering needle assembly clean.

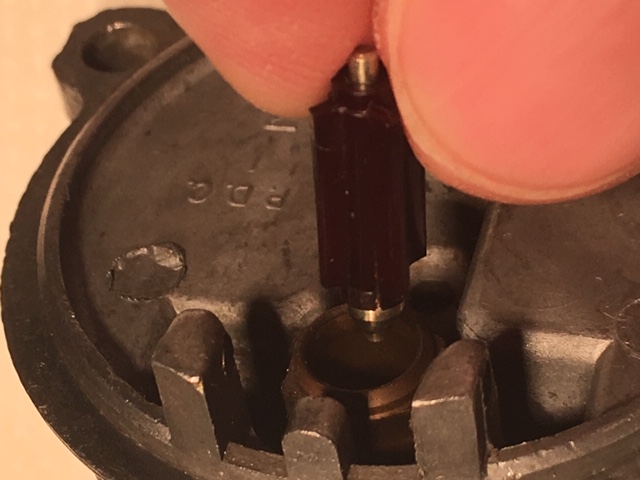

Inspection Item 2:

Check metering needle installation into Dashpot. Using a fingernail or

small straightedge, verify that the shoulder of the metering needle is flush

with the mounting surface of the Dashpot bottom. Inspection Item 3: Check

metering needle for contact damage. Visually inspect the sides of metering

needle for scratching or other signs of contact with the jet, particularly at

the fat end. None should be evident to the unaided eye. Carefully place the

cleaned Dashpot assembly and spring aside, with their respective Dome, taking

care not to allow the round parts to roll away.

With the filters, Domes and

Dashpots of both carbs removed, cleaned and safely grouped by carb (parts would

probably fit and allow swapping, but why take chances, and introduce a

variable?), throttles plates are now visible even further down the carb throat.

Inspection Item 4: Check for carb linkage for synchronization. Slowly

actuate the throttle linkage at or near the mount on firewall to simulate normal

driver input, while observing the actual movement of both throttle

plates...verify both throttles open at precisely the same point as the throttle

linkage is actuated! Using the carb cleaner, spray and gently wipe and clean

carb throat surfaces of any black soot, and Dome contact surface of

contamination. The dirtier the carbs, the more time can be spent cleaning them

at this point! Inspection Item 5: Check throttle linkage for wear at the

carbs. Wiggle the linkage where it enters the carb body, checking for side

to side motion which would occur if shaft or carb body was worn. This is a well

known wear area of high mileage carbs, responsible for “false air”. If it

weren’t for this wear, SU carbs would probably last forever!

Inspection Item 6:

Check Choke function. Verify both

carb jets are drawn down from the venturi by about 1/4 inch as a helper slowly

activates the choke control on Dashboard, by pulling it out from its rest position to fully

pulled position. At the same time, verify the fast idle cams are rotating and

contacting the fast idle adjustment screws and thereby opening the throttle

plates slightly.

You have now opened the SU

carb and have seen into its soul, and observed it’s most intimate secrets. Take

notice of the fact that up to this point, you have only inspected and cleaned

parts, so have changed (and given a careful reassembly, will change),

nothing in the settings of the carbs! Take notice also, that up to this point,

very little magic, if any, has occurred!

[Note that missing from the

above is the removal, disassembly and Inspection of Fuelbowl Lids and

Bowlvalves.

Simple as these also are, their reassembly can often be accompanied by

overflowing Fuelbowls upon restart, which would serve to totally spook some poor

beginner into never going anywhere near the his carbs again!...I therefore

considered it beyond the scope of this Service - Lite section and

have included it in the Service - Expanded Version section!]

Lubing and Reassembly:

As the mechanical devices they are, SU carbs need to be lubricated to function

well!

Lube linkages:

Graphite grease or graphite containing anti-seize is an excellent lube for low

movement/high bearing pressure applications because the graphite particles stand

up well in the long haul and are not displaced from where they are needed. (LINK:

Anti-Seize) Unfortunately, using it sloppily will also make a mess.

A syringe pinpoint applicator works well and keeps the mess factor to a minimum

(personally, I’d rather have my carbs be well lubricated and have a little mess

than clean and bone dry). Lube the ball linkages leading up to the carbs

(retaining pin for the joints can be removed and ball levered out of spring

loaded socket, cleaned, and greased...once lubed it will only need to be redone

in ten years or 100,000miles, whichever comes first!), the throttle shaft

entrance through the carb body (as best as possible since its buried behind

hardware), and also the jet tubes, to assure smooth operation for a long time

with minimum wear of components. Wipe off excess.

Lube Dashpot Lifting

Pin: Apply a drop of ATF to the

lifting pin mechanism and work the pin a number of times until free. This is

strictly a built in service-aid which is never moving during normal service. It

is moved only during maintenance operations, to lift the Dashpot a constant

amount, so these tend to get locked into place by debris and/or corrosion.

Lube Dashpot:

Since the Dashpot spends its service life sliding up and down guided by its

shaft sliding in the central guidetube of the Dome, these must be well lubed.

Apply a film of ATF to the Dashpot shaft. Replace the Dashpot in carb body,

gently allowing the metering needle to slide into the jet as the slot is aligned

with the alignment tab in carb body. Fill shaft with ATF to slightly (1/4” )

below the top. Replace the spring onto the Dashpot shaft. Replace the

Dome

(without damping valve installed) by gently aligning it onto the Dashpot shaft,

and sliding it down onto the Dashpot tube until it bottoms onto its mounting

surface. Only one circular alignment of the Dome will align all three securing

screws. Turn the Dome to find this location...this turning action is actually

good in assuring the clean and perfectly flat interface of the two components,

and therefore helps the perfect alignment of the Dome, and guided Dashpot within

the carb body (and metering needle within the jet).

Replace securing screws and

their lock-washers (a dab of anti-seize on the screw threads is a good idea here

to prevent galvanic corrosion, as these will be going into the dissimilar

aluminum carb. body.)

Once the Dashpot and Dome

assembly are secured in place on the carb body, repeat the previous test for

smooth Dashpot travel, verifying that Dashpot bottoms out completely on the

bridge with a clunk. The Dashpot will follow a finger directly, without the

damping valve installed. If good alignment and smooth motion is verified,

install damping valve by inserting (brass) valve into Dome and Dashpot tube,

pushing it down and into the ATF, finally snugging it handtight only

(Beware: Overtightening or tightening with a wrench will surely break the

threaded Bakelite part...DON'T DO IT!). The fiber washer limits the tightening force and gives

some locking action against the vibration present in operation.

Reassembly:

This is pretty much the reverse of disassembly as they say, and it shouldn’t be

rushed...especially if it is the first time...rushing causes parts to be left

over and indigestion!

Operational Check:

Once the reassembly is complete, the engine may be normally started. Idle

should not be much different that before Disassembly and Inspection,

because no adjustments were made, but if a test drive reveals any truly

noticeable change after only the inspection and lube parts of this procedure

have been performed, then it probably really needed them and could also benefit

from the adjustments in the following section...

--------------------

* My response to suggestion to using "Brasso" polish

in a VOC thread: Carburetor Issue:

https://www.volvoforums.org.uk/showthread.php?t=281041

"Brasso is a polish and therefore abrasive (if only

mildly)...this means it removes material (if only minutely) which results in

changing the precision clearance between Dashpot and Dome tubes, and this is to

be avoided...I recommend against abrasive of any kind...I do recommend

cleaning and flushing (especially the Dashpot and Dome tubes) with a

hydro-carbon solvent (spirits, carb-cleaner, etc.), wiping absolutely clean, and

lubing pre-installation with ATF."

SU Contact

and No-Contact Areas:

SU cutaway showing precision, lubricated contact area between (Dashpot

and Dome tubes, by way of an oil film!) at Green,

and precision clearance non-contact area between Dashpot outer

circumference and Dome Inner circumference) at

Red.

Orange is where Metering Needle

protrudes into Jet orifice. This is also a non-contact area. The two

should not be making contact...contact is caused by non-concentricity

between the two, either as a result of a non-centered Jet, bent Metering Needle

or some other out-of-the-ordinary-condition. This contact causes sticking

as they should freely move, and results in wear on the Metering Needle, so it

must be remedied, but this is advanced service beyond the scope of Carb

familiarization covered here.

http://www.sw-em.com/su_carbs.htm#Tuning%20and%20adjusting%20SUs ...and

here:

http://www.sw-em.com/service%20notes.htm#Centering%20SU%20jets Note:

If upon inspection, signs of contact (in the form of longitudinal scratches) or (or worse) wear are evident on the

Metering Needle, carbs can be reassembled (on the basis that if engine was

working, it should work as well again)...but this is not right, and

should be addressed as soon as possible...again, it is beyond the scope of

simple familiarization, but is an important factor in the proper operation of

these carbs, so must be corrected.

End of SU Carb Service –

Lite

-------------------------

SU Carb Service - Expanded Version (including

Adjustments)

Adjustments:

If in the course of performing the previous cleaning and preventative

maintenance, items were noticed, as explained in the Inspection Items,

which didn’t seem to be as they should, the carbs may require some adjustments.

When finished making adjustments, a roadtest is always the best check...

Inspection Item 1:

Check Dashpot travel. If for

instance, there is contamination between the Dashpot and guidetube, or dirt on

the carb surface which the Dome bolts to, or a bent metering needle, or an uncentered jet, movement can be negatively affected or in the worst case,

totally jammed. This needs to be corrected, or the carb can’t function as

designed.

Adjustment:

There is not much to adjust here...clean

and lubed, and aligned and unbent components should allow smooth Dashpot travel

along its entire range. As

final check after any work is performed on a carb, and the the Dashpot,

Return Spring in place, and Dome secured normally to the Carb Housing, the Dashpot must be

able to travel through its entire range of motion smoothly.

Link to Service Notes: Centering

Jet

Inspection Item 2:

Check Metering Needle installation into Dashpot.

If metering needle shoulder is not flush with bottom surface of Dashpot it

should be adjusted to that location by loosening setscrew in side of Dashpot

which secures it, adjusted, and Setscrew retighted. If a brass Metering Needles

is bent and the carb is reassembled, it will likely make contact with the jet as

Dashpot falls, jamming Dashpot in a raised position and before bottom of Dashpot

meets the Venturi, so extreme care is called

for when trying to loosen a stubborn needle...usually the needle can be loosened

by hand, but if not and one has to use tools which are easily capable of

applying enough force to turn the needle into a pretzel, extreme care must be

exercised...I’ve have had good results (no disasters in the form of bent

needles!) by loosening holding Setscrew, wrapping a piece of protective, yet

grippy leather around

the fat base of needle and very carefully applying just enough twisting force to

persuade the needle to loosen its grip on the socket. A light film of graphite

grease on the setscrew threads and needle base would certainly prevent such

difficulties.

Checking Metering Needle position with a straightedge.

MN securing Setscrew is evident in the recess.

Adjustment:

If MN is found to need relocation, and

moved, mixture and idle

adjustments will be need to be checked after reassembly and startup. See also

LINK Mixture Checking.

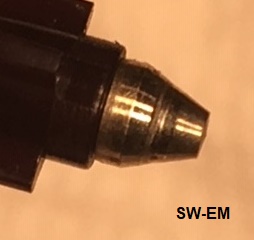

Inspection Item 3:

Check metering needle for contact damage.

Inspection should be performed under a good light-source! If contact has occurred for any reason between the brass

Metering Needle and

jet, the soft brass will show scratches or worse. This will probably result in

taking material away, resulting in enrichening at idle and possibly higher RPMs.

No

contact and no scratching or changing the needle dimensions in any way is

preferred, some light sign of contact may be evident (without scratching or

insult to the surface), but if excessive or clear indications of scratching or

changes to the MN surface or dimensions are evident, replacing the needle with an identical one (labeled

on side of base with a two letter code, i.e. KD, ZH) is about the only option.

See also:

Metering Needles

used on various engine configurations

Metering Needle profile is identified with punched-in characters.

Adjustment:

If needle is moved or replaced, avoid

scarring identifying characters when securing with set-screw, and again, mixture and

idle adjustments will be required after reassembly and startup.

Inspection Item 4:

Check for carb linkage for synchronization.

If carbs are found to be “out of synch”, that is, one throttle plate opens

before the other as throttle linkage is slowly actuated, this will case uneven

running at idle and above. This should be adjusted out by loosening the

clampnuts which lock throttle shaft to carb throttle linkage, and rotating shaft

accordingly. Snug the nuts and recheck.

Adjustment:

If linkage position is adjusted to

synchronize the throttle action, the idle screws, which have quite possibly have

been adjusted to compensate for this (two wrongs making a right), will need to

be adjusted to undo this “compensation”.

Inspection Item 5:

Check throttle linkage for wear at the carbs.

Unfortunately, where the throttle shafts enter the body in an SU, there was no

rotational bearing or seal against false air designed in. If these bearing

areas were also not at lubricated during their often long service life, the

resulting wear will allow unmetered false air to be sucked in past a worn

housing. This will cause general problems such as inconsistent idle, and

needing to be compensated for, by enriching the mixture.

Preferably, the throttle

shafts should be lubed where they penetrate the carb body. This will slow wear

in the long term, and prevent problems. The trouble is, that the precise place

where the lubrication needs to be is blocked and not very accessible from the

outside without disassembly, so this actually having been done in the life of

the carb is rare, with predictable results. The shafts are at least partially

accessible (from the inside!) while the Dashpots are removed. I recommend

graphite grease or graphite containing anti-seize for this (again for the

advantages of non-displacement and particulates). A syringe with a large gauge

needle (for medical purposes anyway) of about 0.50” diameter allows pinpoint

application from both sides, with the carb vacuum serving to draw the lube into

the bearing area from the outside.

Lubing throttle penetration

through carb body only, will not necessitate any adjustments.

Inspection Item 6:

Check choke function. The choke

linkage is a somewhat complicated pivot linkage activated by the pull-cable

coming from under the dashboard...rust in the cable itself, a sluggish pivot

linkage at the carb or a dry jet tube moving within its guidetube all contribute

drag which can be minimized by lubricating with graphite grease. Using a small

amount will keep the mess limited, but makes a huge improvement both in action

of the mechanisms, and wear prevention.

The inner cable should be

connected to the carb linkage such that when fully pulled at the dashboard

control, about 1/4” of lowering of the jet results as the movement is

transferred by the linkage. Loosening the Phillips screws of the wire stops

will allow this adjustment.

Lubing the choke cable is

also required periodically and once again, the advantages of particulate

graphite can make this service interval a decade! Here is a copy of the

recommended procedure from the previously posted

in Appendix 1 of the Check your Choke Tech

Article.

Adjustment:

After choke actuation has been changed, the

fast idle screws will need to be adjusted.

---------------------------------------------------------------

Inspection of

Fuelbowl

Lids, Floats and Bowlvalves

(Bowlvalve is the author's more generic term, different from Needle Valve

[because it just doesn't look anything like a needle to me!], to avoid confusion with carb Metering Needle

[which sure does look like a needle to me!] or Jet,

which refers to a completely different component of the SU Carb! Also,

for the purposes of discussion here, I will use the term Shuttle for the moving

component of the Bowlvalve.) Work

extra carefully

and with clean rags only – dirt or contamination in Fuelbowls or Bowlvalves is BAD!!

If this work is being performed after a Bowl overflow has occurred, mechanic

should be especially observant of any particulate contamination or debris, which

might have caused this...it doesn't take much in the way of foreign debris to

hold the Bowlvalve Shuttle from completely closing off fuelflow into a bowl!

Occasionally, a Float can even become compromised and filled with fuel...then it

doesn't float so well and will cause the Fuelbowl to overflow. Fuelbowl

overflowing is a particular insidious occurrence which can have an engine compartment

fire as the result if the fuel fumes find their way to an ignition source (like

the Generator/Alternator Brushes not far away!)

Not to spook anyone, but it's quite important to get this

right!

Dutch Volvo with the dreaded ECB18 (External Combustion B18)

Syndrome.

Reiterating: Cleanliness is very important in these operations!

After removing Air Filters

to allow complete access, but before removing Bowl Lids, blast Bowl Lids externally with carb cleaner, and wipe away dirt around both

the area of the lids, only then remove three lidscrews, and lift both Fuelbowl lids (leaving

connected together by the short section of fuelline), gently turning both

up-side-down while lifting them up and away from the Fuelbowls. If gasket

sealer has been used on the bowl gaskets (in a false effort to try and stop

fuel leakage due to sticking Bowlvalves and overflowing from the vent), gaskets

may separate, with part of the gasket staying with lid and part staying with

bowl. Carefully pick the one they are stuck to the most, and separate the

gasket from the other with a blade, so that gasket is saved and can be reused...if gasket is

torn apart, a new gasket will have to be fitted on reassembly. A Bowl gasket

must be in place on reassembly, or

leakage will surely result! Bowl Lid gaskets are included in rebuild kits.

Disconnect the fuel supply

hose from the front lid, catching any spilling fuel in a rag. Holding lids up

side down, compare the positions of the two floats. These determine the bowl

fuel level at which they close, and should be quite similar. Level of fuel left in

the Fuelbowl after removing lids with their floats should also be in quite

similar. If fuel levels are quite different when bowls are removed, it can be

assumed that they are also different when lids are in place. Since this is an

important prerequisite for proper operation of the SU carb, this should be checked

and possibly adjusted. See:

Check and Adjustment of

Fuelbowl Floats

Looking into the Fuelbowls

with a light, one should see clean, clear fuel with no sediment settled out on

the bottom, in the Fuelbowl Sump. A small amount of sediment is not unusual, but if there is a lot of

sediment evident in the sump of the bowl, or larger debris, this certainly makes the point for

fitting a post-fuelpump filter...after this sediment or debris reaches a certain level, it would

start being ingested into the Jet and possibly impede the fuel flow to the Jet,

possibly resulting in fuel starvation symptoms.

[Author has personally seen, and been

stumped for a little while, by this!] If a Fuelbowl overflow has

been experienced, and very little or only very fine debris is evident in the

Bowlsump, that suggest Shuttle sticking may be the cause of the overflow...this

warrants Float and Shuttle removal for inspection/service, see below.

Clean out bowlsump by

soaking fuel out with a rag, then flushing with carb cleaner, wiping and

flushing alternately. The length of fuel line can also be used to blow the bowl

sediment into a rag with a strong exhale! Finally flush the jet supply

tube by inserting snoozle into Jet at the venturi (Dashpot will have to be

removed for this), and blasting any sediment back toward the Fuelbowl and into a

rag.

Check and Adjustment of

Fuelbowl Floats The support arm of

the float is made of thin sheetmetal which can be gently bent to give the

specified gap to a dimensions of 0.125" to 0.187". A 5/32" (0.156") drill

bit laid across the Bowl Lid, as shown here, works well to put it nicely into

this range.

Float height check, using a drill bit as a gauge.

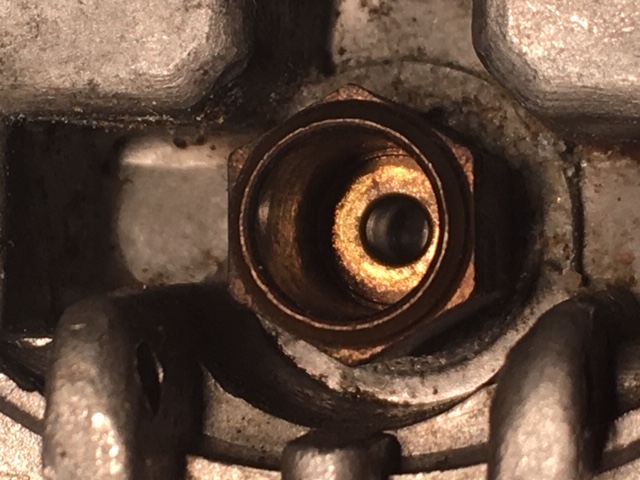

Check of Fuelbowl Valve

Shuttle and Seat Valve is actuated by action of

float. Remove the pin on which the float pivots, by gentle back and forth

rotation with needle-nose pliers while pulling. Pins typically have a flattened

area which means they can only be installed from one direction, removed by

backing it out. Once the pin is removed, the float can also be removed. As the float is

removed, valve shuttle can fall from the Valvebody, so care should be exercised not

to loose this part (hold with Valvebody horizontal!). Several different

types and styles were produced and may be found during disassembly. Using a

magnifying glass, inspect condition of conical seal area form wear or damage.

Replace if either are observed. With a light, inspect the ID of Bowlvalve

body for debris or gum or varnish fuel deposits which may cause Shuttle to stick

in place. See Disassembly of Bowl Lid below.

ID should be perfectly clean...see You Tube Link

below for a good technique to get it that way.

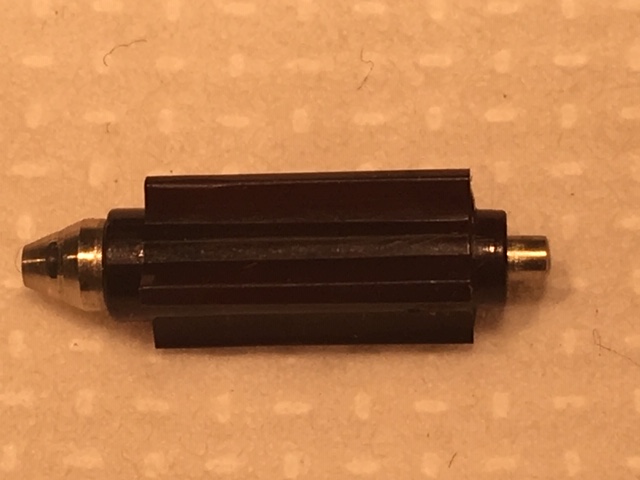

Two types of Bowlvalves Shuttles which have a conical sealing end, of brass or fuel

compatible rubber (Viton) being lifted into a seat by Float, to shut off fuelflow into Bowl. The spring-loaded plunger

(Yellow) at the bottom of right

Shuttle is intended to put some compliance into the force from the Float, and

allow some over-travel which will give the system some hysterisis.

The left Shuttle is solid and has no such compliance.

Any debris which might get between conical

surface and seat in this arrangement may get held in-place by the upward force

of the Float, causing continued overflowing of the bowl...not so good. The

Shuttle with compliance above, and Grose Jet Bowlvalve below, seem to be less

susceptible to this as the spherical principle of the seal seems to be better

capable of self cleaning. [This is

strictly the author's opinion and experience!] The shuttle stuck in

its housing can also occur to result in overflowing.

Grose Jet type Bowl Valve is a single piece assembly, employing two captured

balls and spherical sealing strategy. The (improved?) concept is that any

debris might self-clear more easily as it rolls off the sealing ball.

End of SU Carb Service -

Adjustments

--------------------

Disassembly of Bowl Lid.

Removal of brass Float Pivot Pin.

Removal of Bowlvalve Shuttle.

Bowlvalve Shuttle. Conical brass on brass seat, spring plunger type.

Inspecting Bowlvalve seat. Having a good look at the ID of the Housing

(sliding surface for Shuttle) is a good idea...it better be perfectly clean!

A 5/16" nut driver or socket can be used to remove Housing when replacing.

Inspecting Conical brass sealing area of Shuttle. This one has visible

circumference wear

groove, easily detectable with a finger nail...it is definitely due for

retirement and replacement! Bowlvalve body (Housing) and Shuttle are replaced as a

pair. The Grose-Jet Bowlvalve would seem to be at an advantage here with an

ever-changing sealing area as the balls constantly roll in service, spreading

the wear over an infinite area.

Fuelbowl Lid components.

Grose Jet (Bowlvalve!) with fiber sealing washer.

---------------------

Copied from SU Carbs Page:

Overflowing

fuel bowls The fuel

feed is a low pressure (2-3 PSI) system with a simple float and "needle valve"

(See: Bowl-Valve)

controlling the flow into the fuel bowl. Unfortunately, and more often

than just occasionally, almost every owner has seen the bowls overflow (caused

by contaminants or possibly moon phase, holding open the bowl valves)...it's

hell on fuel mileage when this is pumped out onto the street, to say nothing of

if some of the vapors are ignited by sparks at the brushes of the generator etc.

Here is an

interesting link, (https://www.youtube.com/watch?v=zlez_hdoWYk

)...originally about a (Mikuni) snow-mobile carb, but applicable to SU carb bowl

valves as an overflow preventative, because as can be seen in the video, the

bowl-valve components are absolutely similar to those of the SUs. The

trick is to polish valve body ID with brass polish on cotton swab spun with

hand-drill. I haven't tried this yet, but it seems valid to have the valve

bore be as clean as possible...even polished(!) to prevent hang-ups resulting in

overflowing...who knows what's hanging around on the valve wall...clever!...I

will do this on the next incontinent carb I run into...and show the cotton swab

here afterwards...stay tuned!

--------------------

Additional SU Carb Resources:

The previous information and procedure should help a vintage Volvo owner to get

familiar (or maybe even comfortable) with their SU carbs. If in the course of

this familiarization additional questions arise, help is (almost immediately)

available by posting to the

LINK: Brickboard

Forum.

Here is also a list of further resources

I compiled from the hands-on guys at the brickboard (thanks guys for

contributing your info and comments) (Link to

thread:

http://www.brickboard.com/RWD/index.htm?id=1254539 ) for replacement parts,

rebuilding kits, rebuilding services (I am not associated with these resources

in any way, other than being aware of them, and the contact info is presented

for convenience and in no particular

order...maybe alphabetical, maybe in the

order I got them :

Format:

Resource, Company or

Individual's Name:

Parts and Services Available:

Site or Contact info:

Comments/Experience:

-----------------------------

Burlen Fuel Systems Ltd

Spitfire House

Castle Road

Salisbury

Wiltshire

SP1 3SA

Phone:

00 44 (0)1722 412 500

Fax: 00 44 (0)1722 334 221

http://www.burlen.co.uk/

---------------------------

JOE CURTO 718)762-7878

22-09 126TH ST FAX 718)762-6287

COLLEGE POINT, NY 11356

Dave S: "He is THE

man, and you can tell him I said so."

---------------------------

Rhys Kent

Island Automotion LTD

Vancouver, Canada

http://www.sucarburetors.com

info@sucarburetors.com

----------------------------

Royze Mfg. Co.

1-800-421-2011

http://www.royze.com/Kitvolvo.htm

O.K. says: I have used their kits and have been quite happy with the price/quailty

of their products.

"Of course, if you need air filters you can always try

http://su-filters.com !"

----------------------------

Tom Bryant's Blog with his EXTENSIVE AND DETAILED

EXPLANATION of an SU rebuild:

https://thosbryant.wordpress.com/2014/01/02/su-carburetor-rebuilding-hs-6

Contact Tom Bryant at:

thosbryant@gmail.com

----------------------------

www.ztherapy.com

Matt B. says: "...does it all.

I've only ordered parts from them... never service. But I was more than

impressed with the parts and service."

-----------------------------------------

...trying to determine

linear distance along metering needle, for each flat of adjustment of the jet

adjustment nut.

LD/flat = 1 / (TPI x 6)

Formula: D = P / 6

Where: D is linear

distance

P is thread pitch

6 is the number of flats a Hex nut has

Question: What is thread

pitch of jet nut?

Answer, thanks to Brickboard

newcomer Mark (Toolguy): 0.0062" / Flat in other words,

a full turn of six Flats, is 0.037" or a bit more than one third of a

measurement increment up the needle.

A Fun-Fact for the next Volvo Trivia night!

Link to Thread:

http://www.brickboard.com/RWD/index.htm?id=1259135

-----------------------------------------------

External material

sources are attributed. Otherwise, this article is Copyright © 2016-2019. Ronald

Kwas. The terms Volvo, SU, University Motors,

Grose Jet are used for reference only. I have no affiliation with any

of these companies other than to try to keep their products working for me, help

other enthusiasts do the same, and also present my highly opinionated results of

the use of their products here, or to recommend viewing their highly informative

presentations. The information presented comes from my own

experience and carefully considered opinion, and can be used (or not!), or

ridiculed and laughed at, at the readers discretion. As with any recipe, your

results may vary, and you are, and will always be, in charge of your own

knuckles!

You are welcome to use the

information here in good health, and for your own non-commercial purposes, but

if you reprint or otherwise republish this article, you must give credit to the

author or link back to the SwEm site as the source. If you don’t, you’re just a

lazy, scum sucking plagiarist, and the Boston Globe wants you! As always, if

you can supply corrections, or additional objective information or experience, I

will always consider it, and consider working it into the next revision of this

article...along with likely the odd metaphor and probably wise-a** comment.