Electrical Troubleshooting Notes

Originally published 7/07/R. Kwas, Revisions On-Going

[Comments added!]

As a practical example of some troubleshooting which a vintage Volvo owner might need to do:

Locating Electrical Shorts

Gru Technique

Directional Signals

Fuel

Gauge

1800 Smoke in the Cockpit and Remote

Troubleshooting

Reference:

Electrical Carpentry

Electrical Terminology

------------------------------------

Locating Electrical Shorts:

(not to be confused with your "tidy-whities", which one might expect to be in the

dresser drawer...).

Mar 2018 R. Kwas

I have previously written about limiting current when performing initial checkouts after having completed major electrical work, such as replacing a harness. Link: Limiting Available Energy Limiting the amount of energy also limits the amount of damage which might occur if something was very wrong and we simply connected the vehicle Battery, capable of supplying hundreds of amps.

When using the technique (of wiring a Temporary Fuse in series with the Battery), if a short exists, or occurs when a particular control switch is activated, the TF would blow...this certainly would limit the current (to ZERO!) prevent damage, and also give a glue to the operator as to where to proceed with further inspections and tests. But as the fuse is blown, interrupting power to the suspect circuit, any subsequent tests would need to be passive, the most power coming from the Continuity Battery of the Multi-meter in use. This method is also OK, and quite safe because of the miniscule test currents involved.

Once we know we have a short (defined as an inadvertent, improper, and unwanted connection between two circuit points), we need to specifically locate it in preparation for correcting it. These notes are intended to help with that.

Beeper Technique: Using the Continuity Beeper of a Multi-meter. If we blew the fuse (be it during our Limiting Available Energy Trick during initial check-out or in some other situation) and reasonably suspect a short (to chassis) on a particular circuit, we can perform safe and unpowered (or only minusculey...nondamaging, anyway!) tests by first disconnecting the main Battery to remove the main source of power, then connecting one side of the meter (in Continuity Test Mode) to chassis and the other to the load side of fuse (or to wire suspected of being shorted)...we would expect the Continuity Beeper to be sounding off at this time, confirming a low resistance connection.

If the operator then probes around suspected areas or wires (with an IPT *), or even disconnects suspected loads or connections...when the beeping stops, the short (or a path to the short) has been located!

[*IPT is short for: Insulated Poking Tool...typically a give-away, one-use, bamboo Chop-Stick, initially from my local Sake Cafe, and now from my collection: (See: Repurposing Prevents Alzheimer's [Not yet on-line!])]

Hint: It is also a good idea to start looking at the last place work was done...9 times out of 10, this is where the problems will be found! (See: http://www.sw-em.com/Battery%20Notes.htm#high_parasitic_load_audio_amp )

The nice thing about the Beeper Technique is that one can fully concentrate on the area one is working on, while simply listening for the beeper to stop sounding, and this technique is particularly useful while in contortions behind a P1800 dashboard, [I recently was impressed by the term "Dashboard Spelunking" in describing working on 1800 Instruments...] or in the case of intermittent shorts, because the intermittency would be apparent in the beeper action as we are probing around the suspected areas.

--------------------------

Speaking of locating electrical shorts...Fuse your Cigarette Lighter! See: https://www.sw-em.com/Fuses,%20Allocation%20and%20Troubleshooting.htm#Fuse_your_Cigarette_Lighter

--------------------------

A variation of the Beeper Technique, not requiring a Multi-meter at all, is what I call the "Gru Technique". This technique substitutes a "Liiight Bolb" for the Beeper...it allows a lamp to be used as the "short indicator". Any 12V rated lamp will do, the lower the wattage, the lower the test-current (the 12V lamp within a "Test Lamp" would work just fine, just (**don't be fooled!)! The "Liiight Bolb" can be temporarily connected in place of the fuse which blew...and it will be fully lit with modest, non-damaging current from the main Battery, which is left connected, while the short is occurring while suspected harness or mechanical areas are probed, and it will extinguish when the short is removed...not nearly as cute as hearing the beeping stop, but same useful principle!

** Don't be fooled by a low wattage Test Lamp which might be on (a little) because it has partial voltage on it. Test Lamp should and will fully lite to indicate a short!...if it is lit less than fully, another lamp or electric load may be passing the Test Lamp's current to chassis, splitting the voltage with it, so both would be partially energized...no worries or chance for damage if this occurs, again, just don't be fooled in your troubleshooting efforts!!

-----------------------------------

Practical experience: This technique worked well while troubleshooting a blown Taillight Fuse on a 544 a long time ago...every time one would step on the Brakes, a fuse would blow...it turned out to be a result of a dry-wall screw being used to secure the Taillight Assembly. The screw was so long, that once inside the body, it kept right on going into the assembly harness...reader can guess the rest!...proving once again that electrical repairs should only be performed with care and by qualified personnel, not carpenters (no offense to carpenters intended!).

See also: Electrical Carpentry

-----------------------------------

Troubleshooting Directional Signals A typical problem is: A directional blinker quits working!

Bulb Failures: It's always a good idea to check the simple things first...getting an engine replaced just because you ran out of fuel is equally bad (and expensive!) practice!...and to also take into account other bits of relevant information available at the same time. In the case of the blinker, that means: Even though blinker is non-working, can the tell-tale clicking of the blinker element still be heard from under dashboard?...is the dashboard indicator blinking (possibly at an abnormal rate)?...and the other lamp on that side is blinking as expected. If the answer to all of the above questions is yes, a closer inspection of the suspect lamp is in order. One could start by removing the lens at that corner and just looking at the bulb. Proceed with a visual inspection only.

If one finds a bulb which has soot plated on the inside of the glass envelope, the bulb is due for replacement. The soot is a result of particles of the incandescent filament having burned off, and combined with oxygen which has found its way past the bulb seal, the filament may even still be lighting fine, but the light is not making it through the blackened glass! Finding the glass envelope looking dark or mirrored is a similar situation where the metal of the filament has plated onto the inner surface of glass. The process is called "gettering" from vacuum tubes, as the particles are captured and "gotten". Link: https://en.wikipedia.org/wiki/Getter). Finally, an open filament will obviously cause a bulb not to light either. In all of these cases, simply replacing the lamp will restore function.

Connection Failures at the Lamp Socket: If however, the bulb doesn't look abnormal (and has continuity when checked with an Ohm-Meter), a poor connection outside the bulb may exist. If we remove the lamp, just the action of moving the bulb alone may restore a marginal connection and allow it to work...for a while. That is why I prefer a power-up test before bulb removal here (a process which might disturb and even fix an iffy connection). Turn IGN to the Accessory Position 1 (Link: http://www.sw-em.com/ignition_switch_key_breakage_tech_article.htm#ignition_switch_positions_and_function) , activate Directional Indicator, and wiggle bulb in its holder...sometimes, the bulb will start working for us right there! This confirms a connection failure. Turn IGN OFF, remove bulb and inspect for green or white oxidation dust on bulb base and/or socket...this is often the cause of a poor connection...clean the metal surfaces of bulb base (emery cloth, wire brush) and socket (rolled up emery cloth, mini wire-brush) to shiny fresh metal...especially in the area of the locking pins on the bulb base (because these are typically the actual current path, after they are pressed into a receiving groove in the socket under spring pressure), and when everything is nice and shiny-clean, put a film of ACZP on the bulb base (especially on those locking pins) and reinstall in the socket. Perform another power-up test to confirm your repair and reinstall the lens.

General Blinker Failure: If on the other hand, none of the blinkers are functioning, no clicking of the blinker element can be heard, and the dashboard indicator is showing no signs of life, it might be better to look a bit further up the path...like to Fuse 1 or even the blinker element. In the case of an open Fuse 1, the blinker failure would be associated with non-functioning fuel gauge, wipers, ventilator and a brightly lit AMP Indicator.

Blinker elements used on vintage Volvos were two connection types (this type has no separate output for the indicator), and these must be replaced with two connection types. Be aware that three connection types are apparently not compatible, as this owner found out here...Link to Brickboard Thread (...can't find it at the time of this writing).

As can be seen in a detailed extract of the Wiring Diagram following, power to the Indicator is supplied by the Directional Indicator side circuit, selected with the Directional Lever, and the other side of the Indicator completes the circuit to chassis through the other side’s two bulbs. The technically experienced reader will observe that this puts the dashboard Indicator in series with the two Indicators on the fender which reduces the voltage at the dashboard Indicator (most voltage drops across dashboard indicator, therefore lighting it, only a small amount of voltage drops across the effective resistance of the two bulbs at the fenders, not enough to light them, the effective impedance and Ohms Law is the reason, but a detailed derivation and presentation are not necessary here)...the point is, this is correct, and that also explains why the dashboard Indicator bulb burning out is so rare - the bulb is being operated at an under-voltage and being “soft started” (that is, not being slammed ON with an instantaneous application of the full voltage), and will therefore likely outlast the driver, and maybe the pyramids!

Note: The Blinker element used in the self-contained E-Flasher Switch (where the blinker element is located on switch's back end, and which I prefer for retrofitting on the vintage vehicles LINK) is a three connection type.

This info was extracted from the standard 122

Wiring Diagram located in the back of every Service Manual, and even the Owners

Manual.

A closer look at the detailed circuit diagram shows for instance, that the path of directional signal current is routed by way of the (P) terminal of Wiper Switch and Fuel Gauge. This “daisy-chain” routing explains that if the directional signals don’t work, and we are trying to locate the open circuit which is causing the problem, it may be sometimes become necessary to check places which are not immediately and intuitively involved...here is where some careful and thoughtful interpretation of the wiring diagram is required...and a little logic (or common sense) wouldn't hurt...so if none of the directional signals are working, the supply side, like blinker element and Fuse 1 would be a good place to investigate... If on the other hand, just one corner is not blinking (and the corresponding side on the other end of vehicle is blinking), just that one bulb may be out because of simple bulb failure. Don't forget those six pin connectors ...they're highly reliable , but could probably benefit from being pulled apart and pushed back together a few times...and treat with a dab of ACZP. See also Link: http://www.sw-em.com/voltage_drop_in_headlights_power_in_hex_connector.htm )

Happy troubleshooting!

--------------------------------

See also: Troubleshooting technique of Roffe and Bjorn

------------------------------------------------------------------------------

Troubleshooting Fuel Gauge Link to Sw-Em tech article about Fuel Gauge: Fuel Gauge

Background: Fuel gauge itself is a reliable dual coil instrument designed by VDO. It works by electromechanically balancing the magnetic field created by the sensor current against a magnetic field created by an internal reference current. Link to additional info: Drehspulinstrument datasheet. This design is accurate and quite immune to variations in the supply voltage...internal temperature compensation was also built in...quite a good design for automotive application. Inaccuracy stems predominantly from the nature of sensor used and the geometry of its lever arm with respect to the actual fuel level. Often gauges are very non-linear...Full...Full...Full...Full...Half...Empty is the way they like to read. One can try to play with the float lever, but I just try to get accustomed to the way each particular car reads.

Correct operation: The sensor nominal value is from 0-10 Ohms when tank is Empty to 180 ohms. when the tank is full.

Erroneous readings:

Bouncing readings: Sharp, instantaneous bouncing can be a result of an instantaneous resistance change caused by a scratchy contact of the slider arm to the resistance element within the sensor. Surface corrosion can also build on the resistance wire of a stored vehicle, preventing a good contact initially after returning the vehicle to service...this may correct itself as the slider cuts through the corrosion and cleans it away. Erratic readings may also be caused by wiring problems between gauge and sensor, or even a poor negative connection (made through one of the gauge mounting nuts), so both of these should be clean and snug.

Soft bouncing is typically the result of the float bouncing around as the fuel sloshes around the tank during “spirited driving”.

Gauge read Full whenever Ignition is turned ON.

Caused by the highest resistance to chassis/lowest current on the sensor line...this can also be cause by an open connection anywhere along the path...including an open chassis connection to the tank or sender housing.

Gauge read Empty whenever Ignition is turned ON.

Caused by the lowest sensor resistance to chassis/highest current in the sensor line...again, good chassis connections are required.

Fuel Gauge connections showing a bit more detail than usual.

Link to Brickboard thread on Fuel Gauge: http://www.brickboard.com/RWD/index.htm?id=978149

-----------------------------------------------

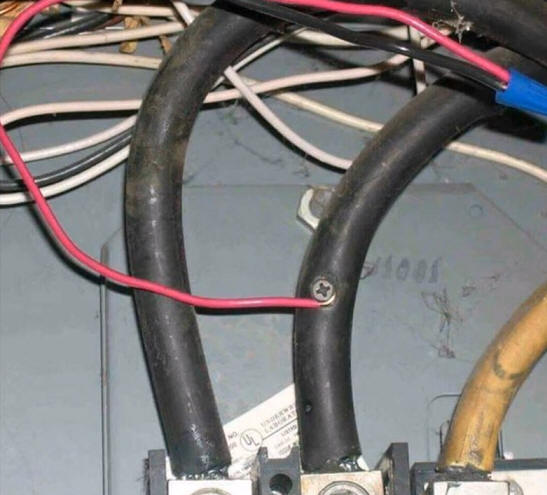

Link: 1800 "Smoke in the Cockpit" and Remote Troubleshooting

With some good logical and systematic troubleshooting, all performed remotely under the author's direction, this P1800 owner in the UK was able to locate and correct the source of "smoke in the cockpit" (Yikes!). Link to thread: Dodgy Wiring, HELP "My P1800 started smoking from behind the steering wheel today". http://www.volvoforums.org.uk/showthread.php?t=89108

Unfortunately, it looks like some of the associated pictures are no longer there...I'll see if I can get them and include them here as it is an example of good troubleshooting technique with a successful outcome, which might help another P1800 owner.

Bottom line and cause of the smoke was twofold: The Lucas Footswitch had been previously touched in an attempt to make repairs did not have an insulated bottom cover, which allowed one of the wire terminals to touch the chassis mounting surface...one can guess the rest!

I am in the process of disassembling and reviewing both Bosch supplied 122 and Lucas supplied 1800 Footswitches, results of which will surely be published in a Tech Article...watch this space...!

TO BE REMOVED AND REPLACED WITH A LINK TO SEPARATE ARTICLE SMOKE IN THE COCKPIT

Link: https://www.sw-em.com/Smoke_in_the_Cockpit!.htm

-----------------------------------------------

Reference:

Electrical modifications should only be performed by highly qualified

individuals!

-----------------------------------------------

External material sources are attributed. Otherwise, this article is Copyright © 2015-2021. Ronald Kwas. The terms Volvo, and VDO are used for reference only. I have no affiliation with any of these companies other than to present my highly opinionated results of the use of their products here, try to keep them working for me, and help other enthusiasts do the same. The information presented comes from my own experience and carefully considered opinion, and can be used (or not!), or ridiculed and laughed at, at the readers discretion. As with any recipe, your results may vary, and you are, and will always be, in charge of your own knuckles!

You are welcome to use the information here in good health, and for your own non-commercial purposes, but if you reprint or otherwise republish this article, you must give credit to the author or link back to the SwEm site as the source. If you don’t, you’re just a lazy, scum sucking plagiarist, and the Boston Globe wants you! As always, if you can supply corrections, or additional objective information or experience, I will give it a careful technical scrutiny, and consider working it into the next revision of this article...along with likely the odd metaphor and probably wise-a** comment.