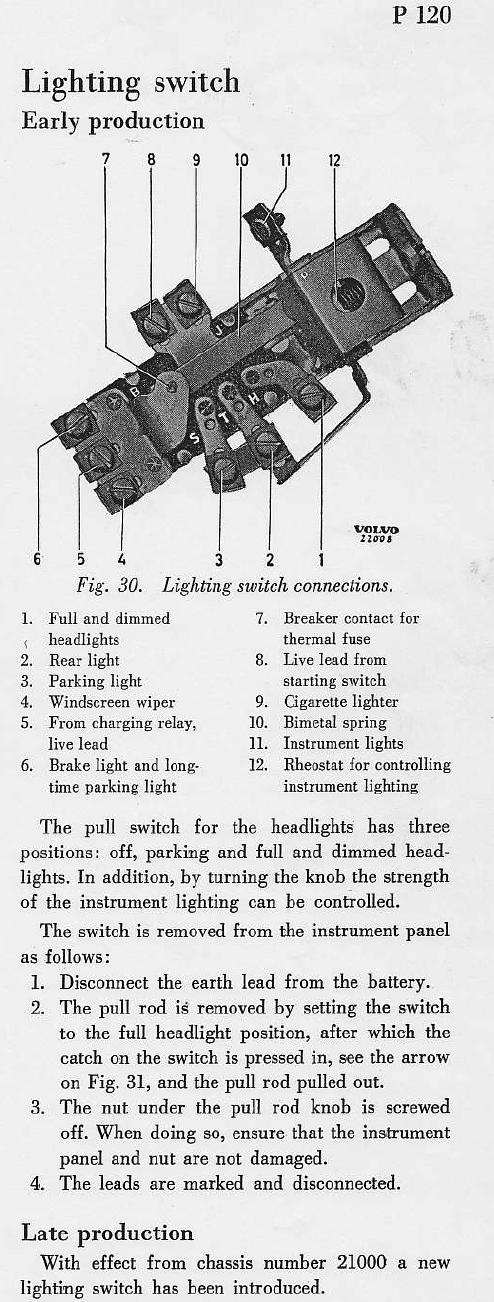

Picture Source: Volvo Service Manual, Section 3 Electrical system P120 12V.

Amazon Lightswitch Review and Notes

First Published Apr 2020, R. Kwas, updates on-going [Comments Added]

-----------------------------------

Removal of Lighting Switch

from Dashboard

Inspection, Disassembly and Evaluation

Resistance checks of Riveted

Contacts

Reassembly

-----------------------------------

Link to Light Switch info on 1800 vehicles: https://www.sw-em.com/1800_Light_Switch_Wiper_Switch_Fan_Switch_Drawing_Corrections.htm

-----------------------------------

With the popularity of people adding "Relay controlled Headlights", I thought I'd take a closer, critical look at the Original Equipment Lightswitch. My position has always been (and will likely continue being [...definitely after the findings here!]) that the OE Lightswitch is perfectly adequate for controlling headlight current, and there is no technical reason to change over to "Relay controlled Headlights". Dim or yellow headlights are typically caused by them not operating at full voltage because the general system voltage is down, or due to a voltage drop along the current path in the Headlight wiring, but not necessarily at the Lightswitch...much more likely, a poor connection at a connector, or crimp, or even to chassis!

These notes will apply to the 12V Lightswitch on Amazon Vehicles only, and not

1800s, as these vehicle had entirely different Lucas (GAG!)

supplied Lightswitches fitted. [See a

review of the 1800 Lightswitch here:

1800 Light Switch

Disassembly, Review, and Reassembly

]

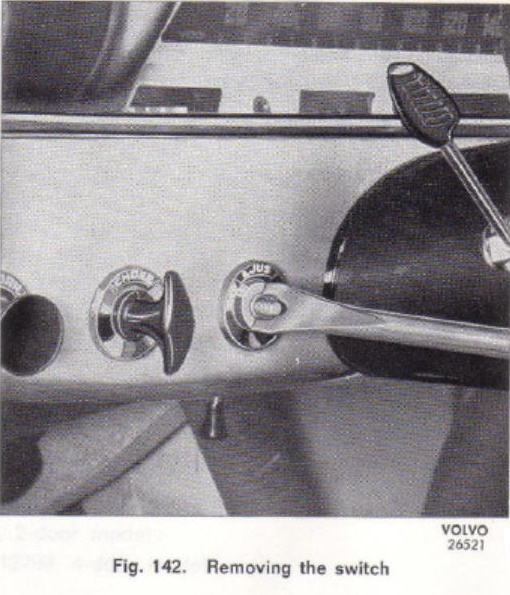

Removal of Lighting Switch from Dashboard:

A special tool which resembles a large flat-blade screwdriver with center area removed to clear shaft, is used to unscrew the chromed bushing nut. A needle-nosed pliers, used CAREFULLY, will do the job also.

Picture Source: Volvo Service Manual, Section 3 Electrical system P120

12V.

Inspection, Disassembly and Evaluation:

Switch as removed from vehicle. The Knob and chrome retaining nut, have

been threaded back on their respective shaft and bushing. The metal

housing exhibits some surface rust, but is generally substantial enough to be

able to be cleaned up before installation.

|

|

|

Business-end-view, showing terminals with designations per

the

DIN

72552 Standard. In addition to

the terminal designations on the switch, which are all shown and accounted for in

the 122 Wiring Diagram, the meticulous observer will notice an

additional 30b (?) marking (next to the enclosure rivet at

Yellow). This marking is

for a switch configuration not used in the Volvo application.

Drilling out (2) rivets allows the metal cover to be removed to gain access

to interior. A supportive, low friction brass bushing doubles as the

mounting bushing in the dashboard, and it also guides the Knobshaft protruding through the enclosure...good

design practice!

Protective enclosure is lifted off the assembly.

First look at the internals. A riveted construction with generously sized,

riveted conductors and straps is evident. The shaft to which the pull-and-turn

knob is screwed has a four-sided insulated section, on which equally generous brass conductors

are located, and at different heights. In this way, connections are a

function of the different switch positions.

Switch Position 0 (OFF). Mega-beefy spring contacts are evident!

These exert a high spring-force on the central, four-sided movable contact

armature, wiping the contact clean in preparation for passing high current, at

each activation, a very good design and execution indeed!! Dimples in the

contacts gently fall, under spring force, into depressions in the contact armature, to

give a defined tactile feedback in each of the switch positions. This

switch is an example of

long-lived superior switch

design and construction!

Switch Position 1.

(Term 30 [Power] is Connected to Term 58 [Parking/Marker Light output]) As the knob is pulled, the central quad armature with its beefy brass

contacts, slides along the spring-loaded static contacts, with these connecting the

appropriate points and output terminals.

The Central quad armature is pulled past Pos 2 and removed.

Three fiber thrustwashers are noted on four-sided lower part of Knobshaft,

which extends into lower part of the switch where Wiper of Variable rheostat for

Variable Instrument Lighting is activated.

Note: I did not make any witness

marks to assure it is replaced in the correct orientation (one of four!) on

reassembly (doing so would have been the smart move!), so it would be necessary

to figure this out and insert the armature correctly at that time.

Top view of switch internals with quad armature removed. Some corrosion is

evident, but limited to only where resistance wire connections are made

(Yellows). Because of the

absence of corrosion anywhere else, it can be deduced, that this corrosion is

likely caused by galvanic action of dissimilarity with the (probably Nichrome)

resistance wire. Reference:

https://en.wikipedia.org/wiki/Nichrome

|

|

|

Removing remains of tubular rivets. These will be replaced with bolts and nuts on reassembly.

Inspection of the quad armature, and cleaning with an alcohol wetted cotton swab.

The beefy brass contact wrapped around the quad armature shows minor wear only,

where dimpled contacts have slid on them. These

contacts are in very good condition, exhibiting only modest wear, and would

likely last another 50 years!

Cleanup of thrust-washers, also with an alcohol wetted cotton swab.

Resistance checks of Riveted Contacts:

|

|

|

Resistance checks. Riveted stacks of terminals make a very positive connection between elements of the stack of terminals, but can be somewhat susceptible to interlayer resistance due to corrosion or loosening. No loosening or resistance over 1 Ohm is in evidence during resistance checks of this example. Ideally, low Resistances should be checked using the Four-Wire Resistance Testing, but these look so good, there is little need for more in-depth functional testing of this switch!

PLACEHOLDER FOR INSPECTION OF VARIABLE

INSTRUMENT LIGHTING POTENTIOMETER...BUT NOT ON THIS SWITCH!!

[This would require further disassembly

and contact-rivet removal, which I am leery of on this very nice example of the

switch! I will not further disassemble this switch, preferring to instead

use the FULL Instrument Lighting bypass described here

https://www.sw-em.com/Intermittent_Variable_Instrument_Lighting.htm , which

makes needing to drill out those nice contact-rivets unnecessary! ]

Overall Impression of this switch is that it is a very high quality component, with lots of mechanical and electrical margin, to last many cycles of use, and therefore a very long time! No wonder they easily last 50 years, and failures are quite rare! [In the writer's opinion, this switch doesn't even travel in the same quality universe as a Lucas supplied Lightswitch of the P1800!]

In terms of refurbishing any of the internals before reassembly, nothing really

stands out as needing anything beyond cleaning! After the correct

orientation of the Quad-Armature/Knobshaft was figured out,

ACZP was used to lubricate electrical contacts,

Superlube synthetic grease on all points needing only mechanical

lubrication, and the Knobshaft was replaced.

Pinpoint application of lubes ideal for the particular job.

The housing is replaced, and secured by two 4-40 instrument screws (which have decreased diameter heads which set into the rivet recesses perfectly), and secured with washers and locking nuts.

Chrome securing nut and Knob are reinstalled, and the knob is given several test cycles...with all surfaces newly lubed, it works smoothly with defined detents in the three positions, and turning the knob to move the Rheostat wiper is no longer squeaky. The wire-brushed and lacquered housing is installed.

Reassembled Lightswitch ready for another 50 years of service!

------------------------------------------------------

Links:

-----------------------------------------------------

6V Light Switch:

The 6V Lighting Switch of the 544s and 122s shown below, is of a completely different construction. Because it is clearly a pretty important control on a car, in addition to controlling and passing essentially double the current of the 12V version shown above, I expect Volvo didn't skimp on its construction either (be it either an in-house made or a supplied component), and it is also of very stout construction! If I ever get one of these into my little fingers, I'll do a critical evaluation and include that here for comparison. Anyone with one of these retired switches is welcome to forward it to me for a critical evaluation.

Source: Green Factory Manual for the 122 Electrical section.

------------------------------------------------------

External material sources are attributed. Otherwise, this article is Copyright © 2020-2022. Ronald Kwas. The terms Volvo and Lucas are used for reference only. I have no affiliation with either company other than to try to keep Volvo's products working for me, help other enthusiasts do the same, and also present my highly opinionated results of the use and care of their products here, including ridiculing Lucas for their junk products (they were the chinashit of their day!). The information presented comes from my own experience and carefully considered opinion, and can be used (or not!), or ridiculed and laughed at, (or worshipped!), at the readers discretion. As with any recipe, your results may vary, and you are, and will always be, in charge of your own knuckles, and future!

You are welcome to use the information here in good health, and for your own non-commercial purposes, but if you reprint or otherwise republish this article in whole or in part, you must give credit to the author or link back to the SwEm site as the source. If you donít, youíre just a lazy, scum sucking plagiarist, and the Boston Globe wants you! As always, if you can supply corrections, or additional objective information or experience, I will always consider it, and consider working it into the next revision of this article...along with likely the unique metaphor and probably (likely) wise-a** comment.